Shear testing supplies shear property data for material specifications, quality assurance, research and development, and structural design and analysis. Shear properties may be calculated using different test types including flexion, tension, and compression in addition to different test set-ups like the lap shear method, V-notched rail technique, short beam technique, to name a few.

Image Credit: Admet, Inc. - Materials Testing Equipment

Shear Testing Definitions

Common measurements obtained from a shear test include:

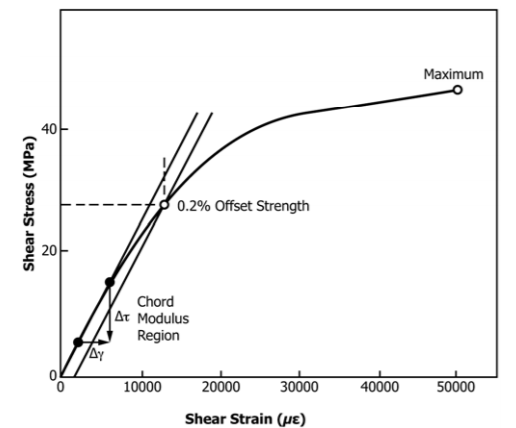

Offset Shear Strength

The offset shear strength is the shear stress endured by a material at the intersection of the shear stress versus the engineering shear strain curve, with a line parallel to a defined modulus and translated from the origin by a specified strain.

Shear Strength

The shear stress carried by a material at failure under a pure shear condition or the maximum load a material can endure in a direction parallel to the face of the material, as opposed to perpendicular to its surface.

Tensile properties such as tensile strength and compressive properties like compressive strength can also be calculated by shear loading.

- ASTM D3410 uses wedge grips which are specially designed to apply shear loading in compression. Properties measured include Poisson’s ratio, compressive stress, compressive strain, and Modulus of Elasticity.

- ASTM D3518 establishes the in-plane shear response of polymer matrix composite materials by a tensile shear test. Properties calculated include the shear modulus, shear stress, shear strain, and chord shear Modulus of Elasticity.

Factors that affect the shear response and so, should be reported, include:

- Material

- Methods of material preparation and lay-up

- Specimen stacking sequence

- Specimen conditioning

- Specimen preparation

- Void content

- Volume percent reinforcement

- Specimen alignment and gripping

- Environment of testing

- Speed of testing

- Time at temperature

Adhesives and Lap Shear Testing

A common type of shear test which is frequently carried out on adhesives is known as lap shear testing. Adhesives are utilized in construction, electronic and aerospace applications.

They can join parts together by transferring stress from one member (substrate) to another in a manner that distributes the stress more evenly than can be attained using mechanical fasteners.

Often, adhesive bonding supplies joints which are mechanically equivalent to, or stronger than, those joined by fasteners as a result of this. The aim of joint design is to acquire optimum strength for a given bond area.

Factors which influence joint design are the joint geometry, the mechanical properties of the adhesive and substrate, and residual stresses resulting from adhesive cure. In addition, coatings or interstitial layers between the substrate and adhesive will cause weak bonds.

Solvents, sunlight and heat may weaken an adhesive; load-induced stresses may also result in adhesive joint failure at different locations within the joint. Therefore, a good joint design should keep stress concentrations to a minimum in order to reduce the overall strength of the joint.

Image Credit: Admet, Inc. - Materials Testing Equipment

There are various types of adhesive joints for carrying shear loads, the most effective use an overlapping substrate arrangement known as lap joints. The overlapping area should be big enough to permit the joint to withstand maximum shear service loads.

Increasing the width of the joint results in a proportional increase in joint strength, whereas increasing the overlap length beyond a certain amount does not have much effect on joint strength.

Three common specifications for lap shear testing are:

- ASTM D3164 – Standard Test Method for Strength Properties of Adhesively Bonded Plastic Lap-Shear Sandwich Joints in Shear by Tension Loading

- For substrates that have been joined by plastic rather than adhesive

- ASTM D3163 – Standard Test Method for Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension Loading

- For utilization with rigid plastic substrates

- ASTM D1002 – Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading

- For metal substrates that are bonded by an adhesive

Each of these specifications employ a single lap joint (lap shear) specimen to establish the shear strength of adhesives.

