In this interview, Dave Wolff from Nel Hydrogen talks to AZoM about the role of hydrogen generation for Thermal Processing.

What are thermal processing atmospheres?

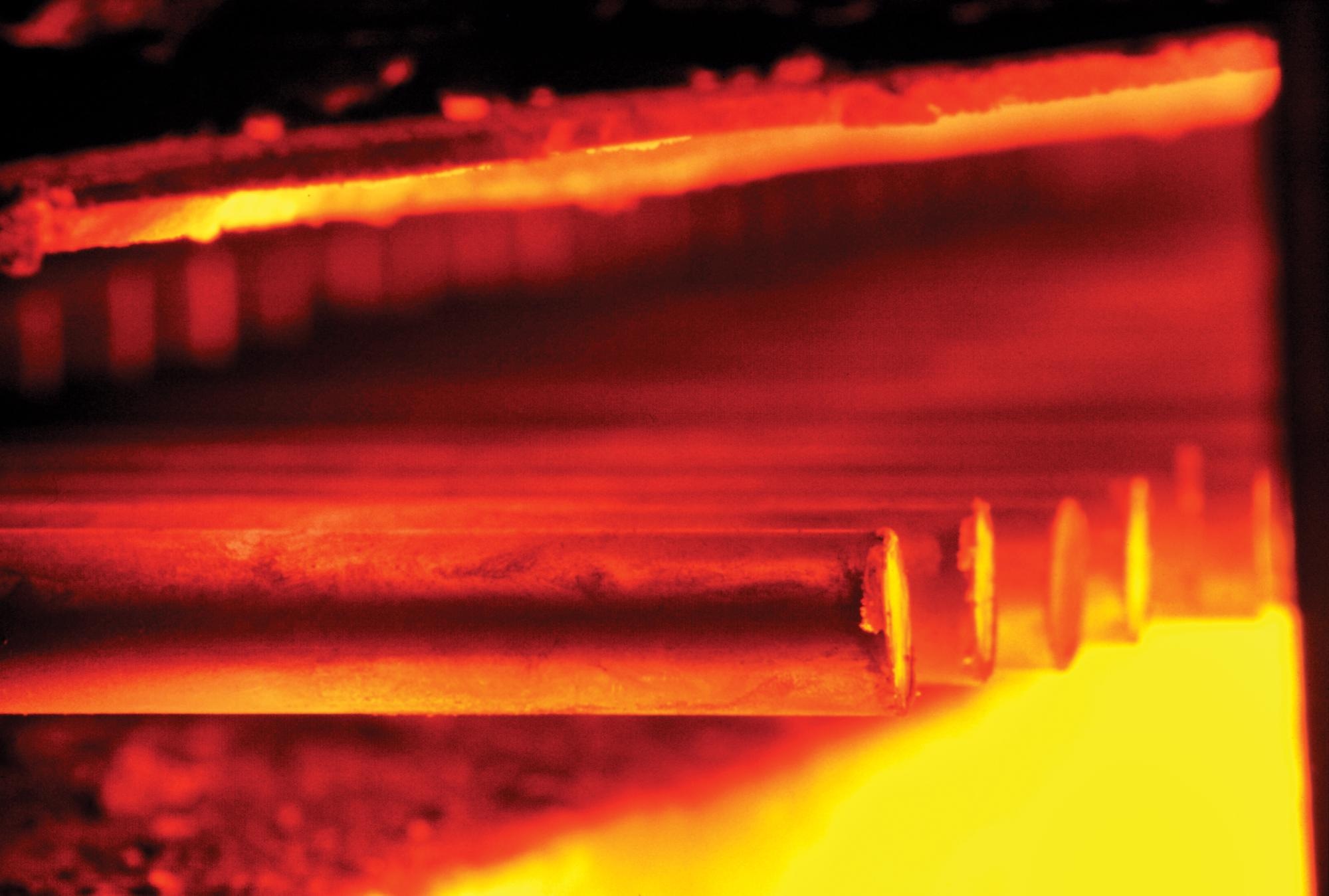

Fabricated metal products are often processed at various stages in fabrication at high temperatures to change their properties to match the needs of the intended application. Examples of high-temperature processing include annealing, sintering, and brazing. Because high temperature intensifies the oxidation caused by atmospheric oxygen that can lead to oxidation damage of the metal product, the metal must be protected from atmospheric oxygen (and from oxygen that might be liberated from surface oxides at temperature). Atmospheres containing hydrogen are the oldest and most frequently employed technique for protecting metal parts at high temperatures. Hydrogen reacts with molecular oxygen and makes it non-reactive with the metal, thereby protecting the metal. Certain parts are processed in a vacuum atmosphere, often because they are incompatible with hydrogen.

