ZwickRoell is a supplier of innovative solutions that feature a large variety of specimen grips and test tools with an array of designs, test temperatures, and test force ranges.

How to Select the Test Method

- The specimen needs to be held properly during each test to provide safe and reliable testing with the production of results that are accurate. This can only be done if the specimen grip and test tool function correctly. This proves the importance of choosing the correct specimen grip for every test.

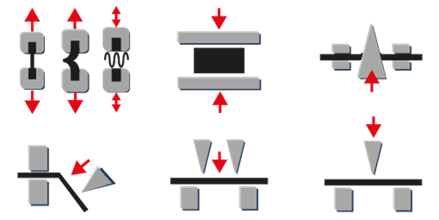

- ZwickRoell offers a comprehensive portfolio of specimen grips and test tools that cover an array of applications for tensile tests, compression tests, flexure tests, cyclic tests, and shear tests.

Image Credit: ZwickRoell GmbH Co. KG

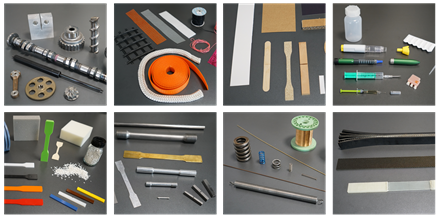

Selection: According to Specimen Material and/or Shape

- Variations in how it is designed and how it works mean that each specimen grip is suitable for a range of specimen shapes, material properties, and dimensions, as well as for the corresponding force and deformation ranges.

- Specific properties are given for the range of materials and are important factors to consider when choosing the correct specimen grips. Examples of these properties are ductility, strength, hardness, elasticity, and surface type or condition.

Image Credit: ZwickRoell GmbH Co. KG

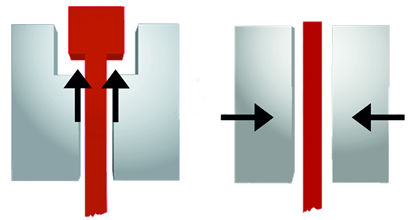

Selection of Operating Principle and Mechanical Requirements

- Taking the specimen shape into consideration, the load can be transferred either positively or non-positively. However, due to being a derivative of wires, belts, straps, sheet metals, or other sheet materials, it is only appropriate to transfer most tensile specimens non-positively. Self-tensioning and externally actuated specimen grips can be selected, depending on the gripping force needed and the amount of available gripping area.

- The mechanical requirements put on specimen grips differ tremendously, from the required force range and opening width to variations in temperature ranges.

Image Credit:ZwickRoell GmbH Co. KG

Compliance with General Requirements

- When making a selection, standard specifications and general test requirements play an important role. For instance, if the specimen throughput is high, the automatic application of the gripping force is recommended, and thus the provision of pneumatic and hydraulic grips is suggested.

- If there is a requirement for a certain number of tests to be performed, flexibility should be a main priority for the specimen grip chosen. With the grip being as flexible as possible, changeover, time, and the cost are reduced, yet operating convenience is enhanced.

Image Credit: ZwickRoell GmbH Co. KG

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG