During the early 20th Century, Metallurgist Harry Brearley invented stainless steel in Sheffield, UK. It contained approximately 6 - 15 weight % of chromium and 0.2 weight % of carbon. This alloy was first developed to combat the problem of erosion/wear in gun barrels, but its hardness, durability, and stainless properties were noted to be very desirable in other applications such as cutlery and knives.

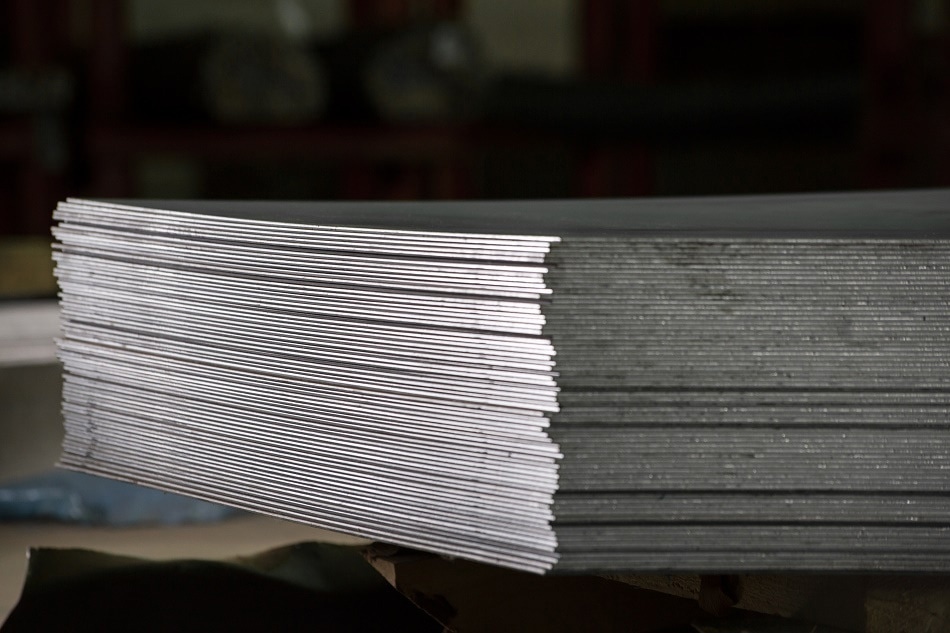

Image Credits: Alexandru Rosu/shutterstock.com

Nowadays, there are numerous different grades of stainless steel for a variety of applications which contain various amounts of carbon, Mn, Cr, and Ni. The available grades of stainless steel can be classified into five basic families using their crystalline structure:

- Austenitic

- Precipitation hardened

- Martensitic

- Ferritic

- Duplex

If you think of stainless steel now, the first thing you probably mention is a ferritic or austenitic metal, in grades 304 316 or 430 as these are the most typically utilized. There are some other very useful grades such as the Martensitic Stainless Steel 1.4057 QT800 (ASTM 431 – SS2321). 1.4057 or Grade 431 is the ‘all-round’ engineering martensitic stainless steel, combining impact toughness with corrosion resistance and good strength.

1.4057 QT800 Stainless Steel

The exact composition varies for martensitic stainless steel grades. But typically 1.4057 stainless steel will contain: 15 – 17% chromium; 2 – 2.5% Nickel; 0.12 – 0.22% Carbon. It may also have small amounts of silicon, molybdenum, and phosphorous. Brearley’s initial samples of stainless steel were martensitic. These alloys are magnetic and are usually formed in the annealed condition, and heat treated afterwards.

Chromium is the main alloying element of martensitic 1.4057 stainless steel, carrying moderate corrosion resistance to a material with inherently high strength and hardness. Normally, nickel concentrations of 2 – 2.5% are added as a stabilizing element to make sure that a martensitic steel keeps its toughness properties during heat treatment, which allows the fabrication of a number of component types.

Martensitic stainless steels are often forgotten, maybe because compared to austenitic and ferritic grades, they are not in high demand. Though, they often play a huge and often unseen role in modern infrastructure. The strength which is gained by heat treatment depends on the carbon content of the alloy. Increasing the carbon content increases the potential hardness and strength but decreases toughness and ductility.

The higher carbon grades are capable of being heat treated to a hardness up to 60 HRC. In the heat-treated, hardened and tempered condition optimum corrosion resistance is achieved. Other martensitic grades have been created with nickel and nitrogen additions but possessing lower carbon levels than the traditional grades. These steels have improved weldability, toughness, and corrosion resistance.

Why Martensitic?

Martensitic stainless steels are similar to a lot of low alloy steels where carbon is the main element. Usually, steels transform from the ferrite to the austenite state when they are heated. The steel reverts to ferrite upon slow-cooling. Yet, the carbon atoms become trapped in a somewhat distorted atomic matrix with fast cooling through quenching in water or oil. This is known as body-centered tetragonal.

