For decades, Ambrell has been partnering with the world’s largest automotive OEMs and integrators as well as Tier 1 and 2 suppliers. As such, the company understands its customers’ need for stringent heating performance and induction heating requirements, especially for the automotive industry. In order to meet these requirements, Ambrell continues to deliver repeatable, precise, and reliable heating for parts and automation systems through an industry-exclusive process called PRECISION MATCHTM.

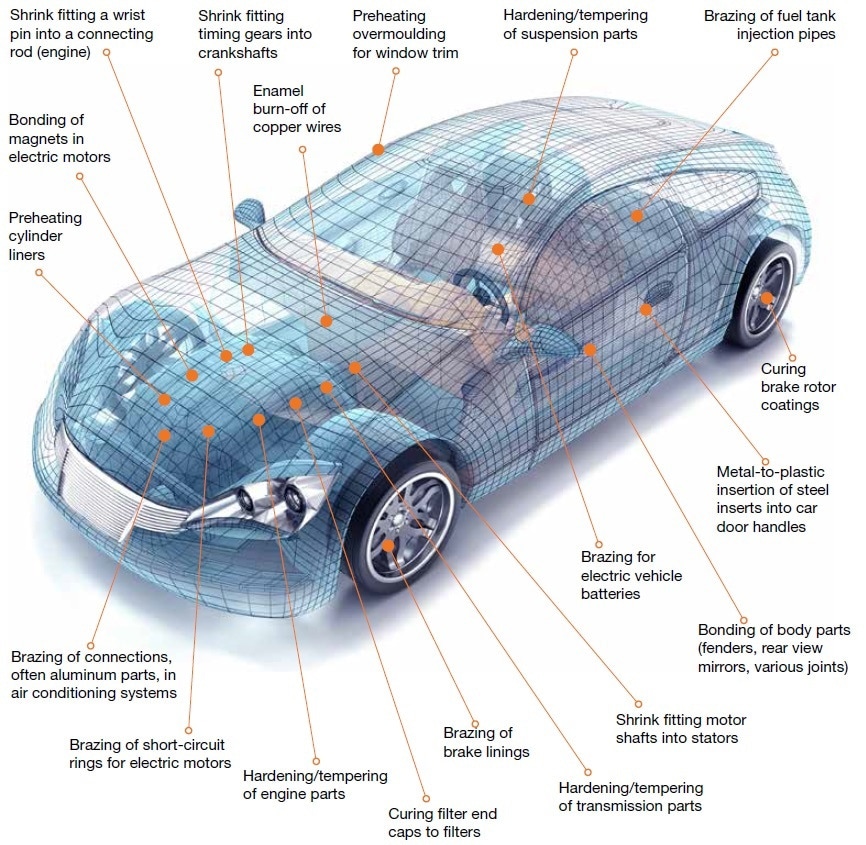

Today, automotive applications represent a third of Ambrell’s overall business and has, therefore, become a core competency that the company provides to its OEMs, integrators, and suppliers all over the world. Ambrell’s innovative induction heating solutions could be used for a vast array of applications—from conventional gasoline and diesel-powered cars or trucks to hybrid and electric vehicles. Ambrell products could be utilized in the most technologically-advanced manufacturing plants in the automotive industry.

Below are some of the automotive applications that Ambrell specializes in:

- Annealing

- Bonding

- Brazing

- Curing

- Forging

- General Heating

- Heat treating

- Material testing

- Metal-to-plastic

- Shrink fitting

- Soldering

Sampling of Induction Heating Applications

Ambrell’s induction heating systems are ideal for a wide range of automotive applications. Ambrell systems are globally recognized for their safe, energy-efficient, and flameless design. Additionally, users get repeatable, precise, and reliable control needed for localized heat that is only directed to areas where heat is required.

