To regulate and to optimize processing methods, granular materials and fine powders must be precisely characterized for industrial applications. These methods relate to granulometry, morphology, chemical composition (i.e. the properties of grains) and to flowability, density, blend stability, and electrostatic properties (the behavior of bulk powder). Unfortunately, most research and development (R&D) techniques for the latter behavior method are archaic.

Measurement processes have been automatized in our efforts to update these techniques over the last ten years, thereby meeting current requirements of R&D laboratories and production departments. We have also developed rigorous initialization methods to obtain reproducible and interpretable results.

A variety of measurement methods have been tested and established to suit the needs of granular materials and industry processing powders. It is known that image analysis techniques allow for the improvement of measurement precision. However, here we will focus our investigation on the GranuPack and GranuCharge instruments.

GranuPack

Widely known as the “tap-tap test”, the Hausner ratio, as well as the bulk density and the tapped density measurements (commonly referred to as the “tap-tap test”) are quite popular for powder characterization due to the simplicity and swiftness of the measurement.

The important parameters for transportation, storage, caking and so on include the density and ability of a powder to increase its density. Although the recommended procedure is defined in the pharmacopeia, this simple test has three major drawbacks.

Firstly, the filling method influences the initial powder volume and the result of the measurement differs depending on the operator. Next, naked eye measurements of the volume can introduce large errors into the results. Lastly, the simple method bypasses the compaction dynamics between the first and the concluding measurements.

The behavior of the powder submitted to successive taps is analyzed with an automatized device, such as the GranuPack instrument, which has improved tapped density measurement methods based on research findings. A dynamical parameter, n1/2, and an extrapolation of the maximum density, ρ(∞), are extracted from the compaction curves. The Hausner ratio, Hr, initial density, ρ(0), and the final density after n taps, ρ(n), are meticulously measured and the tap number is commonly fixed at n = 500.

Other such indexes can be utilized. However, they are not in this report. With a rigorous automated initialization process, the powder is positioned in a metallic tube. After this, a light hollow cylinder is put on the top of the powder bed to keep the powder/air interface flat during compaction. Subsequently, the tube containing the powder sample rose up to a fixed height of ΔZ and performed free falls at a height generally fixed to ΔZ = 1 mm or ΔZ = 3 mm.

After each tap, the height, h, of the powder bed is automatically measured and from this the volume, V, of the pile is calculated. The density is calculated as the ratio between the mass, m, and the powder bed volume, V. As the powder mass, m, is known, the density, ρ, is assessed and plotted also.

The Hausner ratio, Hr, relates to the compaction ratio and is therefore calculated by Hr = ρ(500) / ρ(0) , where ρ(0) is the initial bulk density and ρ(500) is the tapped density computed obtained after 500 taps. Results are reproducible with a small quantity of powder (typically 35 ml) with the GranuPack method.

GranuCharge

The triboelectric effect takes place at the contact between the grains and at the contact between the grains and the device during the flow of powder inside a device such as a mixer or silo. Electrostatic charges are generated inside a powder during a flow, causing electric charges due to the aforementioned triboelectric effect, which is a charge exchange at the contact between two solids. Consequently, important parameters include the characteristics of the powder and the nature of the material used to construct the device.

The GranuCharge instrument automatically and precisely measures the quantity of electrostatic charges created within a powder during a flow in contact with a selected material. To obtain reproducible results, a rotating or a vibrating device is used to feed the V-tube regularly. The powder sample flows inside a vibrating V-tube and falls into a Faraday cup connected to an electrometer. The electrometer measures the acquired charge by the powder during the flow.

Selected Powders

The five standard powders selected for the selective laser sintering (SLS) and the selective laser melting (SLM) processes in this study are as follows:

- One virgin and one recycled Duraform PA12 (DFPA) powder (Polyamide 12).

- One steel Carpenter (1.4404) powder and the one LPW steel (1.4404).

- Arkema Orgasol Invent Smooth (Polyamide 12).

The SLS process is based on polymeric powders and the SLM process is based on metal powder.

The Duraform polyamide 12 is investigated in both forms. The recycling step is required to guarantee a good quality of the built parts due to the post-condensation mechanism. This leads to an increase in molecular weight of the unused polyamide 12 powder. In SLS, reactive end-groups of the polyamide 12 interact with each other to increase molecular chain length and the viscosity of the melt as the powder bed is heated up just below the melting temperature of the polymer.

