Announced in 2005, the Thinky Solder Paste Mixer SR-500 is a distinctive mixer for solder paste. Taking the refrigerated container of solder paste and then setting it in Thinky Solder Paste Mixer SR-500, users can push the start button. Then, within just a few minutes, the machine will optimize the state of the solder paste.

The Start of the Story: Solder Paste Used in Thinky Products

At the start of the 1990s, Thinky sold and manufactured measuring instruments as well as mixers for alginic acid. Solder paste (cream solder) is a material Thinky is familiar with due to the fact it has been used extensively for SMT (surface mounting technology) boards, which constitute the make-up of measuring instruments.

Solder paste is a very delicate material because it is sensitive to changes in temperature and is subject to rapid oxidization at high temperatures. Therefore, it is typically sold frozen and requires refrigeration until it is ready for use. When solder paste has just been removed from the refrigerator, it is usually cold and hard. It must then be brought up to room temperature so it can be put to use, a process that takes around two hours. Previously, a worker was assigned to arrive at work two hours early to remove the solder paste out of the refrigerator - you could call this a process bottleneck.

One day, an employee placed the solder paste into the company's mixer for alginic acid, attempting to mix it. Suddenly, a process that had usually taken more than two hours was completed in just a few minutes. There was a shared recognition that this could be of practical use, and so began the development of mixers for solder paste.

During this time, Thinky was transitioning from the use of leaded solder to the more expensive lead-free solder as environmental concerns were being addressed. This led to the discovery that similar results could also be obtained in a short time for the lead-free solder. This changed the preconceptions of the industry that two hours are required before kneading, which was very well received at exhibitions. Therefore, at Thinky, this put an end to the need for a designated worker to arrive two hours early to bring the solder paste up to room temperature.

Relationship Between SMT and Solder Paste

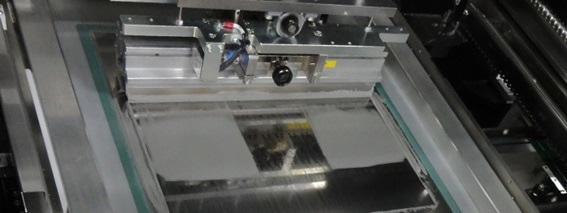

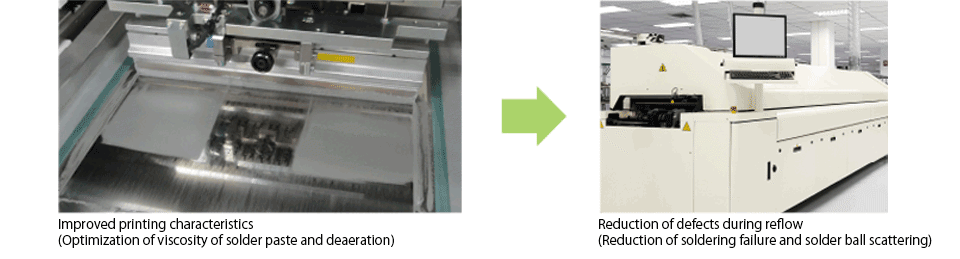

The printing process is the most important and difficult part of the SMT process. Printing low-quality solder paste immediately leads to the board failing. The control of temperature, stirring and deaeration, as well as viscosity of solder paste, are decisive and important factors in reducing defects in the SMT process.

Temperature Control and Condensation

Solder paste is a combination of solder and flux, which is usually stored in a refrigerator to eliminate a chemical reaction (mainly oxidation) between the solder and the flux.

Oxidation of the solder paste decreases the activity of the flux, causing decay in the solderability (solder wettability). Therefore, the process of ensuring a normal temperature (room temperature) before use is of utmost importance. If any insufficiencies arise during the process of restoring the paste to room temperature, such as the lid being opened while the solder paste is colder than room temperature, condensation may form on the solder paste. This exposure to moisture may cause scattering of solder balls later in the reflow process.

