Interview conducted by Mychealla RiceSep 14 2018

Interview conducted by Mychealla RiceSep 14 2018In this interview, Jesse Bischof, Ph.D., R&D scientist, from SilcoTek talks to AZoM about their range of Bio-inert coatings that are making high performance liquid chromatography (HPLC) applications better.

Tell us about the common problems high-performance liquid chromatography applications can face?

Corrosion and inertness are two of the most common problems that SilcoTek’s coatings can address. Ideally, a chromatographer would have any combination of solvents and buffers available to perfect their HPLC experiments. Unfortunately, numerous solvents can cause corrosion issues to the components of the system, whether they are made of stainless steel, titanium, or PEEK and it can handcuff a scientist into using solvent systems that cannot give them the optimum results.

As for inertness, most systems are made of stainless steel. While this steel provides a robust material that can handle the high pressures involved in HPLC, it is quite a reactive material. Trying to analyze materials such as proteins, chelating molecules, sulfur-containing molecules, etc. can be quite difficult due to them sticking to or even reacting with the stainless steel rather than flowing through the system.

Hydrophobic Coating Demonstration - Dursan® from SilcoTek®

SilcoTek provides a bio-inert coating solution. What sets it apart from others on the market?

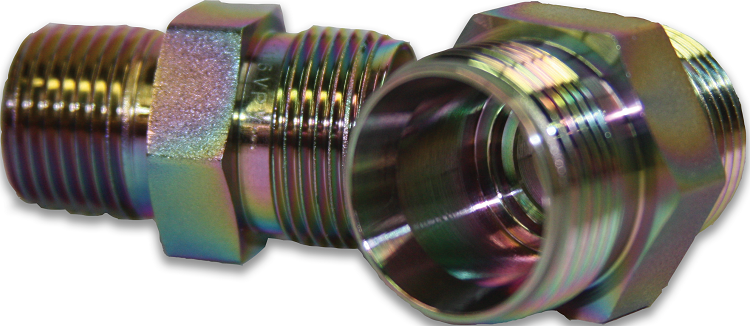

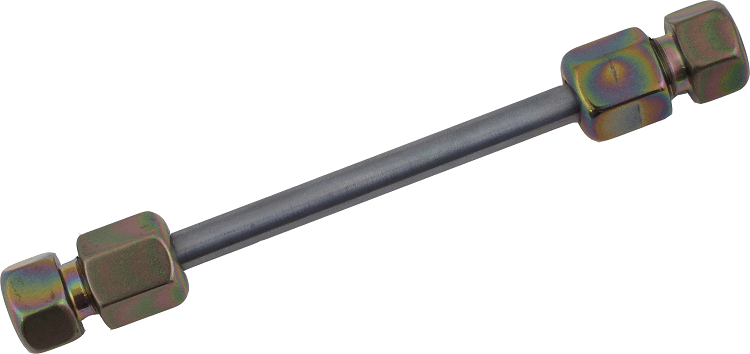

As far as coatings are concerned, SilcoTek’s coatings are unique in the way that they are applied. Many coating technologies such as diamond-like carbon, ceramics, epoxies, or polymer applications are applied via line of sight techniques, meaning only the part that is facing the source of the coating can receive the treatment.

Our technology can conformally coat complex geometries including those with small tortuous pathways such as frits. The other unique part of our coating is the control over the thickness that we have within those complex geometries. All of our coatings are sub-micron, so they will not have an effect on tolerances on larger pieces such as columns, and back pressures will not be an issue. Within frits, the coating is tens of nanometers thick as to not disrupt the flow within the frit network.

Tell us about the features and benefits of the bio-inert coating solutions?

Dursan is a silica-like coating. It provides excellent corrosion resistance to most acids and even functions well in high pH environments. Through a collaborative study with Abbott Laboratories (published here), we found that Dursan has excellent protein release properties.

When exposed to BSA, mouse immunoglobins, and normal human plasma, a Dursan coated stainless steel part sees virtually no proteins sticking to the surface where a bare stainless steel part sees significant protein fouling. It is even on the same level of anti-fouling as a fluoropolymer, except when exposed to sonication, the fluoropolymer tends to get damaged and reveal stainless steel spots.

Dursan is molecularly bound to the surface and does not delaminate under sonication. The benefits of having a bio-inert coating include more accurate results, faster analysis, and less chance of false positives due to protein carry-over effects.

How does Dursan® compare to current bio-inert solutions?

