Sustainability is defined as the endurance of a production technique and its lasting ability to harmonize with the economy, society, and the environment. These aspects of the human-ecosystem are persistently varying and presenting new challenges for the established sectors.

The construction industry, for instance, may struggle with its responsibility with the environment and the increase in material demand as the global population continually grows towards an estimated 9 billion people worldwide within the coming decades.

Sustainability and FRP

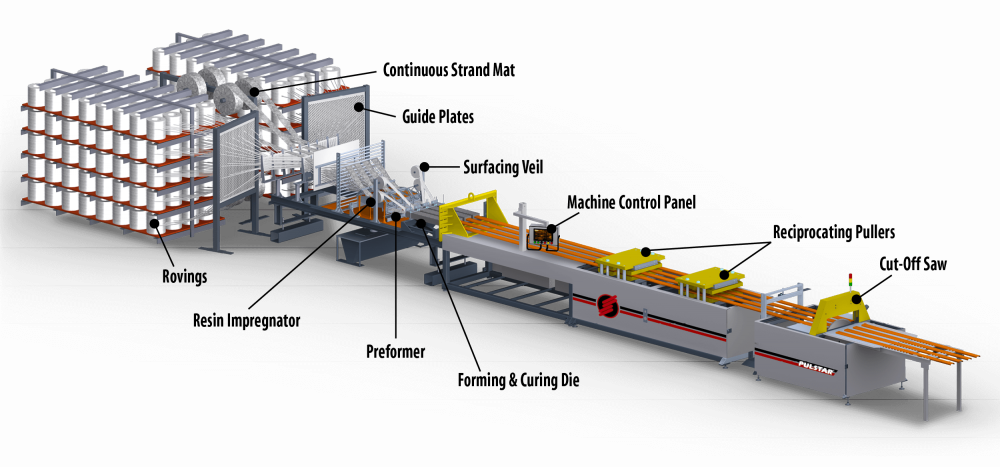

Pultrusion manufacturing techniques were developed for producing lengths of reinforced polymer with constant cross-sections. This provides the raw materials used for cost-efficient alternatives to conventional construction materials such as steel and wood. Originally manufactured because of their lightweight characteristics, FRP products can now contend with the strength of structural steels on a pound-for-pound basis, displaying a reduced weight profile of up to 80%.

They are also impervious to rot and display excellent chemical inertness to an excess of corrosive elements, opposing the natural degradation linked to wooden elements. These mechanical characteristics signify a distinct cutback in energy-intensive maintenance and possible replacement requirements that can have further implications for material recovery and recycling.

Most vital in the context of sustainability, FRP manufacturing represents a radically reduced environmental impact over the traditional material preparation methods. Pultrusion of virgin FRP materials produces less greenhouse gases and use a lesser amount of energy than the manufacturing of steel, aluminum, and concrete.

It has also been confirmed to show a reduced environmental impact over aluminum and steel recycling method in terms of air and water output, and energy consumption.

Regardless of the existing environmental benefits of FRP manufacturing and application, ongoing efforts are ongoing to make sure that modern production methods are in-line with changing global compliances and ethical standards.

This consists of decreasing the energy requirements for pultrusion processes, making improvements in the disposal methodologies for critical solvents, and releasing new material capacities. Naturally-reinforced polymers and bio-resin FRP products are now starting to appear in existing product catalogs, supporting the efforts towards true sustainability in the manufacturing sector.

Strongwell’s Sustainable FRP Commitment

Strongwell is dedicated to construction and manufacturing changes that are both suitable and sustainable. All the facilities work within strict environmental parameters with audited confirmation of their FRP production processes and constant evaluation of how to decrease our carbon output.

Strongwell is committed in performing robust life cycle assessments of our FRP products and in making sure that they are sustainably-minded, starting from the time they are manufactured through to their eventual application.

The product range reflects this, with many long-lasting FRP products performing in demanding applications and decreasing the environmental footprints of a broader array of industries.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.