Which manufacturing processes use thermal processing atmospheres?

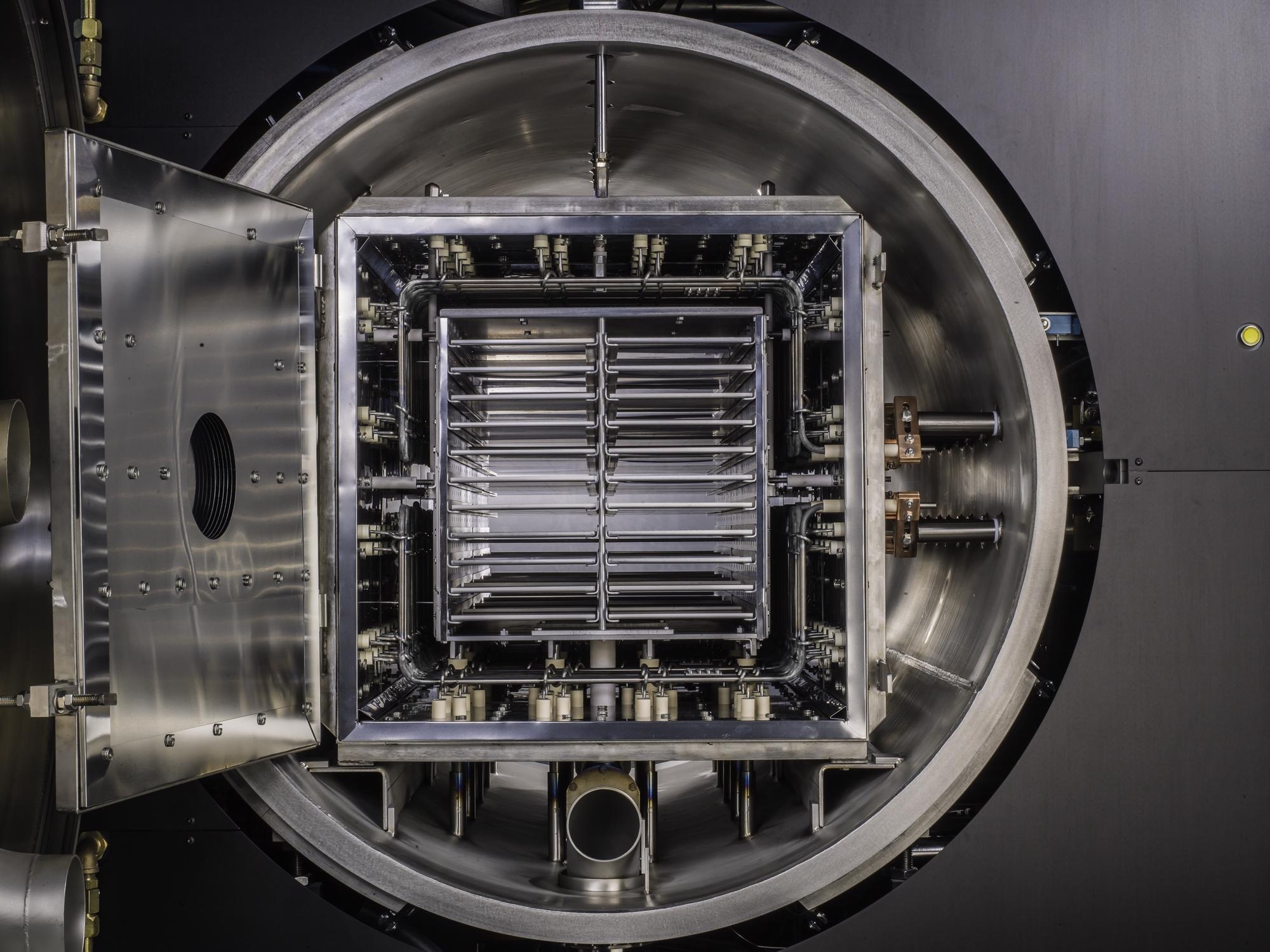

Hydrogen atmospheres are used in hydrogen-compatible furnaces for many operations such as annealing, sintering, and brazing. Annealing might be used in a rolling mill, or a wire mill, or a tube mill, any time that work is done on a continuous strand that must be then softened so the next stage of processing can be performed. Annealing softens metal, returning toughness to metal that has been embrittled by being work-hardened. Sintering has been used for powdered metals for decades, first for press-and-sinter (P/M), then for Metal Injection Molding (MIM), and most recently for sintering of Additively Manufactured (AM) parts using a binder jet type of process. In some cases, particularly for MIM and AM parts, the furnace employed might be a vacuum furnace that uses a partial-pressure stream of hydrogen backfill to clean the parts and prevent oxidation which is critical because of the high surface area of the powdered metal particles that compose the parts. Brazing is widely employed for joining two or more parts into a high strength assembly, often creating subassemblies that can’t be made in a single fabrication step. In brazing, hydrogen plays a crucial role as a flux in reducing surface oxides to enable the braze material to flow properly and adhere.

How are furnace atmospheres created?

Furnace atmospheres are created either in an atmosphere generator or by mixing pure gases using gas blending equipment. The oldest atmospheres were created in gas generators that provided a blended gas atmosphere such as exothermic or endothermic gas blend, both based on thermally cracked natural gas and dissociated ammonia or based on catalytically cracked ammonia. These generated gas blends are general-purpose atmospheres, usable to provide acceptable results for a wide range of metals thermal processing. Industrial gas providers popularized blended atmospheres that are precisely blended from pure gas constituents to achieve highly precise blended atmospheres in the exact ratios of gas constituents to achieve the best possible process results. Blended atmospheres upped the game in terms of maximizing the quality and performance of thermal processing atmospheres. Most recently, on-site generation of pure hydrogen (and nitrogen) have enabled atmospheres to be custom-blended from generated pure gases – providing the performance benefits of blended atmospheres while entirely eliminating the need to store atmosphere components.

Where do thermal processers source their atmosphere gases?