Due to its chains’ ends being capped, this behavior is not observed with the Orgasol Invent Smooth polymide, produced by Arkema. Both metal powders are based on the conventional 1.4404 stainless steel (316L).

Polyamide 12 Powders

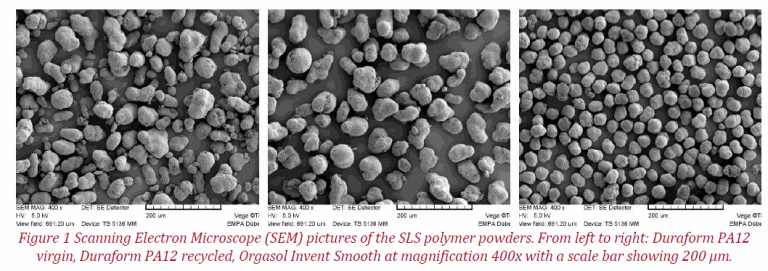

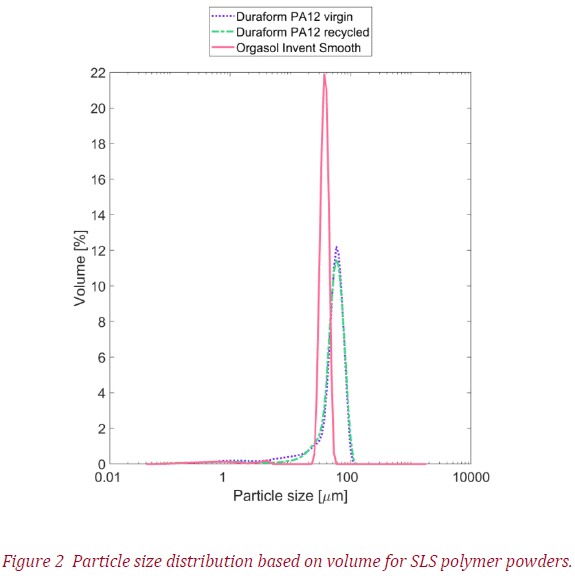

Providing a good overview of the powders’ extrinsic properties, scanning electron microscope (SEM) pictures of the SLS polymeric powders can be seen in figure 1. The DFPA powders are quite potato-shaped, coarse and present disparate sizes. On the other hand, the Orgasol is more spherical, particles are smaller and present an almost identical size. These visual observations correlate with the analytical investigations presented below for the particle size distribution (PSD) performed by laser diffraction on a Beckman-Coulter LS230.

