Rulon® fluoropolymers are a multi-purpose high-performance group of proprietary, PTFE-filled materials that provide low friction and high wear life. It is capable of withstanding harsh conditions such as aggressive chemicals, dry running and abrasion with the ability to function in extreme pressure and temperature ranges. A variety of Rulon® grades have been developed over the past 60 years for specific custom applications since they can be custom-engineered into bearings, cup seals, wear components, piston rings and other critical parts.

Rulon® components ensure performance, reliability, long service life, and decreased maintenance cost, and downtime.

The first Rulon® blend was developed in the 1950s and used in broad range of applications. One of the oldest and significant applications has been its employment as slide bearings / anti-seismic plates in the Alaskan Pipelines for its non-rusting, chemical resistance, and low-stick slip properties. Rulon® PTFE materials have endured the extremes of Alaskan temperature from the day of commissioning in 1977.

Rulon® Material Marks Over 60 Years of Service

In the 1800s, saddles were wooden bearings used to weigh the top rolls on textile spinning frames. A successful trial was conducted by Ezra Dixon - an industrial pioneer - to optimize the performance of this basic mechanical component, which laid the foundation for Omniseal Solutions' wide-ranging series of Rulon® solutions.

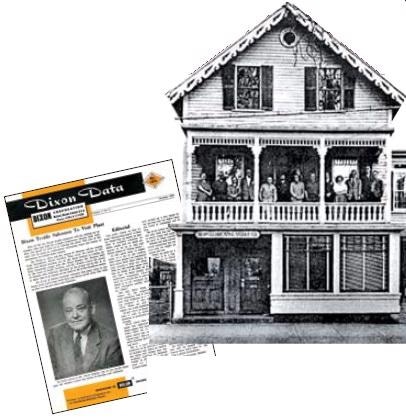

This photograph of Dixon Lubricating Saddle Company employees was taken in the early 1950s at their headquarters on High Street in Bristol, Rhode Island.

After the Civil War, Dixon worked in Rhode Island, installing spinning frames in a textile mill. He came to the realization that a more advanced saddle design could significantly enhance productivity, developing a metal bearing that became the global standard for this vital part. The story of Rulon® actually began in 1957 when the company trademarked the name of a new material that Robert Rulon Miller — who married into the Dixon family — had been investigating. This material used tetrafluoroethylene as a part of a new plastic saddle design, focusing on smoother functioning and longer wear life. The trademark name became Rulon®.

Since the creation of the Rulon® material, first with Dixon Industries Corp., then Furon, and presently Omniseal Solutions, the polymer has been expanded to many varied grades of composite materials with unique properties that serve a wide range of applications and industries.

With transversal research and development centers around the world, the business aims to engineer polymers such as the Rulon® solutions to meet even more challenging applications — lasting in higher temperatures and longer than rival alternatives in the market.

Types of Rulon® Mechanical Components

Bearings

Rulon® composites are suitable for non-lubricated, high-load capacity, enabling the replacement of powdered metal, bronze, and steel in certain applications, and providing longer wear and prolonged operating life. Sleeve, flanged and thrust bearings are available in the common materials: Rulon® J (all-polymeric reinforced PTFE compound designed to work with soft mating surfaces), Rulon® LR (continuous non-lubricating service), and Rulon® 641 (FDA compliance for food and drug contact and USP Class VI certification).

Rings

Solid and split piston rings, comprising of a complete complement of joint configurations, can be manufactured to meet custom specifications, or Omniseal Solutions' engineers can assist customers to design the ideal ring for specific needs.

Tapes

A majority of Rulon® materials can be skived (shaved) into sheets, which can be etched for bonding to other materials or employed as is in a wide variety of applications where friction reduction is preferred. FDA-compliant materials can be applied as non-stick coating surfaces for food preparation.

Basic Shapes

Molded and extruded tubes and rods and molded sheets can be ordered in most of the materials.

Formed Parts

A wide variety of cup seals is available, either cold-formed to preserve the natural memory of the materials or hot-formed to hold a particular shape. These products deliver reliable hysteresis in precision electronic and dust-sealing applications.

Rulon® fluoropolymer solutions are used in applications such as industrial mixers, vacuum pumps, refrigeration compressors/valves, life science pumps, and consumer appliances.

Wear Components

Wear components come in a range of sizes and shapes in addition to those defined above, including pump bodies, wear bands, and pistons for thermally and chemically challenging environments. These parts are usually manufactured to customer specifications.

Case Study: Fuel Dispenser Pump

Rulon® polymer material is used most often in industrial applications because of its long life and low friction. Some plants have to run their equipment constantly, so imagine the significant costs due to downtime.

Image Credit: Omniseal Solutions

This information has been sourced, reviewed and adapted from materials provided by Omniseal Solutions.

For more information on this source, please visit Omniseal Solutions.