Ellipsometry Porosimetry (EP) measures the thickness of the materials and change of the optical properties throughout adsorption and desorption of a volatile specie either under reduced pressure depending on the application (EP) or at atmospheric pressure (EPA).

The EP technique is unique because of its capacity to measure porosity of extremely thin films down to 10 nm, its speeds of measurement and reproducibility. When compared to a traditional Porosimeter, Ellipsometer porosimeters are well matched for extremely thin film pore size and pore size distribution measurement.

In Silicon based technology utilizing low k materials, organic industry (encapsulated OLED\'s) as well as in the coating industry utilizing SolGel technics, film porosity is a crucial factor. Ellipsometry porosimetry (EP) technology is licensed exclusively to Semilab and was patented by IMEC.

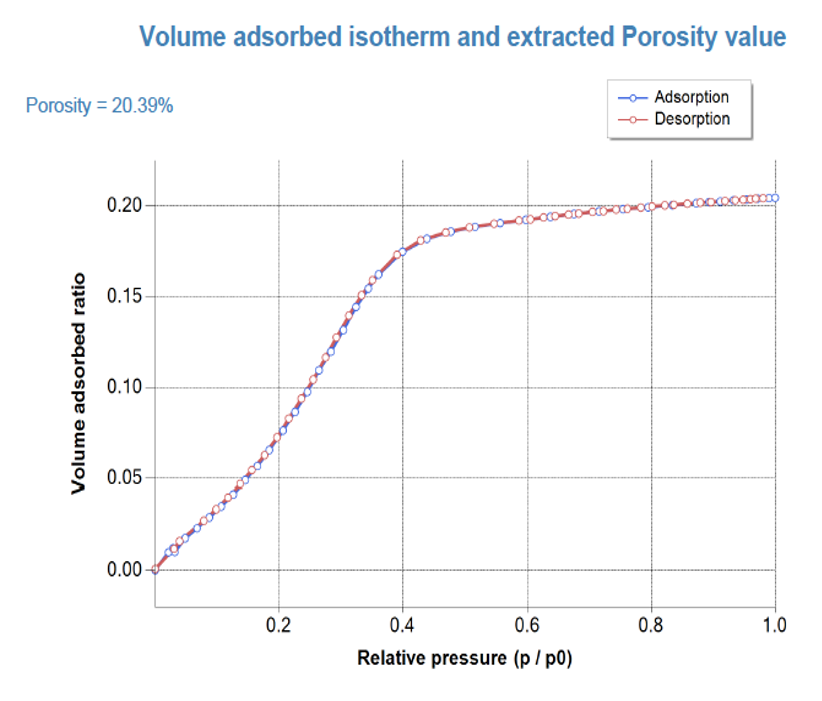

During an adsorption cycle of an organic solvent, Ellipsometric Porosimetry (EP) measures the changes in optical properties and thickness of porous thin films by spectroscopic ellipsometry (SE). As the pores in the material are being filled by the adsorptive these changes happen.

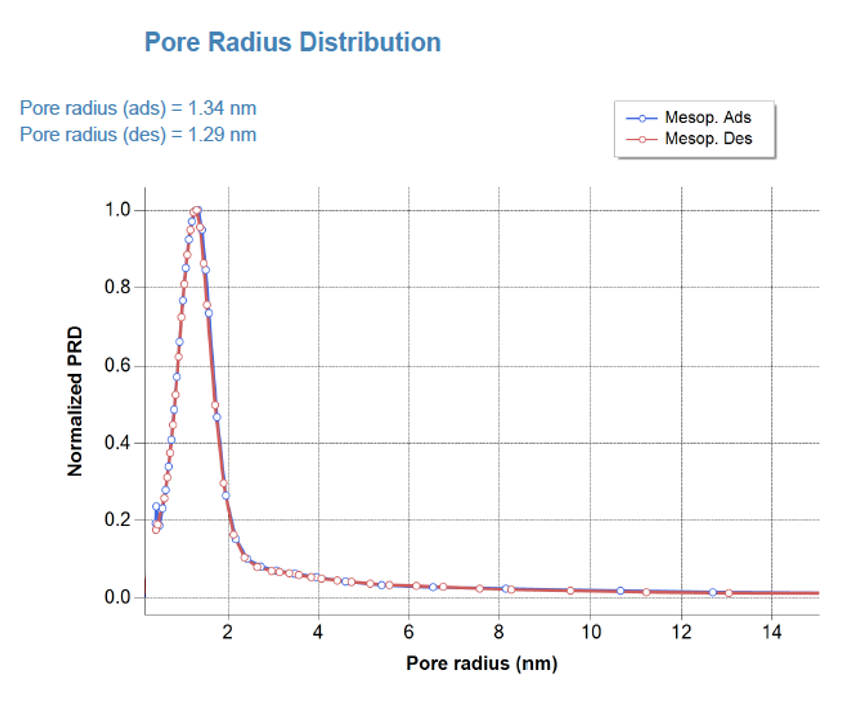

From the measured refractive index and thickness behavior throughout the adsorption cycle, certain layer properties can be deduced:

- Hydrophobicity (water penetration)

- Young’s Modulus

- Porosity

- Pore size distribution and characteristic pore size

- Diffusion coefficient

Semilab proposes two types of adsorption cycle setup:

- At atmospheric pressure, (EPA) with water as solvent

- Under vacuum (EP) with many different organic adsorptive (Methanol, Ethanol, Toluene, IPA, Water, etc.).

The technique can access both meso porosity (2 > Pore diameter > 50 nm) and micro porosity (Pore diameter < 2 nm) and depending on the instrument configuration, can be utilized on layers from 10 nm to several µm.

Compared to a traditional Porosimeter, EP does not need film scratching or sample preparation and is well suited for extremely thin film pore size and pore size distribution measurement. It is a unique technique because of its capability to measure the porosity of both single and multilayered thin film structures, with excellent measurement speed and reproducibility.

Applications

The EP technique has numerous benefits, as thin film porosity is a key factor in silicon-based technology using low k materials or porous silicon films, organic electronic with the permeability of the barrier layer for OPV or OLED (encapsulation), photovoltaic with metal oxides (SiO2, TiO2, W2O3 etc.) for dye-sensitized solar cells, in addition to use in the coating industry using SolGel technique.

Features

The EP technique provides precise and reliable measurements of:

- Pore size distribution and Young modulus of porous thin films such as ultra low K, porous silicon, nanoparticle layers, metal oxides or barrier layers integrity

- Sealing efficiency

- Porosity

- Thickness

- Refractive index

- Diffusion coefficient

This information has been sourced, reviewed and adapted from materials provided by Semilab Semiconductor Physics Laboratory.

For more information on this source, please visit Semilab Semiconductor Physics Laboratory.