Current bio-inert solutions are titanium and PEEK. There are certainly other solutions available, but those are the two biggest ones that are widely available. As far as bio-inert performance is concerned, beta tests by customers have shown that Dursan coated stainless steel is comparable or in certain situations better than both titanium and PEEK, but there are other benefits as well.

Titanium is a much more brittle material compared to steel and there are certain solvents that corrode and/or make titanium much more brittle. Also, most HPLC instruments are already made of steel, so adding a coating onto steel parts is much easier than re-machining all of the parts out of titanium.

PEEK is a polymer that has bio-inert properties. It’s flexible and lightweight, but it cannot handle high pressures or high temperatures. Additionally, a large number of organic solvents can cause the polymer to swell which can cause back pressure problems. Dursan provides the same bio-inert properties as titanium and PEEK, but can be applied directly to stainless steel and will not experience the same issues seen with current solutions.

What role does bio-inert coating play in HPLC applications?

HPLC is all about getting analytes separated as quickly and efficiently as possible. In the case of protein and other biomolecule analysis, the difficulty lies in the interaction between the analyte and then the components that make up the flow path of the system. Any exposure to metals or other active sites may cause the proteins to stick to the surface of that flow path.

This leads to peak tailing and potential carryover issues in subsequent analyses. There are also times where the adsorption is irreversible, and when scientists are attempting to do quantitative analysis of these proteins and molecules, that adsorption can have a massive impact on the results. By making the flow path bio-inert, these problems no longer need to be addressed.

What difficulties does the coating eliminate in HPLC applications?

The coating acts as a barrier coating between the flow path and the sample while still allowing the instrument to be constructed from stainless steel. With the coating in place, you now have the robustness of the stainless steel, along with the bio-inertness of the Dursan coating. It’s the best of both worlds.

Is Dursan® a corrosion resistant HPLC coating? Why is this important?

Dursan is corrosion resistant. In our immersion testing, a Dursan coated stainless steel coupon will have similar corrosion resistance to alloys such as Hastelloy, an alloy specifically designed for corrosive environments. This is important for two reasons. First, it improves the lifetime of the equipment, and it may open up options for scientists to utilize solvent systems they may not have considered trying in the past.

Second, when a part starts to corrode, it will introduce metal ions into the system. Proteins and biomolecules are very sensitive to metal ions, so keeping the two away from one another will help with consistent analysis.

Protein carry-over and false readings are common problems while improving instrument durability. Is this something Dursan® can improve? How?

These are common problems, especially when an instrument is utilizing an autosampler. The needle that is used for the injection is dipped into sample after sample, and any carryover may lead to false readings. I actually experienced this issue when my daughter was born. She and a few other children tested positive for a high level of a particular protein at birth. The pediatrician told us that she had never seen so many children test positive in such a short window. It turned out that there were about 3 or 4 other children that had a false positive due to this protein carryover issue.

Dursan could have solved this problem by having a surface that proteins cannot stick to and during a rinse cycle, all of the proteins are removed from the autosampler.

Can Dursan® improve bio-analytical and LC system corrosion resistance? How? Why is this important?

The application of Dursan to any system that may see chemicals that are corrosive to steel such as chlorides, bleach, or certain acids would be a benefit to the longevity of the system. As stated before, this helps to keep the instrument in proper operating condition and also keeps metal ions out of the solution that is being analyzed.

What does SilcoTek’s bio-inert coatings mean for the future of HPLC applications? Are there other applications that can benefit from it?

SilcoTek saw one of its other coatings, SicoNert 2000 (formerly Sulfinert), get adopted into the GC world and provide inertness at levels that were previously unattainable. We hope to see the same thing happen with Dursan in the HPLC community. We believe it will lead to better analysis across the board including much lower detection levels, faster analyses, more reliable results, etc.

There are numerous applications of Dursan outside of the HPLC world. It was originally developed for oil and natural gas downhole sampling, it shows great release properties in the plastic extrusion and mold release community, and with its anti-corrosive properties, it has found a home in numerous industries including automotive, aerospace, food and beverage, as well as offshore and marine environments.

Where can our readers go to find out more?

All of this information and more can be found at www.silcotek.com. If you have specific questions or would like to discuss unique applications of our coatings, you can e-mail [email protected], and one of my coworkers would be happy to talk to you. More information specifically discussing Dursan’s use in HPLC can be found here.

About Jesse Bischof

Jesse received his Ph.D. in chemistry from Penn State University studying high-pressure chemistry. Jesse's current work involves developing new coatings, improving our existing selection of coatings, and finding new and interesting markets where Silcotek's coating technology could help solve customer problems.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.