While nanosuspensions and microsuspensions are widely-used in the industry, the characterization of the dispersion state, both in the native and concentrated form (such as slurries or vaccines), remains to be a difficult task. Using a typical measurement technique risks the alteration of the dispersed phase or the apparent particle size. This may be caused either by the principle of measurement (such as centrifugation, microscopy, FFF, filtration, or sieving) or the sample dilution (such as DLS, laser diffraction, or PTA). Such case is especially true for samples that contain agglomerates that break down due to various measurement conditions, including sheer stress from pumping, filtration, centrifugation, and flowing, or from heavy dilutions.

Since the industry requires particles analysis in the native suspension form for product development, health and safety tests, or regulatory compliance, this article proposes a method to assess the mean particle size and agglomeration state in concentrated media. The measurements were carried out with well-calibrated polystyrene and titanium dioxide particles.

Method

Easily-traceable polystyrene nanoparticles were analyzed using Turbiscan®. The provided particles were initially prepared in a water solution with a concentration range of 10-3 to 10%v/v.

Dry titanium dioxide powder, supplied by Marion Technologies, was dispersed in distilled water at a concentration range of 10-3 to 10%v/v.

Reminder on the Technique

Based on Static Multiple Light Scattering (S-MLS) technology, Turbiscan® enables the direct measurement of the mean spherical equivalent diameter (d), knowing refractive index of continuous (nf) and dispersed (np) phases, and particle concentration (φ) consistent with the Mie theory:

BS = f (φ, d, np, nf)

With BS for Backscattering Intensity

Other Methods

Comparisons with other methods such as laser diffraction, particle tracking analysis (PTA), and dynamic light scattering (DLS) were also facilitated; however, these methods required sample dilutions and yielded results that could only be obtained at low concentrations (under 10-4% v/v).

Cryo-SEM/TEM seemed to be an appropriate technique for non-dilution measurements. The efficient analytical method was realized by Prof. Dganit Danino of the Nanotechnology Institute Technion in Israel through a comparison of behaviors observed in Turbiscan; however, this technique required qualification for sample preparation (a process that needed to be done with extreme caution in order to avoid the breakdown of agglomerates), sublimation time, and selection of micrograph or picture.

Results

Polystyrene Nanoparticles

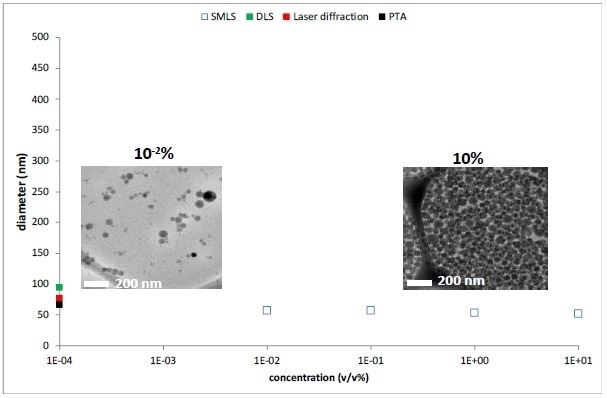

The figure below presents the independence of the polystyrene nanoparticle size from the concentrations. In particular, particles do not aggregate but instead remain separated. Turbiscan measurements are completely consistent with SEM/TEM micrographs at high and low concentrations. Particle size analysis that were facilitated by other techniques (possible only at low concentrations) yielded results that were similar to the data acquired from Turbiscan experiments.

Figure 1. Mean size versus concentration (v/v) for polystyrene particles

Titanium Dioxide Particles

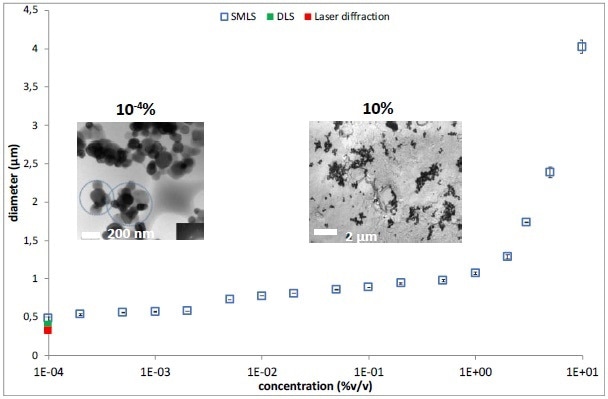

The figure shows that the titanium dioxide particle mean size increases as the concentration level increases. This activity was found to be consistent, with its level of repeatability at 0.5%.

Figure 2. Mean size versus concentration (v/v) for titanium dioxide particles

Cry-microscopy micrographs affirm such agglomeration effects to be in a direct relationship with concentration. S-MLS enables the analysis of samples in their native state, allowing users to monitor the concentration effects on agglomeration. This process cannot be typically observed using other techniques due to sample processing or concentration limits.

Conclusion

A technique that is based on Static Multiple Light Scattering (S-MLS) was proposed as an effective measure of mean particle sizes between 10 nm and 1000 µm in a large concentration range of 0.0001 and 95%. A Turbiscan technology facilitated the study and yielded a good repeatability of 0.5%. The technique is versatile, advantageous, and efficient, with its ability to measure mean particle size for concentrated suspensions in just one click and without sample preparation or dilution.

Other optical techniques such as DLS or PTA could also perform such measurement, but only at high dilution rates. As an effect, agglomerates become denatured, and thus yield an incorrect size of the native particles. Turbiscan LAB also allows samples comparison in terms of physical stability.

This information has been sourced, reviewed and adapted from materials provided by Microtrac MRB.

For more information on this source, please visit Microtrac.