Exclusive PRECISION MATCH™ Process

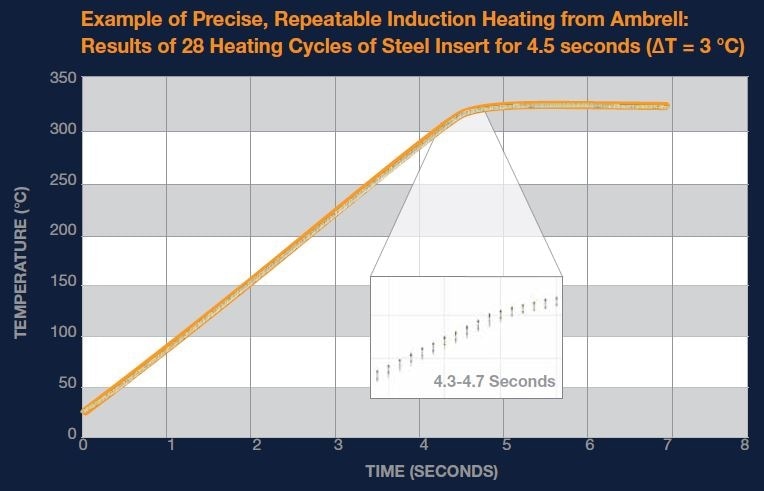

Delivering Repeatable, Reliable and Precise Heating for the Most Demanding Tolerances

Ambrell’s in-depth knowledge and experience in thermal dynamics, electrical engineering, and manufacturing six sigma techniques are comprised of thousands of induction heating feasibility and parts-testing projects simulated and conducted at Ambrell’s renowned Applications Laboratory (also called “THE LAB”). Under the direction of Dr. Girish Dahake, Senior Vice President of Global Applications, the development and implementation of the PRECISION MATCH process was realized.

The PRECISION MATCH process evaluates heating requirements through in-depth mathematical analysis and rigorous laboratory testing to match tolerance specifications accurately. Combining this process with Ambrell’s high-quality induction heating equipment produces the best solution designed to maximize production, improve quality, and decrease process time. Ambrell systems play a key role in eliminating inconsistencies that lead to production downtime or OEM recalls. Furthermore, heating results provided by Ambrell systems become reproducible and could be standardized for global operations.

Automotive Success Stories with Ambrell

Ambrell has an abundance of experience working with automotive manufacturers, integrators and suppliers. The expertise of THE LAB coupled with the versatility and reliability of Ambrell’s EKOHEAT and EASYHEAT systems make Ambrell the go-to provider of many automotive solutions.

Major Automotive Maker Chooses Ambrell for Carbide Brazing Application

A major automotive manufacturer initially chose a system based on purchase price but soon realized that the system reliability and applications support lacked acceptable quality. They contacted Ambrell for a solution that fits their requirements.

Their application involved brazing carbide onto steel for cutting tools for their machine shop. Because they also do a large amount of machining, their carbides wear over time. THE LAB was able to design and produce a solution that met their specifications. After numerous issues with their first vendor, they now have a much better solution for their application.

Integrator Turns to THE LAB at Ambrell for Turbocharger Applications

An integrator needed to build four fully-automated cells for metal-to-plastic insertion applications, involving four parts for a turbocharger, for a major automotive company. Brass inserts were utilized on all parts. The integrator sought help from THE LAB to determine the right systems for their automated cells. The client then purchased one 6 kW EASYHEAT, two 10 kW EASYHEATs and one 15 kW EKOHEAT for the four cells. At present, the systems are in production with impressive five-second heat times.

Tier 1 Automotive Supplier Chooses Ambrell Thanks to Superior Support

A Tier 1 supplier of electronic systems and components chose Ambrell for an application that involved joining filaments of copper wire for terminal and battery cable. The client chose Ambrell due to its CE certification and expertise from THE LAB. The client personally went to THE LAB to discuss specifications. Ambrell’s application engineers were able to successfully design a solution that met the client’s needs, instituting a long-term business relationship with the two parties.

Integrator leverages EKOHEATs for Rotor Curing Application

An integrator for a rotor manufacturer has been a loyal Ambrell customer for years due to the system reliability of Ambrell solutions and the efficient works of THE LAB. The integrator needed an application that involved drying and curing protective coatings on brake rotors. THE LAB has worked to increase their throughout through various projects, an example of which is heating multiple rotors in a single coil using a custom-designed coil and an EKOHEAT.

