Metal capillary columns are durable, but the question exists as to whether or not they can perform in terms of their non-reactivity, especially regarding the task of field analysis.

SilcoNert® coated metal tubing is a reliable solution to this question, and this has been explored and analyzed within an article by Jaap de Zeeuw (Restek® Corporation) that compared the performance of SilcoNert® 2000 (referred to as Siltek® and Sulfinert® in the article) coated metal capillary columns.

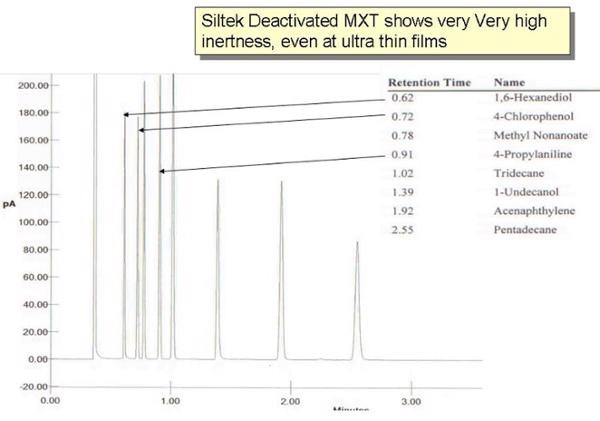

The article illustrates the key benefit of ensuring surfaces are inert when used in chromatography, process separation or process analyzers. It shows that SilcoNert® 2000’s inertness improved both peak resolution and separation, also specifically highlighting (as seen below) that the use of SilcoNert® 2000 also improved the separation of Hexanediol and Chlorophenol compounds.

A SilcoNert® coated metal column offers a range of key benefits. These include:

- Capacity for high temperature analysis within biodiesel and simulated distillation applications

- Precise process analysis with repeatable test results

- Reduced risks of desorption or contamination

- Improved analysis of sulfur with barely any surface interaction and adsorption

- Improved column durability and separation

- Improved direct heating and transfer when compared to non-metal columns

Sulfur Performance

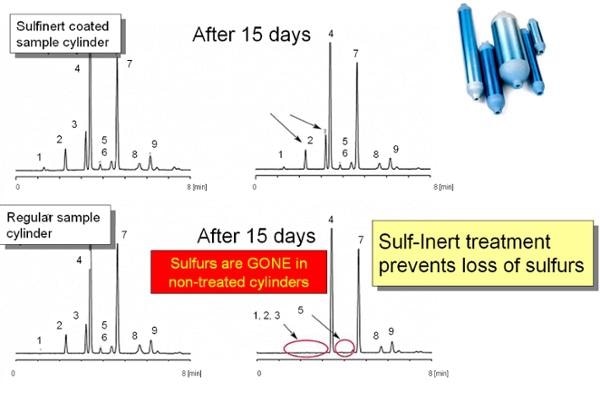

Jaap de Zeeuw’s article states: "The Siltek/Sulfinert deactivation has demonstrated efficacy when accurate levels of sulfur need to be monitored. This technique is not only useful for transfer lines, but also for sample loops, liners, MXT columns, flame jets, etc.; thus, the entire GC system can be optimized to produce the highest possible signal."

SilcoNert® 2000 (Sulfinert®) is a tried and tested solution for problematic sulfur sampling applications. As Jaap de Zeeuw’s study showed, even after 15 days, the sample cylinders coated with SilcoNert® 2000 showed only small amounts of sulfur compound loss, while the untreated sample cylinders showed full adsorption of sulfur compounds.

SilcoNert® 2000 can better improve the efficiency of process analytics, increase process yields and improve overall product quality. It does this by preventing adsorption of a sample or product while preventing surface interaction.

Inertness in Simulated Distillation

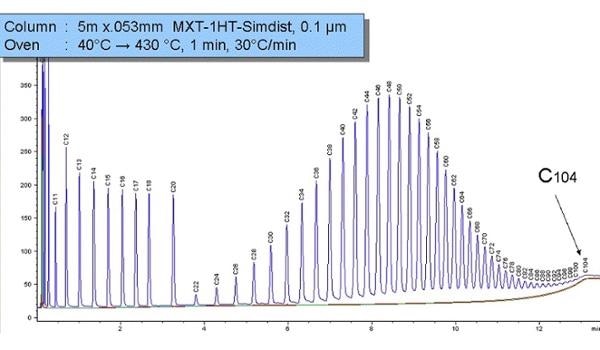

The high temperatures often used within simulated distillation applications can damage fused silica columns, therefore allowing for reactivity with metal surfaces. This reactivity with metal surfaces can alter the accuracy and repeatability of the boiling point, potentially causing variations in retention.

An inert coating that is capable of working at high temperatures is essential within simulated distillation processes, as well as within surfaces used in refinery, gas or oil related analysis.

The graph below shows precision and repeatability of SilcoNert® coated metal surfaces, particularly illustrating consistent peak shapes and elution.

This information has been sourced, reviewed and adapted from materials provided by SilcoTek.

For more information on this source, please visit SilcoTek.