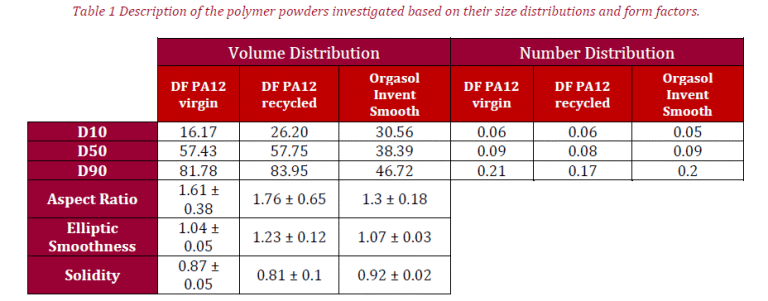

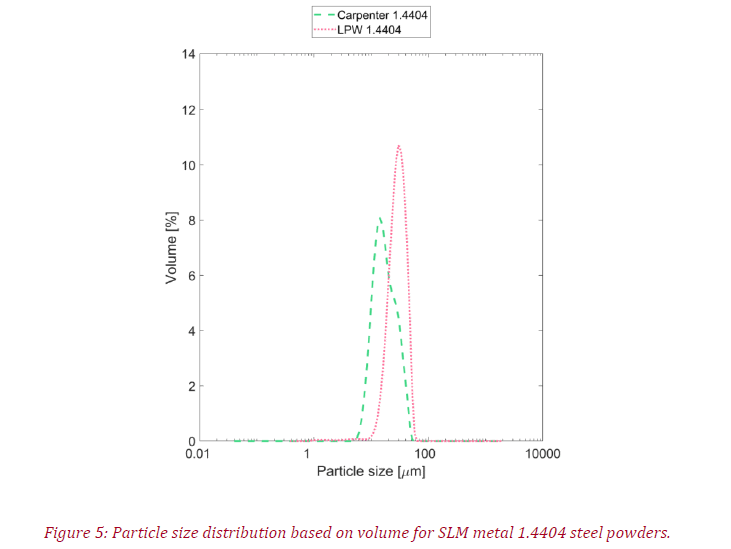

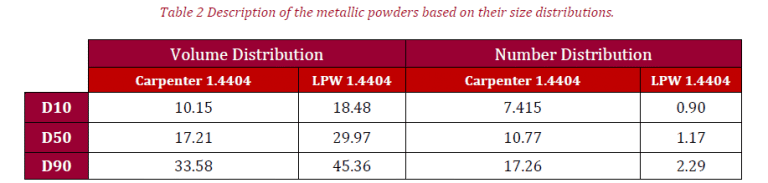

The Orgasol Invent Smooth displays a strongly mono-modal distribution while both DFPA powders are wider, notably in the range 1 to 30 μm. It is a bimodal distribution of both fine and coarse particles with a potato shape. Figure 2 shows the PSD of both polymer (left) and metal powders (right). The difference in size is observed in Table 1 where the volume and number distribution are shown. The number distributions for all materials are strongly skewed to the right because the fine particles weigh 1:1 with the coarse, while they only weigh 1000:1 for volume distribution. For the metal powders in Table 2, it is important to note that the amount of fine particles in the Carpenter 1.4404 powder is reduced to a minimum compared to the LPW and the polymer powders as well. The Carpenter powder also presents a PSD which is significantly lower than the LPW, however, both powders present a broad distribution.

The elliptic smoothness implies the roughness of the particle’s surface and it is computed as the ratio between the particle perimeter and its fitted ellipse. The form factors in Table 1 were deemed as useful in predicting the flowing behavior of SLS powders. The aspect ratio (AR) is the ratio between the major to minor axes of the fitted ellipse around the particle.

Solidity quantifies the “compactness” of the particle by the ratio between the particle’s area to the convex area surrounding it. The Orgasol powders are compact and spherical, high solidity and low aspect ratio, while the DFPA are more elongated and convoluted, thus having a higher AR and a slightly lower solidity, confirming the finding in figure 1. Powders that are spherical and smooth will be more likely to flow homogeneously while elongated and rough particles would be obstructed and thus agglomerate.

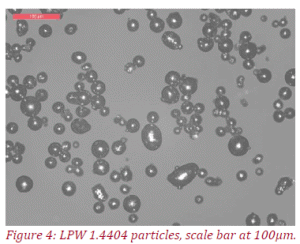

Metallic Powders

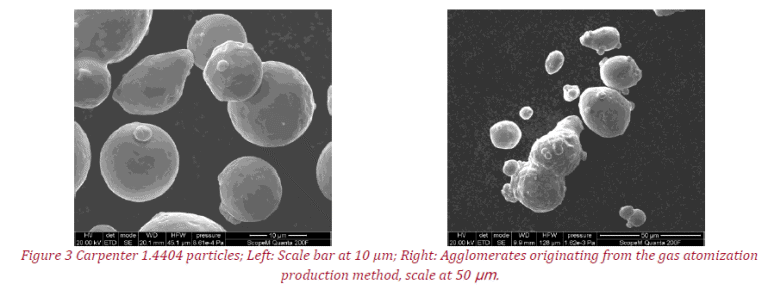

Due to the production method of gas atomization of molten metal, some particles are welded together and present elongated shapes such as in the right picture in figure 3. The Carpenter steel particles shown here display spherical shapes as well as a smooth surface and the fine particles are likely to stick to coarser ones. The form factors for the metal powders are not provided but it is expected that values are similar to the Orgasol powder, i.e. high solidity, low aspect ratio and low elliptic smoothness.

Discussion

The five powders presented above, although different in molecular structure and size distribution, are of interest as they all perform well in their respective processes. As it impacts directly on the final density of the part produced and subsequently its mechanical properties, the packing behavior of powders for the SLS and SLM processes is vital.

The investigation of the packing behavior using the Granupack should allow a deeper understanding of how these powders behave under stress and could unravel the complex relationships between size, form and compaction behavior. The packing behavior of powder is related to its spreading behavior, which is equally important to ensure a homogeneous powder bed and a consistent interaction with the laser source.