Atmospheres based on exo and endo generation are made in dedicated generators that process natural gas or propane. Propane is a delivered, stored industrial fuel product. In the case of natural gas, no storage is required, as the raw material is piped to the processor. For dissociated ammonia, the processor must store ammonia and operate an ammonia dissociator generator. For synthetic, custom-blended atmospheres, processors either buy gases from an industrial gas provider that are stored at the customer’s site, or they generate on the fly using hydrogen or nitrogen generation systems. Storage of purchased industrial gases introduces costs and risks dependent on the specific gas stored, with hydrogen being among the more expensive to store, introducing meaningful site compliance and safety considerations.

Are there limitations to how much and where I can store ammonia or hydrogen gas for furnace atmospheres?

Both ammonia and hydrogen are considered by the EPA and OSHA as Highly Hazardous Materials, and for that reason are subject to rigorous regulations around storage practices and allowed stored quantities. The goal of these practices and regulations is to minimize the likelihood of a release, to minimize the damage to facilities and the community, and the danger to personnel in case a release does occur.

One limitation imposed by the regulations is a limitation of stored inventory of ammonia or hydrogen to 10,000 lbs unless rigorous, burdensome management practices (EPA/OSHA PSM and RMP policies) are implemented. The net effect of these regulations is to make it attractive for users of hydrogen and ammonia to stay below 10,000 lbs stored. Ironically, limited storage has the effect of increasing the actual number of gas deliveries to keep up with the business’s rate of use, as deliveries are the most likely time that a release will occur, limiting inventory has a debatable benefit.

One technique for complying with the EPA/OSHA inventory restrictions is to install smaller tanks, that cannot reach 10,000 lbs of inventory. In many cases, customers elected to have their suppliers change out old larger-capacity storage tanks for smaller ones to ensure compliance. In other cases, customers did not have their tanks switched out, but elected to use Management Controls to instruct their suppliers to only partially fill their large tanks. Management Controls are allowed by the regulations as a means to comply with the regulations. Management Controls reduce the recognized (out-of-pocket) costs but introduce invisible costs in terms of management time and risk of non-compliance.

