A planetary centrifugal mixer is a device for mixing and degassing materials simultaneously without the use of agitator blades.

What is the Difference Between an Atmospheric and a Vacuum Planetary Centrifugal Mixer?

The two varieties of planetary centrifugal mixers are called atmospheric-pressure type and vacuum type. Bubbles often cause difficulties during the mixing process, and, in such cases, one of these mixers can be used depending on the individual situation. The atmospheric-pressure type mixer removes air bubbles visible to the naked eye of several hundred microns order.

The vacuum type mixer is used for the removal of invisible micron-sized bubbles. Traditionally, deaeration is accomplished with a desiccator once mixing has taken place. Carrying out this process is time-consuming. However, the planetary centrifugal mixer enables deaeration while mixing without any overflow, which reduces the length of time it takes.

How to Mix Materials with Low Viscosity

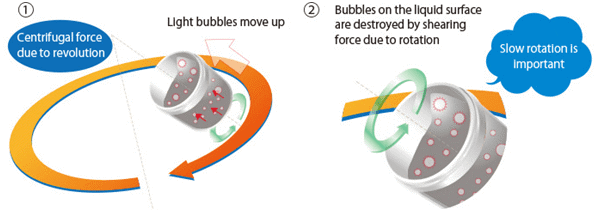

Deaeration by atmospheric pressure type planetary centrifugal mixer is suitable for materials with relatively low viscosity. A “deaeration mode” is present on the majority of atmospheric-pressure type mixers, and by altering the balance between revolution speed and rotation speed, deaeration can be achieved when based on these two principles:

- That light bubbles are forced to the surface of the liquid by the centrifugal force caused by the revolution

- That bubbles rising to the liquid surface are destroyed by shearing force when slow rotation that doesn’t engulf any bubbles (for instance in deaeration mode) is used

How are High Viscosity Materials Mixed Without Agitator Blades?

The planetary centrifugal mixer does not need mixing blades to mix materials and deaerate materials at the same time.

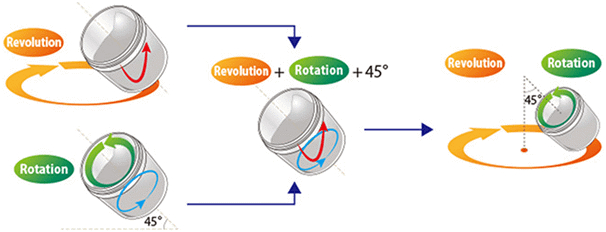

To achieve this, there are three key factors to consider.

- Revolution. This uses centrifugal forces to move the material away from the center.

- Rotation. Rotation and shearing are achieved by rotating the container and causing material flow.

- 45-degree rotation. By tilting the axis of rotation to a 45-degree angle causes three-dimensional flow.

Additionally, the flow velocity (direction) changes rapidly between the liquid surface and the container wall, resulting in complex flow and a strong shearing force. In particular, the strong shearing force causes droplets and particles to become smaller and enhances their dispersibility. Air bubbles are also finely dispersed during this process.

Because of this, it is possible to mix even high-viscosity materials uniformly, even in a short time frame without the use of mixing blades.

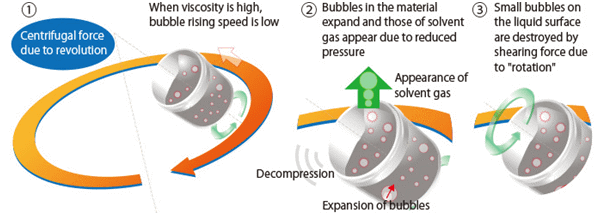

Defoaming occurs based on the three principles below:

- The rising speed of bubbles is low when viscosity is high, with bubbles being carried to the surface by convection of the material.

- Reduced pressure causes bubbles to expand and be destroyed. Solvent gas bubbles are also produced.

- Due to rotation, small bubbles on the liquid surface are also destroyed by shearing.

Thinky’s Non-Vacuum Planetary Centrifugal Mixer

THINKY Corporation has introduced a planetary centrifugal mixer called “THINKY MIXER” ARE-310.The product is the standard model of the THINKY MIXER series.

High-viscosity materials can be simultaneously mixed, dispersed, and deaerated with this mixer. It has a deaeration mode enabling high-precision deaeration. The new model establishes superior performance in the deaeration of high-viscosity materials and adhesives where viscosities have been increased by added fillers.

This information has been sourced, reviewed and adapted from materials provided by Thinky Corporation.

For more information on this source, please visit Thinky Corporation.