This article will examine how the Ultim® Extreme can provide useful electron images using very low energies. Running the imaging at low energies allows insulator samples, such as BN ceramics, to be imaged without needing to coat them with a conductor beforehand.

When characterizing highly insulating ceramics, such as BN, in SEMs the rapid charge build-up that forms under the SEM beam can cause problems. In order to alleviate this the insulating sample must be coated in a conductive material, though this has the disadvantage of changing the sample surface. Another solution is using a partial vacuum, although this has a negative effect on the resolution and magnification levels that can be achieved.

Sample Analysis

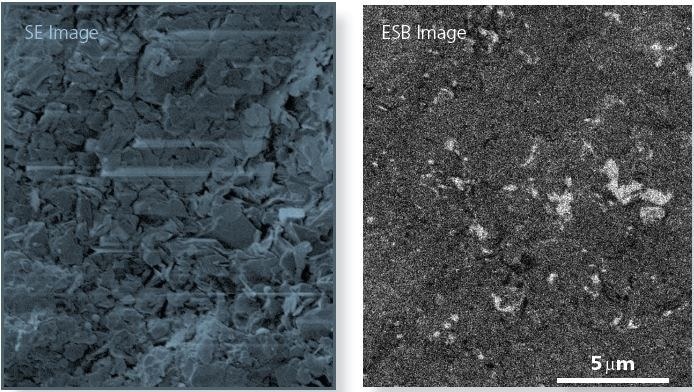

The acceleration voltage of the electron beam was lowered until surface charging was low enough for sample imaging to take place. For BN this voltage was found to be 1.5 kV. The secondary and lens backscatter images for this sample are shown in Figure 1.

Figure 1. Secondary Electron image shows at 1.5 kV sample charging is reduced to a level where imaging the sample surface of BN is possible. In-lens Backcatter (ESB) highlights the presence of particles of higher mean atomic number on the sample surface.

Even at this low potential some sample charging is observed but it is significantly less than the charging that occurs at higher potentials and is low enough to allow the surface morphology to be analyzed.

At the lower potential the backscatter image is more stable and can be used to see regions of different composition in the sample. These regions are made of a material with a higher atomic number than the matrix and are not as obvious in the secondary electron image.

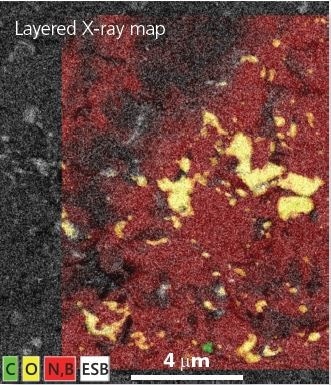

Ultim Extreme is a windowless EDS detector of high sensitivity. The Ultim Extreme provides the unique ability to carry out X-ray analysis at potentials low enough for BN samples. In the example given (Figure 2) a compromise could be found between the accelerating voltage, beam current and charging required to take an X-ray image.

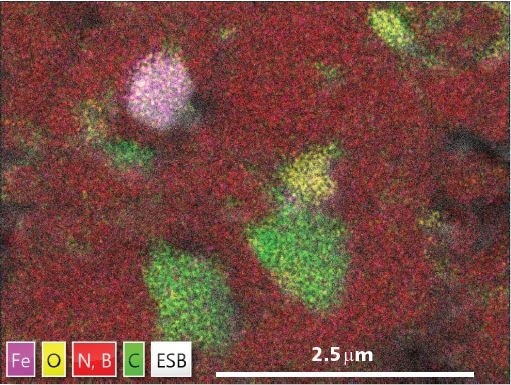

Figure 2. Layered X-ray map on ESB image showing oxide (yellow) and carbon (green) particles on BN substrate (red). 6 minute map acquisition, 1.5 kV, 3,500 cps.

The X-ray image took 6 minutes to create at a rate of 3,500 cps. The data in the image shows that there are two types of particles in the region of interest. The majority of particles (yellow) are composed of mostly oxygen, with the other particles (green) being carbon-based.

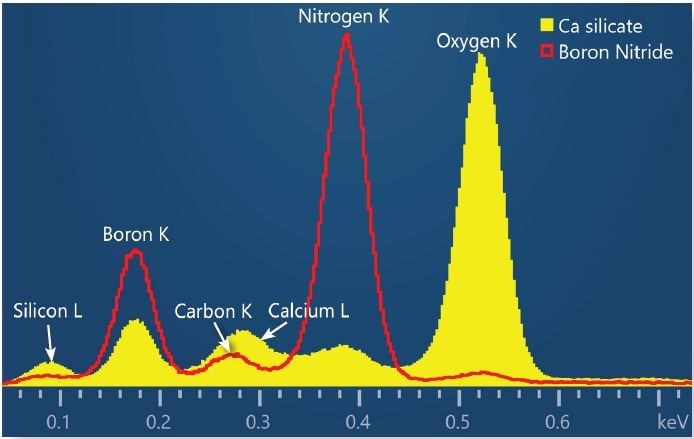

Figure 3 shows X-ray spectra gathered from the ceramic substrate and one of the oxygen-rich particles. The spectra confirm that the sample consists of boron nitride with fine low energy L-lines from Si and Ca and a small B and N contribution.

Figure 3. X- spectra collected at 1.5 kV from boron nitride substrate (red) and an oxide particle (yellow). The particle spectrum highlights the presence of Silicon and Calcium from the detection of low energy L line X-rays from these elements.

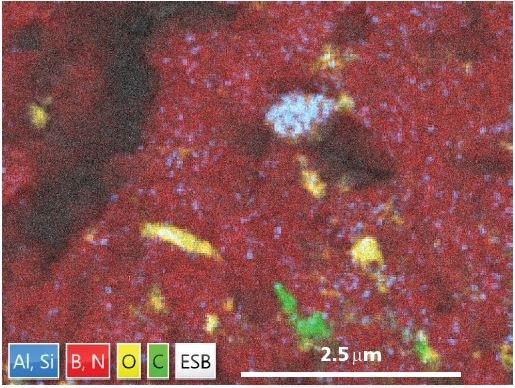

Figure 4. Layered X-ray map image showing the presence of an Al-Si oxide particle (blue). Map collected in 4 mins, at 1.5 kV, 3000 cps.

Figure 5. Layered X-ray map image showing the presence of an Fe-oxide particle (magenta). Map collected in 7 mins, at 1.5 kV, 800 cps.

Conclusion

The imaging of the surface of highly insulating ceramics such as BN is possible using an imaging system with lens backscatter imaging and an extremely low acceleration potential (1.5 kV).

Using the Ultim Extreme EDS detector, which is specially designed to work under these unique conditions, it is possible to chemically characterize different regions in the sample without the need to specially prepare the sample, or to run the experiment under low vacuum conditions.

This information has been sourced, reviewed and adapted from materials provided by Oxford Instruments NanoAnalysis.

For more information on this source, please visit Oxford Instruments NanoAnalysis.