The distortion of the atomic matrix results in the hard-martensitic structure. Adolf Martens first observed the body-centered tetragonal martensite microstructure in 1890. The higher the carbon level the harder the martensite is. Martensitic steels are virtually useless in the as-quenched and un-tempered condition, as they do not have enough impact toughness, they are brittle and unsuitable for engineering applications.

Lower carbon martensitic steels can occasionally be utilized in the as-quenched condition for wear resistance. The heat treatment condition of 1.4057 is QT 800 and it should be hot formed in the temperature range 1100-1800°C.

The most common treatment after quenching is tempering (QT = quench-and-temper heat treatment). This requires heating the steel to a temperature between 200 and 700°C. The temperature and length of time at temperature determines the final properties of the steel. Tempering imparts a combination of resilience and strength. Martensitic stainless steel can also be non-destructively tested using the magnetic particle inspection method, unlike austenitic stainless steel.

Properties and Applications

You obtain a high tensile strength stainless steel resistant to strongly oxidizing acids e.g., salt water and nitric acid with an exceptional blend of wear and corrosion-resistance, high strength, and impact toughness, by using 1.4057 QT 800. Furthermore, 1.4057 GT 800 is weldable and is typically easier to machine than ‘conventional’ austenitic steels. With an ultimate tensile strength (UTS) value over 800 MPa, 1.4057 is perfect for complex engineering projects in marine applications (construction and shipbuilding).

This steel has good machinability and is frequently utilized to fabricate pump and valve parts, bearings, spindles, drive and propeller shafts, fittings, packaging machinery, piston rods, nuts and bolts. Other applications include: gears, valve stems, actuators, satellite parts, conveyor drive systems, hydraulic rams, crane pins, mixing blades, hi-fi equipment stands, seat dampers for boats, and golf clubs.

The martensitic grade 1.4057 is also highly sought after for medical devices and medical tools (surgical clamps, scalpels, and razors). Of all the stainless steels, it has one of the best combinations of high strength, corrosion resistance, and good impact toughness. In the annealed condition 1.4057 has a tensile yield strength of about 275 MPa and so is normally machined, cold formed, or cold worked in this condition before heat treatment to harden.

Military Applications

In the manufacture of military hardware for example small arms, the majority of small parts for weapons are manufactured from stainless steel; the components which are gained are then subjected to final heat treatments or to certain surface treatments.

The martensitic stainless steels such as 1.4057 are ideal for utilization in this way for the manufacture of firearms and their components. Components can be machined and afterwards heat treated. Tempered martensitic steel like 1.4057 offers steel high toughness and good hardness.

Martensitic stainless steel is particularly good for the fabrication of gun barrels. There are two main advantages:

- A higher corrosion resistance when compared to an uncoated, unlined, standard carbon steel barrel. Nonetheless, a bare stainless steel barrel can still corrode due to the high duty cycle and must be looked after due to the finishes applied to the outside and inside of the barrel.

- The second advantage to stainless steel compared to plain carbon steel as it relates to barrels is the ‘toughness’ of the metal. Stainless steels such as 1,4057 are more resistant to abrasion and heat than plain carbon steel. A stainless steel barrel should experience less throat erosion than a plain carbon steel barrel, given identical firing schedules.

Summary

Martensitic stainless steels like 1.4057 have a long history right back to Brearley’s discovery in 1912. Its combination of toughness, strength, and moderate corrosion resistance makes it perfect for a huge variety of applications. Although not employed in large amounts compared to ferritic and austenitic grades, they are a critical part of the stainless steel armory.

References

- EN 10088-2: Stainless steels - Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes.

- http://www.worldstainless.org/Files/issf/non-image-files/PDF/TheStainlessSteelFamily.pdf

- Machining of Stainless Steels and Super Alloys: Traditional and Non-traditional Techniques, Helmi A. Youssef, 2016.

- Advances in Stainless Steels, Baldev Raj et al. (editors), 2010.

- Budynas, Richard G. and Nisbett, J. Keith (2008). Shigley’s Mechanical Engineering Design, Eight Edition. New York, NY: McGraw-Hill Higher Education. ISBN 978-0-07-312193-2.

- Akhavan Tabatabae, Behnam; et al. (2009). “Influence of Retained Austenite on the Mechanical Properties of Low Carbon Martensitic Stainless-Steel Castings.” ISIJ International. 51 (3): 471–475. doi:10.2355/isijinternational.51.471.

- Rodney Carlisle; Scientific American (2005-01-28). Scientific American Inventions and Discoveries: All the Milestones in Ingenuity – From the Discovery of Fire to the Invention of the Microwave Oven. John Wiley & Sons. p. 380. ISBN 978-0-471-66024-8.

This information has been sourced, reviewed and adapted from materials provided by Masteel UK Ltd.

For more information on this source, please visit Masteel UK Ltd