The advanced Process Insights NIR Process Analyzer System was fully implemented for real-time measurement and control of fuel blending to optimize online gas blend capacity, quality, and product flexibility.

The Customer

The customer is renowned for providing flow equipment products, systems, and services to the process, oil, and gas industries. The company’s equipment is used for measuring, controlling, and directing the product flow into industrial applications such as drilling, pipelines, and unconventional production.

The Project

The customer built a blending facility and terminal automation system for marine fuel oil and high-speed diesel to accommodate international standards in South East Asia. The aim of the project was to improve the storage capacity of a fuel terminal to 300,000 kiloliters, with a dock capacity of LR 100,000 DWT.

This upgraded fuel terminal contains a mogas [automobile fuel] blending facility that boosts the flexibility of premium imported product of naphtha and high-octane mogas [RON 92].

This terminal also enables the company to play the part of both a blending and storage facility provider, and also serve as a mogas super terminal to support the national mogas /premium fuel stock for their oil trading business across South East Asia.

The Problem - Automatic Fuel Blending

A packaged online analyzer system was required by the customer for use in their fuel blending process. In an attempt to boost their production and storage capacity, the company decided to go with an automatic fuel blending system that could accommodate marine fuel oil (MFO), diesel fuel, and automotive fuel.

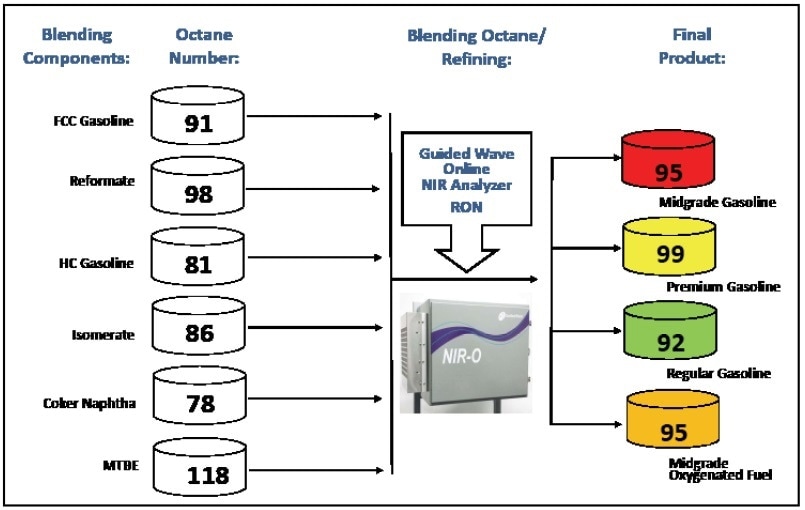

As part of this automatic fuel blending system, the company employed a dual-analyzer system to determine both the RON (or cetane) and vapor pressure together for optimum blending, which enabled them to improve their product offering and allowed the terminal to be multifunctional as planned.

The Challenge – RON Model Fine Tuning

A standard application for online near-infrared (NIR) spectroscopic analyzers, such as NIR-O of Process Insights, is the determination of fuel octane numbers (i.e. RON, MON). These analyzers have a number of advantages over offline laboratory CFR engine octane determinations. NIR analyzers are more precise, faster, have reduced safety problems, reduced operating costs, and also offer real-time information to enable blending control.

For this project, the customer’s required specification included an unusual and very wide RON range for the feed stocks (RON of 70-100+). The objective was to blend expensive high octane feed stocks with less expensive low octane naphtha and at the same time maintain the required octane levels and reduce costs. Local sample collection was needed to fine tune the initial calibration for this expanded range.

The Smart Choice

The customer approached Process Insights due to the latter’s extensive history and expertise in process analyzers for fuel blending. Process Insights’ Dual-Beam Grating (DG-NIR) technology offers long-term stable readings providing laboratory grade results from a process analyzer:

- Removes almost all common mode drift problems

- Very high signal-to-noise ratio; improved detection of trace components

- Ability to read multiple streams and multiple points; up to 12

- NIST traceable wavelengths

- Meets ASTM 6122

The Solution

A starting calibration, offered by Process Insights, was common in nature for this purpose. By adding locally collected data from the site, the starting calibration can be easily adjusted in the field.

After installing the Process Insights analyzer system and collecting the local samples for RON and distillation points, the calibration can be adjusted to these specifications using CAMO’s Unscrambler® software. The final results surpassed their expectations, offering them with even better manufacturing flexibility and a broader source of raw products to use. The entire system has been in operation for over six months, with extra products to be added to this automated blending system.

Control One Can Measure

By associating with Process Insights, customers gain the benefit of more than three decades of experience in stream sample analysis and online process monitoring. Process Insights provides a complete solution that includes components that are optically matched as well as a well-planned calibration method leading to long-term success and savings. The entire product line of the company is designed and developed to offer real-time data of laboratory quality, while flourishing in the most challenging processing plant environments – for control one can measure.

Example: Simple Blending Block Diagram with Process Insights' NIR-O (DG-NIR) Analyzer

This information has been sourced, reviewed and adapted from materials provided by Process Insights – Optical Absorption Spectroscopy.

For more information on this source, please visit Process Insights – Optical Absorption Spectroscopy.