With the SR-500, solder paste in a commercial container can be immediately processed after being removed from the refrigerator. Therefore, a procedure that previously took about two hours, including bringing the paste to room temperature, can be completed in around ten minutes, which includes the dispersion of the paste. Furthermore, opening the lid of the container is not required during this process, which eliminates any condensation.

Viscosity

Solder paste is a heavy and dense material. This makes hand kneading an arduous and time-consuming task, with differences occurring between individuals that directly affect the finish. Hence, the need for a skilled spatula blender to ensure a consistent quality of the solder paste when mixing by hand.

With its powerful and controlled stirring, the SR-500 makes it straightforward for anyone to duplicate the requisite conditions for solder paste. Stabilizing the condition of the solder paste achieves standardization of the printing of circuit boards.

When refrigerated for several weeks, the viscosity of the solder paste inside a container may become variable. This is because over time solder particles with high specific gravity drop to the bottom of the container. Therefore, the solder paste should be thoroughly stirred from the top to the bottom of the container so that the paste viscosity is consistent when being used. The Thinky Mixer is most suitable for this process because of its ability to mix highly viscous material stably and consistently.

Problems such as missing solder, solder wetting, and solder sagging are often down to the viscosity of the solder paste, making this an important factor to control. Deficiencies such as missing solder and solder wetting can cause chipping (Manhattan phenomenon) and contact failure. When screen printing, if there is an increase of viscosity in the solder paste, part of the paste may stick to the metal mask (printing plate) or ‘horns’ may appear on the solder printed on the board. If the viscosity is too low, distortions such as sagging in the shape are likely to occur after printing.

By using the SR-500 to mix and stir the solder paste uniformly, squeegee movement becomes smooth, reducing the risk of clogging the metal mask.

Stirring and Deaeration

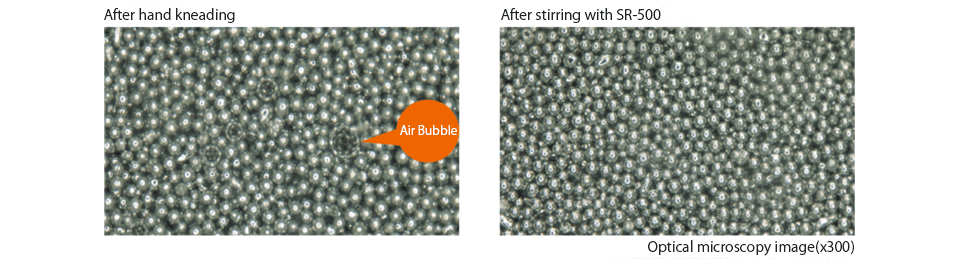

The formation of solder balls and bridge failure is often caused by an excess of moisture and air bubbles in the solder paste. The stirring technology of the SR-500 eliminates bubbles and voids that cause solder balls. Combined with the prevention of condensation and the absence of any excess moisture, the deaeration of the solder paste while stirring leads to a reduction in bridge failure.

Therefore, because of the effect of centrifugal force due to the revolution by Thinky’s Mixer SR-500, light air bubbles move upwards and deaeration occurs. Heavy material is simultaneously drawn to the bottom of the container, averting the adhesion of solder paste onto the inside surface of the lid. Subsequently, this also prevents any loss of paste.

Evolution of SR-500 as a Machine Dedicated to Solder Paste

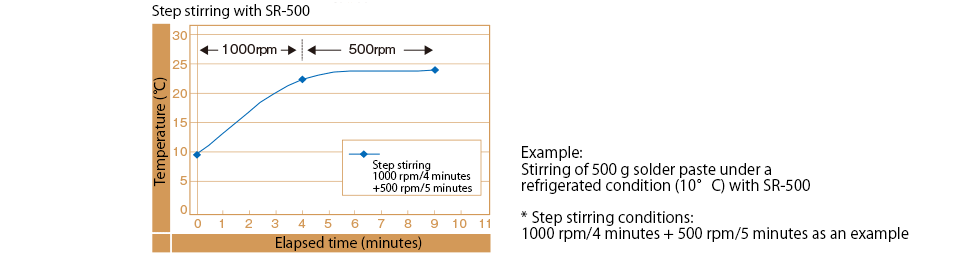

The SR-500’s predecessor had the issue that the temperature of the paste increased with continuous high-speed stirring. The latest SR-500 model performs stirring in two steps to prevent the solder paste from increasing above the normal temperature. To achieve this, the first step sees the temperature increased by high-speed rotation and then the dispersion is maintained by low-speed rotation, keeping the paste at room temperature.

