There are certain challenges that medical applications need to overcome in clinical diagnostic applications.

This article will explore:

- How bio-inert coatings prevent test errors

- How CVD coatings improve medical diagnostic equipment performance

- How Dursan can improve corrosion resistance in high tolerance narrow bore tubing and needles

Bio-inert Coatings

If a test chemical or target analyte is taken during medical analysis adheres to the sampling or analytical component flow path it can produce inaccurate results. Any of the issues below can create problems in the diagnostic process and, therefore, potentially affect a patient’s health:

- Adsorption (or reactivity) of flow path surfaces that leads to abnormally low test readings and/or calibration errors

- Carryover of analyte proteins released after rinsing during the following test

- Corrosion of flow path surfaces causing pitting and providing hiding places for test compounds to carry over to following tests

- Lost or limited detection due to protein binding

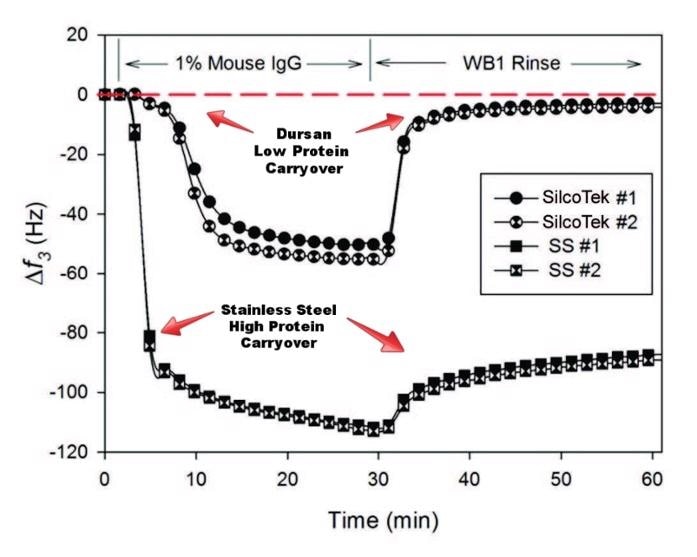

In the following example of protein carryover (published by Abbott Laboratories and SilcoTek® in Applied Surface Science), 1% mouse IgG was applied to an uncoated stainless steel surface and a Dursan® coated test surface. Protein levels were calculated before and after rinse to measure carryover. The results show that the Dursan surface exhibited low protein carryover, while the stainless steel (lower line) retained protein.

SilcoTek Coatings Provide an Optimal Solution

Stainless steel is a substrate that is frequently used in medical analytical equipment. However, this metal is known to be particularly adsorptive to a number of chemical compounds and is susceptible to corrosion when exposed to bleach, salt solutions, and acids.

Two of the main benefits of employing an inert CVD barrier coating in medical diagnostic flow paths are:

- Our coatings supply barrier protection from corrosion, extending the lifetime of substrates and reducing the risk of downstream metal ion contamination.

- Unsurpassed inertness eliminating carryover and enhancing analytical reliability

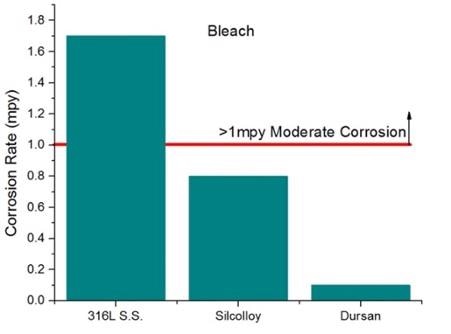

The following is an example of how barrier coatings can enhance resistance to corrosion in precision flow paths, such as needles. Bleach can damage stainless steel flow paths but is an effective cleaning agent. 72-hour bleach immersion tests show notable amounts of corrosion of the stainless-steel surface. The Dursan-coated stainless-steel surface (right bar) reduces the corrosion rate by an order of magnitude or more.

The Benefits of Using Dursan Coating in Medical Applications

Dursan has been found to possess an extremely high degree of chemical inertness when analyzing biomedical components such as mouse immunoglobulin G (IgG), bovine serum albumin (BSA), and normal human plasma proteins.1 Dursan components are also extremely corrosion-resistant in acidic and bleach solutions.

Dursan Versus Other Competitive Coatings

One coating that is frequently used in the field of biomedicine is PTFE (polytetrafluoroethylene). However, Dursan® outperforms PTFE in a number of ways. Below is a short list of the respective coatings’ qualities:

PTFE

- Resistant to corrosive attack

- Thermally stable up to around 200 °C

- Chemically inert

- Relatively soft

- Can delaminate

Dursan®

- Resistant to corrosive attack

- Good wear resistance

- Thermally stable up to 500 °C

- Will not delaminate

- Chemically inert

SilcoTek’s Dursan Coating

SilcoTek provides a robust and inert surface that is both thermally and chemically stable, as well as being resistant to the adsorption of proteins and other bio-based molecules, Dursan coating facilitates higher system performance, exceeding all expectations.

Reference

1 Vaidya, S.V., Yuan, M., Narvaez, A.R., Daghfal, D. Mattzela, J., Smith, D.A. “Protein-resisitant properties of a chemical vapor deposited alkyl-functional carboxysilane coating characterized using quartz crystal microbalance” Applied Surface Science 364(2016) pp.896-908.

This information has been sourced, reviewed and adapted from materials provided by SilcoTek.

For more information on this source, please visit SilcoTek.