Inductively coupled plasma (ICP) analysis involves the ionization of analytes with argon plasma at a high temperature, followed by the determination of the sample’s elemental composition through the analysis of the mass and charge of ionized particles present within the sample. It is important to note that ICP processes can be expensive and complex to achieve, as they often require the use of multiple instruments in order to maintain optimal experiment conditions and acquire accurate data results.

For example, the necessary equipment for ICP analysis can include spectroscopy systems, electromagnetic coils and carefully prepared samples, all of which play a role in ensuring high purity of analyte samples. If these stringent conditions are met, an ICP laboratory setup is capable of detecting almost any element of the periodic table at both trace and major concentrations.

Sample Preparation for ICP Analysis

In a typical ICP spectroscopic array, liquid samples are pneumatically nebulized and passed through argon plasma through a cold flow of gas that vaporizes and then ionizes the sample. Since large particles are not suitable for ICP analysis, they are often separated from the analyte cross-flow in a spray chamber, which can unfortunately present a difficulty for researchers interested in performing an ICP analysis of solid samples. Solid samples must therefore be liquefied through dissolution, which can be achieved by either acid digestion or fusion methods.

XRF Scientific provides a broad range of lithium tetraborate (Li2B4O7) and lithium metaborate (LiBO2) eutectic fusion mixtures for ICP sample preparation. These fluxes are non-hygroscopic in nature and are capable of retaining a consistent low water content is maintained at 0.04% throughout fusion processes. In doing so, these instruments successfully maintain excellent sample to flux ratios in an effort to ensure high quality analytical results.

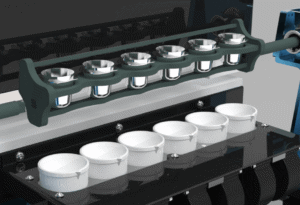

Sustaining these exact ratios is crucial to experiment repeatability and accuracy. As a result, XRF also offers customers a wide range of high throughput flux measurement equipment that can be used to maintain accurate sample preparation parameters. This equipment allow for ICP flux measurement tasks to be achieved with exceptional degrees of accuracy that are within 1 mg, as well as dosing predetermined amounts of a fusion flux mixture into platinum crucibles that can withstand the high temperatures of the dissolution process that can reach as high as 1250 °C.

When the platinum crucible has been dosed with the correct ratio of sample:flux, it is then transferred to a fusion instrument that prepares ICP solutions. Some of the XRF electric fusion machines include:

- xrFuse 1: equipped with a ceramic cradle and versatile holders

- Zero contamination levels

- High degrees of flexibility for both pre-heating and ICP processes

- xrFuse 2: equipped with programmable fusion parameters including a dual-stage cooling process

- xrFuse 6: equipped with a contamination-proof high-purity ceramic chamber capable of performing cold-to-cold operations

XRF offers a comprehensive range of ICP equipment available for various types of specifications. Additionally, product packages are available to consolidate the costs of achieving the highest quality results.

ICP Solutions from XRF Scientific

XRF’s ICP sample preparation solutions are built upon 25 years’ experience with fusion technology. This company has remained dedicated to improving laboratory throughput and accurate results by providing the some of the most accurate instrumentation to laboratories worldwide.

This information has been sourced, reviewed and adapted from materials provided by XRF Scientific.

For more information on this source, please visit XRF Scientific.