Testing Equipment

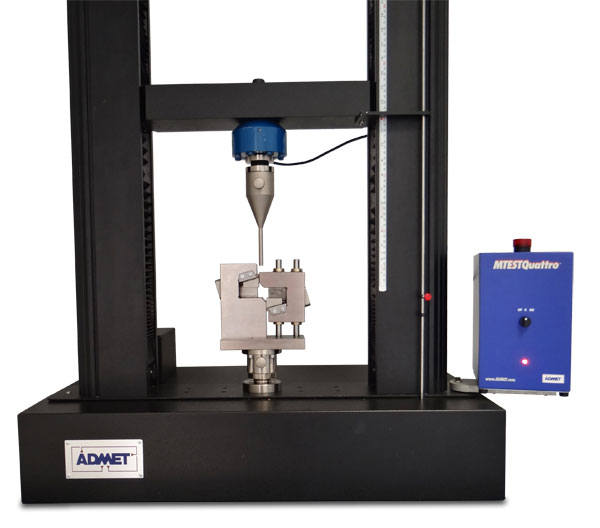

To run shear tests, universal testing machines with closed loop servo-controllers are recommended. The testing machine should be able to move at a controlled, uniform rate of loading so that the load can be applied with a continuous motion.

Force and displacement transducers should supply an accuracy of within +/- 1 % of the indicated value. eXpert 1000 servo-hydraulic testing systems and eXpert 2600 dual column electromechanical testing systems are universal testing machines that are frequently utilized for shear testing.

ASTM D1002 test setup with wedge grips on an eXpert 1600. Image Credit: Admet, Inc. - Materials Testing Equipment

Vise grips, or wedge grips can be utilized in shear test setups depending on the required force capacity. To perform a lap shear test, it is vital to ensure that the grip inserts are aligned so that the centerline of the grip assembly is in proper alignment with the adhesive bond.

Vise grips have T-handles that permit adjusting the grip inserts from side to side. Wedge grips do not have the ability to offset the centerline, alternatively, for specimen alignment, they can be supplied with spacers.

The majority of testing standards outlining shear test techniques include descriptions on fixturing to test specimens. So, specially-designed shear fixtures are available per testing standards. Examples of these are outlined below.

Developed by the University of Wyoming Composite Materials Research Group, the ASTM D5379 shear test fixture, is utilized with reinforced composites. Each half of the fixture contains a wedge-action grip which clamps one half of the test specimen lightly across the specimen width and supports the specimen on its back face.

One of the grips, usually the lower half, is mounted on a base plate, which also supports a linear bearing shaft, while the other grip, usually in the upper position, contains a linear bearing that mounts over the shaft on the base.

Specialized shear fixture on an eXpert 2600 for ASTM D5379. Image Credit: Admet, Inc. - Materials Testing Equipment

By means of an alignment tool that references the fixture, the specimen is inserted into the fixture with the notch located along the line of action of loading. Using a testing machine, the two halves of the fixture are compressed while monitoring the force. The relative displacement between the two fixture halves loads the notched specimen.

By placing two strain gauge elements, in the middle of the specimen (away from the notches) and along the loading axis oriented at 45° to the loading axis, the shear response of the material is calculated.

ASTM C273 fixture on an eXpert 2610. Image Credit: Admet, Inc. - Materials Testing Equipment

ASTM D905 can be utilized for shear testing of wood samples. The test specimen is placed in the self-aligning guillotine-like shearing tool when cutting specimen blocks, which ensures that the force applied is perpendicular.

ASTM C273 shear fixture is made up of two loading plates and can be employed to test sandwich core materials. The test specimen is supported by these loading plates bonded to the facings.

This information has been sourced, reviewed and adapted from materials provided by Admet, Inc. - Materials Testing Equipment.

For more information on this source, please visit Admet, Inc. - Materials Testing Equipment.