GranuPack Analysis

Experimental Protocol

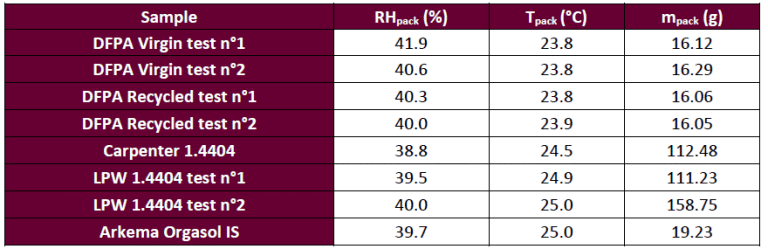

For each GranuPack experiment, 500 taps with a frequency of 1 Hz and the measurement cell free-fall was 1 mm (∝ tap energy) were applied to the sample. Prior to experimentation, air temperature and hygrometry were recorded. The main purpose is to prove the high accuracy of the GranuPack instrument, highlighting the aging of powders and their flowability, therefore some samples were analyzed twice.

Experimental Data

Powders bulk densities were analyzed under the same moisture conditions (approximately 40% RH and 24 °C) and the powder mass is recorded before every experiment. By following the software instructions, the sample is poured inside the measurement cell (i.e. without user dependency). The following table summarizes the data before the experiment (RHpack, Tpack and mpack are respectively the relative humidity, temperature and powder mass measured before samples are introduced inside the GranuPack).

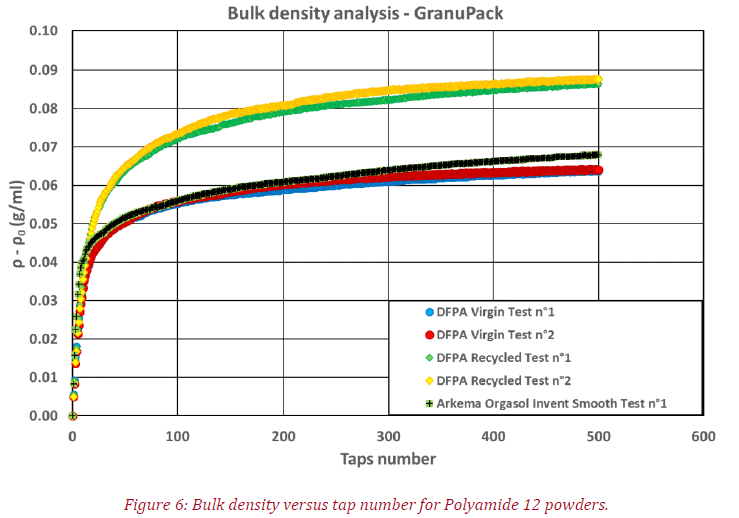

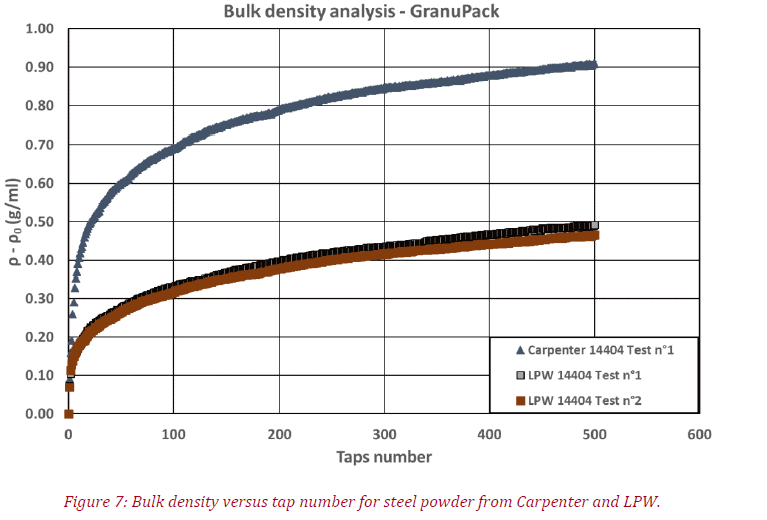

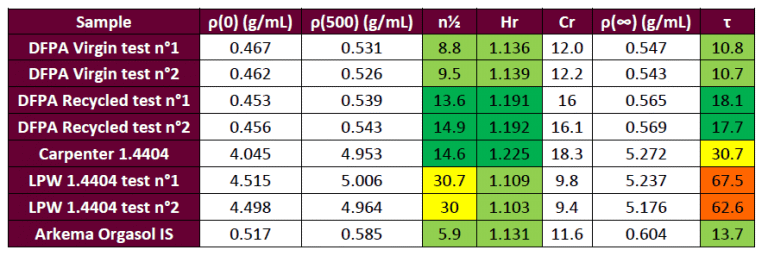

Figures 6 and 7 denote the compaction curves, which are the bulk density variations (ρ(n) – ρ(0)) versus the number of taps, respectively for Polyamide 12 and steel powders. Error bars were displayed but they are too small and bulk density error is close to 0.4%.