What is the composition of a typical furnace atmosphere? What are the benefits of hydrogen atmospheres in thermal processing?

Most ferrous and non-ferrous metals are thermally processed in a protective atmosphere. Most furnace cover gases are primarily nitrogen, which is inexpensive, dry, and inert up to considerable temperatures. Some metals, for example, aluminum, can be heated to high temperatures with just a nitrogen protective atmosphere, but most metals require an atmosphere containing a reducing gas to protect the metal from oxidation damage. Atmospheres containing a reducing gas have lower free (molecular) oxygen available for reaction with the metal – because the reducing gas preferentially reacts with the oxygen – making it unavailable to oxidize the hot metal.

The two most common reducing gas constituents in a protective atmosphere are hydrogen and carbon monoxide. Carbon monoxide is a constituent of generated endo and exo atmospheres, typically used when metals are being treated (carburized) to increase their carbon level to harden them – examples might include saw blades or gears. Carbon monoxide is an effective reducing agent, and also powerful carburizing gas.

For heat treating not involving hardening the metal, hydrogen is by far the predominant reducing gas constituent. Hydrogen in blended atmospheres generated DA gas, and even as a constituent of exo and endo gases, is a powerful and efficient oxygen scavenger – a sort of a Mr. Clean to remove and tie up oxygen from furnace atmospheres.

Certain metals, such as 300 series stainless, are preferentially heat treated in a 100% hydrogen atmosphere because the metal properties can be damaged by exposure to nitrogen at high temperatures.

What are the disadvantages of using disassociate ammonia for thermal processing atmospheres?

While dissociated ammonia is a historically important atmosphere for general-purpose heat treating, there are several disadvantages to using it today. The most important disadvantage is that this general purpose atmosphere does not optimize the properties of the metal part in most cases, it can be widely used and gives acceptable results, but it rarely provides optimum results. Hence blended atmospheres can optimize the appearance and performance of fabricated metal parts in ways that dissociated ammonia atmospheres cannot. Additionally, the cost of metallurgical grade ammonia is rising at a faster rate than other atmosphere approaches, reducing its’ ability to compete. If DA is not cheaper, why bother with a non-optimum atmosphere? Most importantly, the legal and regulatory environment around ammonia distribution and storage is becoming much more challenging. The threat of accidental leaks, delivery-caused mishaps, and ammonia system sabotage by drug ingredient thieves is continuous, and the penalties imposed on facilities whose ammonia leaks are punitive.

Beyond all the non-processing disadvantages of dissociated ammonia, it is really not a very good atmosphere, it is often wetter than desirable and it cannot be used with certain metallurgy.

What advantages does on-site hydrogen generation provide thermal processing facilities?

On-site hydrogen generation enables thermal processing facilities to get all of the advantages of blending their own custom atmospheres but without the need to store hydrogen. Hydrogen generation makes hydrogen at the exact rate that the gas is being used, eliminating stored hydrogen. Because all of the relevant regulations are driven by hydrogen storage, generating hydrogen essentially eliminates compliance risks and costs.

An additional benefit of hydrogen generation is cost certainty. Because processors must be able to predict their production costs in order to price their products, cost certainty is a huge benefit. Generated hydrogen has a much higher degree of cost predictability than delivered hydrogen, where the price can change at the whim of the provider.

Finally, generated hydrogen is extremely pure and dry. Purer hydrogen can produce better processing results. Normally, processors have to pay their suppliers extra for highly pure hydrogen, but with hydrogen generation, that benefit comes along at no extra cost.

Can users of on-site generation use the same atmosphere mixes as they did prior to switching?

Blended atmospheres can be designed to exactly duplicate the generated atmospheres that they are replacing, but oftentimes the performance of the atmosphere can be improved, and the cost reduced with a more tailored formulation. Generated atmospheres such as endo, exo, and DA have standardized formulations. These generated atmospheres also tend to contain a higher moisture level than is generally considered optimum. Blended atmospheres made from high purity delivered or generated pure gases can be blended to precisely the formulation needed to enable the results required. Because these pure gas constituents are extremely dry, a leaner atmosphere blend (less hydrogen, more nitrogen) will often perform the same or better than a richer generated gas blend. By using just the minimum amount of reducing hydrogen gas, the cost of the blended atmosphere can be minimized while yielding superior atmosphere results.