The Gold Standard in the Industry

Ambrell’s Application Laboratory, commonly known as THE LAB, is where customers’ most demanding and challenging heating application requirements are analyzed and solved. Led by Dr. Girish Dahake’s global team of elite engineers, Ambrell can effectively address many heating process needs. Engineers at Ambrell have evaluated thousands of applications for more than thirty years, and in each application is an innovative and effective induction heating solution that delivers extraordinary results. This consistency makes THE LAB the gold standard in the industry.

Clients are invited to visit THE LAB in either two locations—one in the United States and one in Europe—to be able to experience Ambrell’s state-of-the-art testing facility that is fully-equipped with Ambrell induction heating systems and hundreds of proven coil designs. Additionally, clients may consult with engineers and experience, first-hand, the design process for prototype coils and other effective solutions to maximize any heating process efficiency.

Applications Laboratory Overview

- Access to a wide range of induction heating equipment in THE LAB

- Hundreds of proven coil designs to consult with

- Rapid coil prototyping for unique applications

- Video recording for slow motion studies with available remote access

- Computer software for thermal analysis

- Quenching and closed loop heat-sensing capabilities

- Convenient, easy-to-use online form to acquire a free PRECISION MATCH Lab service

Free PRECISION MATCH Lab Service

Ambrell engineers will design and test the optimal solution for the client’s needed application through the following steps:

- The client sends Ambrell its parts and process requirements.

- Ambrell engineers will analyze the client’s process and heat parts to develop a precise and optimal solution to match client needs.

- The client will receive the parts back for inspection, including a video recording of the induction heating process of the parts and a laboratory report with a system recommendation.

Ambrell Product Family

Ambrell offers a full line of induction heating solutions for various applications. EASYHEAT and EKOHEAT systems are ideal for a number of automotive applications. These systems are CE-marked and manufactured at Ambrell’s ISO-certified headquarters in Rochester, NY, USA.

- An Ambrell system would include the following benefits:

- Precise heating with minimal wasted energy

- Easy-to-use display and control interface

- Moveable workheads for versatile applications

- 100% duty cycle for demanding, automated integrations

- Auto-tuning for heating parts that vary in size, composition, and shape

- Configurable heating profiles for semi-automatic control and process management

- eVIEW induction heating software for easy logging and data monitoring

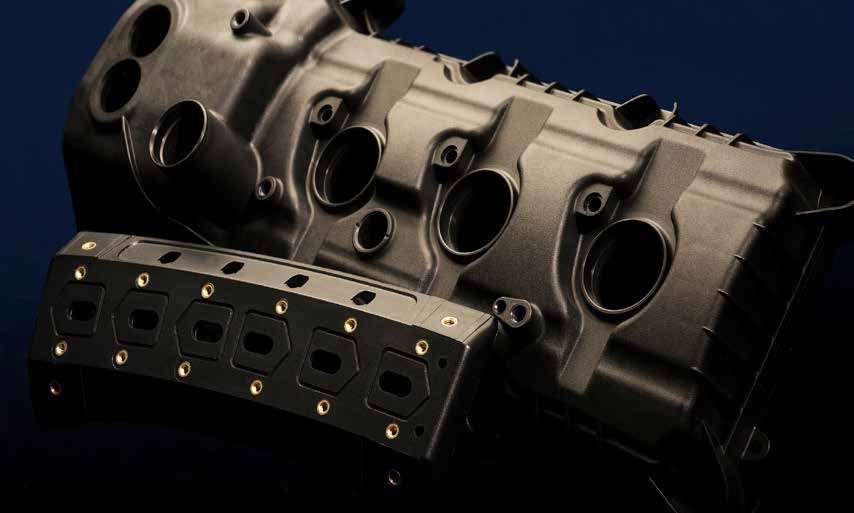

Coil Fabrication

Custom-built coils from Ambrell are available for a wide range of automotive applications.

This information has been sourced, reviewed and adapted from materials provided by Ambrell Induction Heating Solutions.

For more information on this source, please visit Ambrell Induction Heating Solutions.