Serial numbers are a frequently used method of tagging and identifying objects that would be otherwise indistinguishable, and are used for everything from firearms to keys, and from passports to bicycles.

As serial numbers are such an effective means of identifying an item they are often purposefully removed from stolen or counterfeit parts, as this makes it harder to trace the item’s origin. The ability of forensics researchers to still determine the serial number from an object where it has been removed is therefore highly useful.

This article will demonstrate how EBSD can be used to observe the plastic deformations introduced during serial number engraving, and how these can be used to determine the serial number following its removal by polishing.

Introduction

Serial numbers can be applied to an object via several different methods. This article will focus on the engraving of serial numbers into a metal surface, a method often used for firearms and keys.

EBSD (electron backscatter diffraction) is a surface analysis method that can be used to differentiate between different crystallographic phases and to determine the size of grains within materials. The techniques ability to ‘see’ different crystalline phases means it can be used to determine where deformation has occurred within a material, meaning it can be used to observe where damage has occurred from the polishing/removal of a serial number.

The technique can be used to reconstruct the original serial number using EBSD band contrast maps.

Sample Preparation

A key had its serial number engraving scratched off so it was no longer legible (Figure 1) by cutting out the region followed by mechanical grinding and polishing with colloidal silica.

Figure 1. A key with an engraved serial number scratched off. The serial number is now illegible.

Method

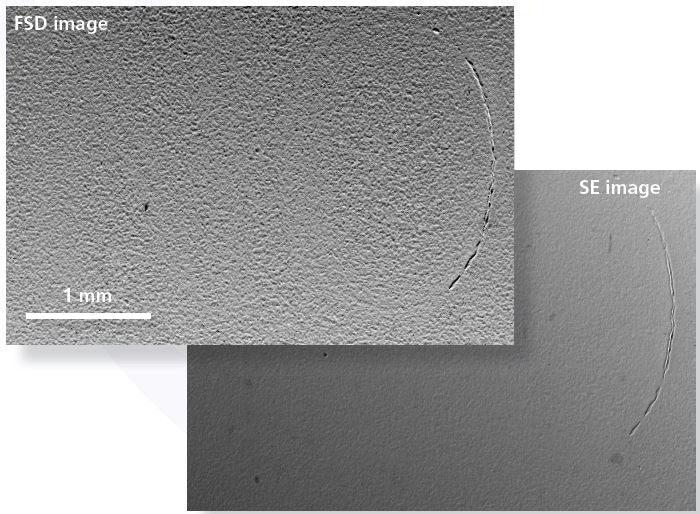

SEM was used to map the region that had contained the serial number using Aztec. An EBSD map, and secondary electron (SE) and forescattered electron (FSD) images were then taken. The resulting electron image (Figure 2) showed that the first section of serial number was only partially removed during the grinding process. Only a small part of the ‘O’ is legible, meaning that some engraved characters were engraved deeper than others.

Figure 2. Forescatter Diode (FSD, upper) and Secondary Electron (SE, lower) images show that only a partially visible letter “O” in the serial number is seen using traditional SEM techniques.

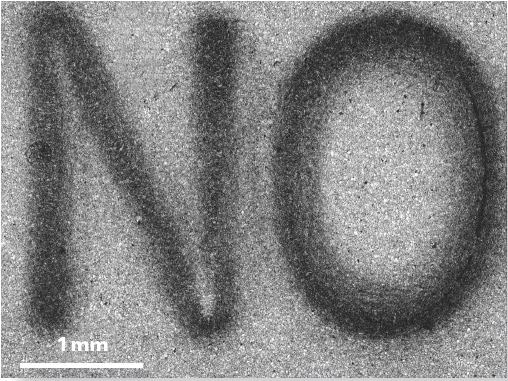

Data from EBSD can be used to study changes in a material’s crystallographic orientations, allowing damaged regions to be identified. A simpler visualization method is to map changes in pattern quality, as in a band contrast map (Figure 3). The band contrast is impacted by a range of factors such as deformation variations, crystal phases and orientations, sample preparation and surface contaminations. Regions that have experienced the greatest deformation have a lower pattern quality and therefore appear darker in the band contrast map.

Figure 3. Band contrast map of same area as the electron images in Fig.1.

Running a band contrast map (Figure 3) allows both letters ‘NO’ to be observed. This is in comparison to the SE and FSD images which only showed ‘O’.

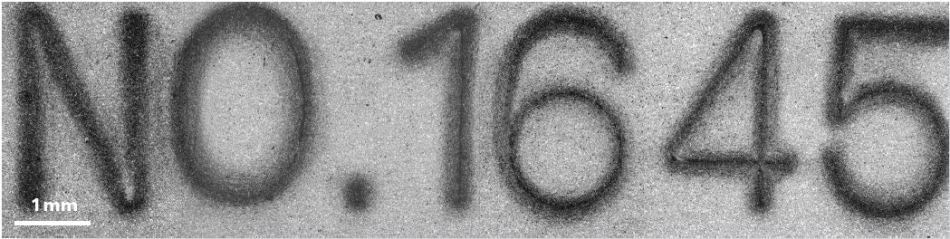

Following confirmation of the method a larger region of the key (13 mm x 3.2 mm) was imaged which allowed the entire serial number to be recovered (NO1645, Figure 4). This imaging method took 10 minutes to carry out with a 8 μm pixel size and a sampling speed of 970 Hz.

Figure 4. Band contrast maps covering the whole serial number.

Conclusion

EBSD has been demonstrated to recover engraved and then removed serial numbers on crystalline substrates as it allows the deformation layer below the serial number to be observed.

This method is rapid and can be used in forensics serial number recovery involving high-importance items such as firearms and keys.

This information has been sourced, reviewed and adapted from materials provided by Oxford Instruments NanoAnalysis.

For more information on this source, please visit Oxford Instruments NanoAnalysis.