Where ρ(0) is the initial bulk density (in g/mL), ρ(500) is the bulk density after 500 taps (g/mL) and ρ(∞) is the optimal bulk density (in g/mL, calculated by a GranuPack software model), whereby the minimum density tapping test can achieved. Full results are described in the following table. Hr and Cr are respectively, the Hausner and Carr ratios. n1/2 and τ are the two parameters linked to the compaction kinetic (see Appendix 1).

Results Interpretation

Comparing DFPA Virgin to the recycled powders, we can see that the virgin powder has a better flowability (with Hausner ratio) and easy compaction (with n1/2 parameter), possibly due to the aspect ratio of the particles. Figure 6, figure 7 and table 4 show that the GranuPack instrument can differentiate between each powder.

Due to the higher contact points between particles for the recycled, compaction kinetics are slower for recycled rather than virgin powder. On the other hand, virgin powder with an AR close to 1.61 is closer to a spherical shape (AR = 1.76). The confirmation comes from the solidity of those particles, close to 0.87 for virgin powder and to 0.81 for recycled, which means that the amount of “void” around recycled polyamide 12 will be larger than the virgin.

With GranuPack analysis, we see that the flowability of LPW powder is better than the Carpenter steel. Confirmed by the Hausner ratio (1.131) and n1/2 parameter (5.9), the flowability and compaction kinetics of the Arkema Orgasol Invented smooth is respectively good and fast due to the powder solidity close to 1 (0.91). Considering the sample size, a possible justification is the particle size distribution, smaller particle size and flowability, with D50 = 17.21 μm for Carpenter and D50 = 29.97 μm for LPW.

GranuCharge Analysis

Experimental Protocol

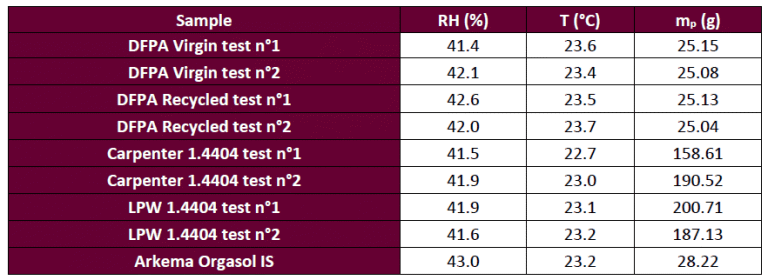

Tests have been twice repeated to show GranuCharge accuracy/reproducibility (except for Arkema Orgasol Invent Smooth Powder). The Granucharge instrument examined the triboelectric effect of the powders and for each experiment, stainless-steel 316L pipes and a rotating feeder were used (see figure 8). The powder was not recycled after a measurement and the quantity of product used for each measure was approximately 50 mL (exact values are shown in the next table).

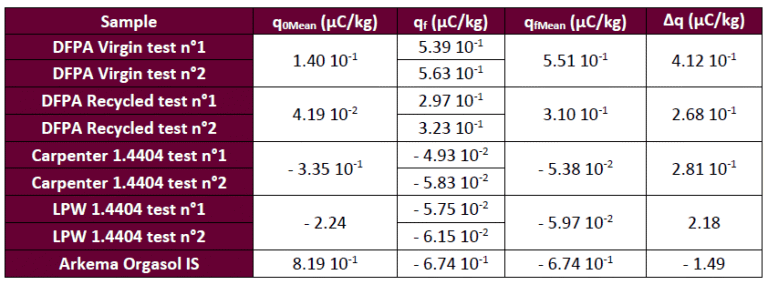

At the start of the test, the initial powder charge (Qi, in μC) is measured by introducing powder inside the Faraday cup twice, with the average value shown in Table 6. Before experimentation, powder mass (mp, in g), air relative humidity (RH, %) and temperature (°C) are noted. After this, the powder is poured inside the rotating feeder, then the experiment begins. The final charge is measured at the end (Qf, μC). The next table summarizes the raw results obtained.