Can nitrogen for blended atmospheres be generated on-site?

Hydrogen generation yields multiple benefits for atmosphere blending, including easier and less expensive permitting, installation and compliance. The generated hydrogen gas is often purer and drier than delivered gaseous hydrogen and is similar in quality to delivered liquid hydrogen. In many ways, generated hydrogen is a superior product to the delivered alternative. By comparison, generated nitrogen for heat treat atmospheres is generally chosen to save money while providing nitrogen at a considerable cost savings.

Carefully chosen and specified nitrogen generation equipment can yield excellent thermal processing results. It is critical for processors to understand their own processes and work with a nitrogen generator supplier experienced with nitrogen-blended atmospheres for thermal processing. Because generated nitrogen has a higher oxygen content than delivered liquid nitrogen, the atmosphere blend of hydrogen and nitrogen must be specified to ensure that there is sufficient hydrogen to make up for the higher oxygen content of the generated nitrogen. When specified correctly, the results are a drier, cleaner atmosphere that contains less hydrogen as a percentage than for example a DA atmosphere, while yielding better thermal processing results at a lower cost.

Where can the hydrogen generator be located?

Nel PEM hydrogen generators are designed and certified to meet the predominant applicable safety codes for general-purpose equipment applicable in the US, Canada, and Europe. Our systems have been field-certified in many other geographic regions as well. General-purpose equipment means that the Nel hydrogen generator can go into any non-flammable environment, and its presence and operation in that area does not change the hazard rating of the area. This creates a significant advantage by lowering the cost of installation as compared to stored hydrogen or generators that require an explosion-proof room.

In most cases, Nel hydrogen generators are placed relatively nearby the processes they are supplying, primarily for operator convenience. However, that is not required because they discharge hydrogen at a pressure level considerably higher than is normally used in furnaces, the hydrogen can be piped from the generator as far as necessary within a facility.

Nel hydrogen generators are often located in utility areas housing other utility/process equipment such as air compressors, pumps, and water treating equipment. This space tends to be the least expensive area on a site, and therefore attractive for equipment siting.

What are some considerations for thermal processers looking to make the switch to on-site hydrogen generation?

There are several considerations that come into play when deciding if a change to on-site hydrogen generation is the best solution for your site:

- What challenges are hindering your present approach? Cost? Compliance? Production speed? Parts quality? Metallurgy issues? All of these can be improved by choosing the best atmosphere for your production.

- What is your operating schedule? Hydrogen generation (like any generation) yields the best economics with high operational time.

- What are you using today? Hydrogen generation is an ideal, drop-in replacement for delivered hydrogen and also for delivered ammonia/DA generation. Hydrogen generation is not a drop-in replacement for exo and endo in most cases, because the carbon content in those atmospheres is functional and hardens the parts being processed. Hydrogen can be used along with other carbon-containing atmosphere components for hardening operation.

- Will your customer benefit from improved parts quality, and will that provide you added revenue or increased success in working with that customer?

- Does your site permit you to store hydrogen or ammonia? If you can’t store gases, then your choice is clear to go with a zero-inventory solution.

About Dave Wolff

-1.jpg)

Dave Wolff has over 35 years of project engineering, industrial gas generation and application engineering, marketing and sales experience. He has been a Sales and Marketing leader for Nel Hydrogen since 1999, responsible for sales management in the Eastern USA region.

Dave has an extensive background in hydrogen generation at large and small scale, hydrogen distribution, storage and industrial utilization, and has application knowledge across a diverse range of industries.

NEL

Nel is a global, dedicated hydrogen company, delivering optimal solutions to produce, store and distribute hydrogen. We serve industries, energy and gas companies with leading hydrogen technology. Nel has a history of development and continual improvement of hydrogen plants. Providing solutions that meet global hydrogen requirements for material processing applications including powder metallurgy, MIM, heat treating, and float glass manufacturing. Our patented Alkaline and Proton® PEM electrolysis systems coupled with uncompromising attention to excellence and quality enable us to partner with leading research institutions, governments and militaries. Globally Nel delivers, installs and supports gas generation units on every continent.

www.nelhydrogen.com

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.