Furthermore, the user has the option to amend the rotation speed as well as set the operation time on a second-by-second basis, as influenced by the type and conditions of solder paste. Thinky’s SR-500 also has a memory function that conveniently allows the user to record frequently used recipes.

For Higher Work Efficiency, Higher Reproducibility and Standardization

The innovation of Thinky’s Solder Paste Mixer SR-500 was the result of a chance trial carried out for fun, but it has become a product that has provided various solutions concerning the problems of solder paste.

The importance of managing the quality of solder paste is expected to increase in the future due to the leaning trend toward the miniaturization of chips and other products in the surface mounting industry.

As previously mentioned, in the hand kneading of solder paste, the adjustment of viscosity and dispersion is inefficient and requires a high level of technical skill. Also, the differences from one skilled technician to another may significantly affect the product quality. Almost anyone can easily prepare solder paste in just ten minutes by simply taking a container of solder paste out from the refrigerator, placing it in an SR-500, and then pressing a button. The SR-500 can rise to the challenge of the sudden increased need for extra solder and has outstanding reproducibility of the quality.

The reputation of the SR-500 is one of few failures. Many customers have been using it over a decade. We hope that the SR-500 will experience continued usage by those facing problems concerning solder paste and involved in the evolution of mounting technology.

Feel free to request a trial use of SR-500 if you are interested in reducing the labor-intensive process of hand kneading as well as eliminating the need for a worker to come in early.

→ View product information

→ Watch video

Optional Items

● Adapters for Containers of Various Solder Manufacturers

Made in Japan, the adapter 250AD-201 is supplied for a standard container of 500 g solder paste. Compatible adapters for containers made by other manufacturers are also available. (Contact us for special orders.)

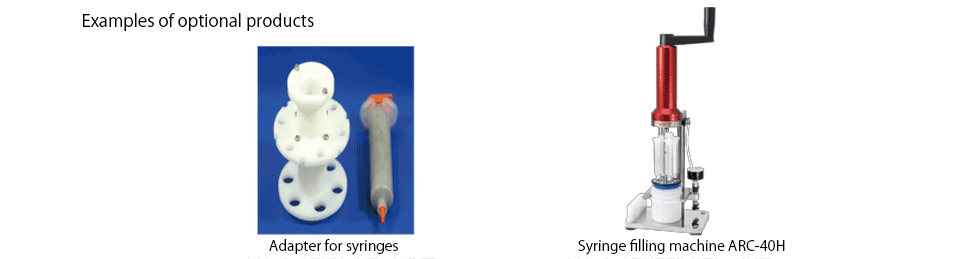

● Adapter for Syringes

The optional syringe adapter allows commercially available syringes to be attached directly to the SR-500 which facilitates rapid re-dispersion and deaeration. Air leakage (blank firing) can be prevented by using a syringe after deaeration. In addition to solder paste, the adapter may also be used for deaeration chip bond.

● ARC-40H (manual syringe filling machine)

Materials such as solder paste and chip bond, mixed using SR-500 or other Thinky mixers, can be loaded into syringes by the customer. Up to four syringes can be loaded simultaneously.

● Multiple Sensor (SR-500 will be supported in the future)

Precise temperature control is manageable because the temperature of the material in the mixer can be monitored in real-time during stirring.

This information has been sourced, reviewed and adapted from materials provided by Thinky Corporation.

For more information on this source, please visit Thinky Corporation.