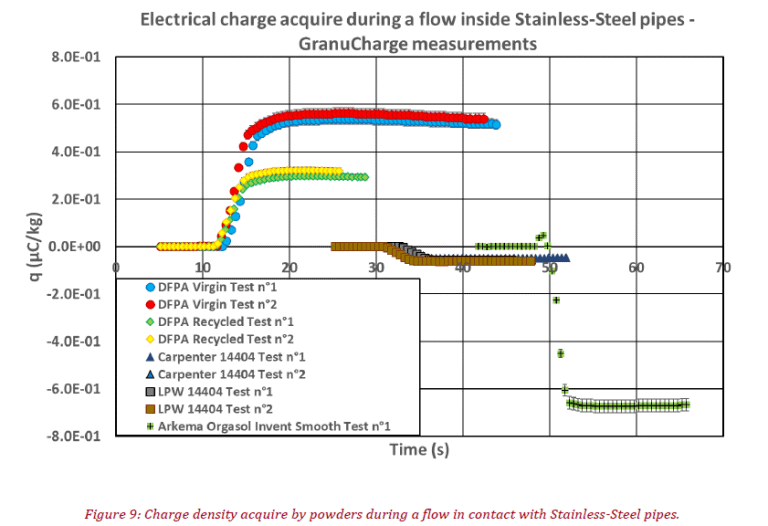

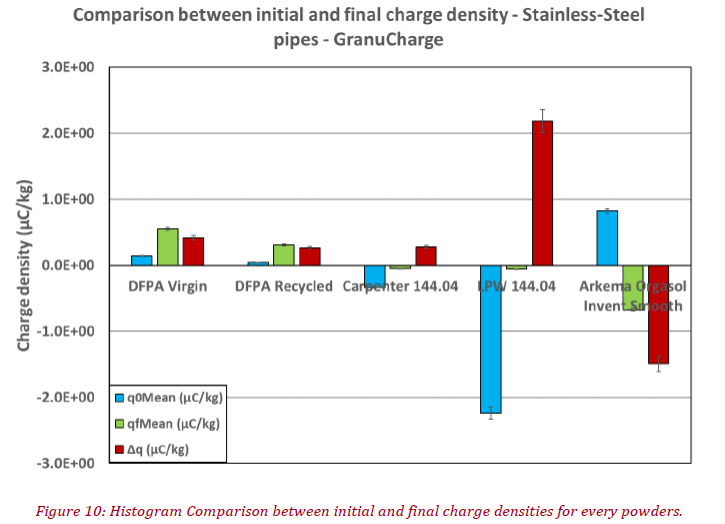

Each charge density value corresponds to the average value calculated with the reproducibility tests (Δ?=??????− ?0????, in μC/kg). Table 6 summarizes all the results obtained with the GranuCharge instrument whereas figure 9 represents the electrical charge density obtained by each powder during a flow contacting stainless steel.

Results Interpretation

LPW has the highest initial charge, next is the Arkema Orgasol Invent Smooth, with Carpenter in the third position while DFPA virgin and recycled have similar values and a slightly lower charge density for the recycled type. With the GranuCharge instrument, the differentiation between powders can be accurately made, even with initial charge densities, which are quite different.

Because it will acquire negative charge during the flow, Arkema Orgasol Invent Smooth has an opposite behavior. After a flow, LPW steel is slowly discharged and once this value reaches 0 the powder will acquire positive charges on contact with the stainless steel pipes. After a flow inside the stainless steel tubes, the electrical charges for DFPA virgin powder is higher than the recycled.

Due to powder flowability, the same behavior is highlighted when comparing LPW to Carpenter steel, which is higher for virgin and LPW than recycled and Carpenter powders. Arkema’s polyamide 12 provided is negatively charged at the end of experiment, while DFPA obtains a positive charge. This could be due to differences between particles coating, but a further assessment must be carried out to prove this assumption.

Conclusions

The sensitivity of the GranuPack shows differences between virgin and recycled versions of the same powder. However, triboelectric effect must be studied with the GranuCharge instrument, which is sensitive to oxidation, pollution, rugosity and other surface states, to see a clearer difference in particle aspect ratio and solidity. Despite the aging of powder being difficult to explore with classical methods, GranuCharge experimentation shows great accuracy and reproducibility, showing aging well.

References and Further Reading

- Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

- Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

- Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

- Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

- Compaction Dynamics ofWet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

- Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

- Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

- Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

- Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

- Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

- How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

- Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

- Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

- Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

- Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

- Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

- Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

- Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

- The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).

This information has been sourced, reviewed and adapted from materials provided by Granutools.

For more information on this source, please visit Granutools.