Many people associate automation with industrial robots or completely automated handling systems.

Utilization of intelligent wizard functions or semi-automation allows the optimization of testing processes for plastics and polymers. This relieves users of repetitive tasks and helps prevent operating errors. Simultaneously, these functions create an ideal situation for a switch to complete automation.

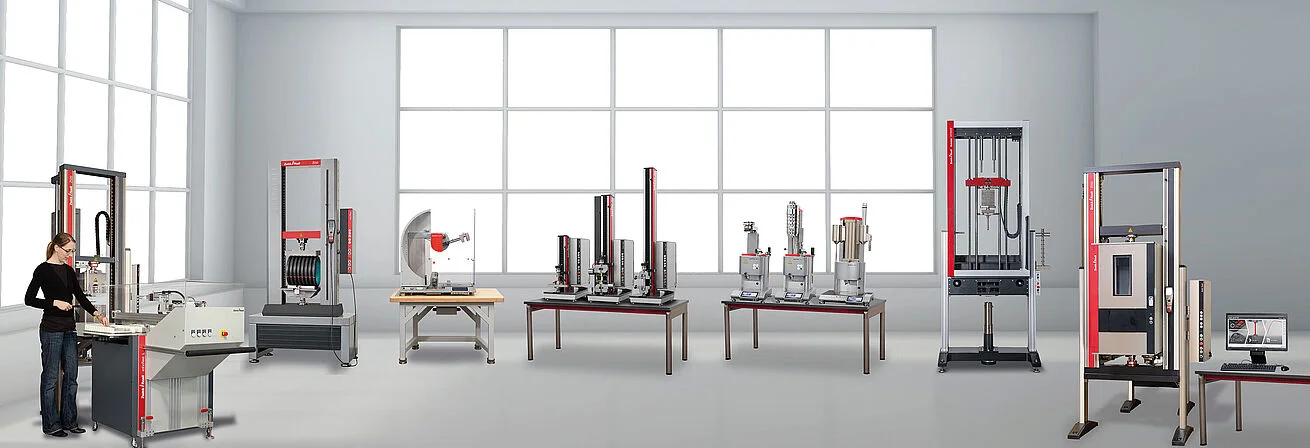

This article explores the transformation of plastics testing with cutting-edge automation, optimizing laboratory efficiency seamlessly.

Image Credit: ZwickRoell GmbH Co. KG

Modern Testing Software: The Foundation for Every Automation System

The intelligent assistant functions within testXpert guarantee dependable and effective testing right from the beginning. This includes pre-configured test programs, available for over 800 local and international standards, and adaptable test environments.

For instance, it incorporates sensor recognition and a broad range of safety functions, extending to thorough plausibility checks. Even in its basic form, testXpert provides many features that accelerate testing processes by up to 30 percent and reduce operational and data input errors.

Image Credit: ZwickRoell GmbH Co. KG

Specimen Grips and Extensometers

Image Credit: ZwickRoell GmbH Co. KG

The use of automated specimen grips and extensometers provides three distinct advantages.

Firstly, automated gripping (specimen grip) and automated attachment, along with specimen mark recognition (extensometer), accelerate test tasks by up to 50 percent when compared to manual specimen grips, like screw grips or clip-on extensometers.

The second advantage is an increase in repeatability. Automated functions decrease operator influences to the lowest possible extent. Specimens are gripped with the same accuracy. Extensometers, such as makroXtens, are always attached identically, or the specimen marking is always recognized identically, such as videoXtens.

Lastly, a crucial advantage in terms of future investment viability is that with the use of automated specimen grips/extensometers, transformation to a completely automated system is feasible at any time. The basic requirement for integrating a smart robot or handling system is the use of automated individual components.

Full Automation

Due to the progress of collaborative robots, commonly known as cobots, and the continuous improvement of simple handling systems, complete automation becomes a feasible choice, beginning with specimen series as low as approximately 25 specimens/day.

In industrialized countries, this kind of investment pays for itself in as little as two years. This kind of retrofit can be applied to static testing machines (for tensile, compression, or flexure tests) as well as pendulum impact testers. Several testing machines and test types can also be incorporated into an automation project.

Beyond purely economic considerations, there are two additional benefits: user influence on the test results is significantly reduced, and laboratory personnel can be assigned to other tasks that require higher skills.

Image Credit: ZwickRoell GmbH Co. KG

This information has been sourced, reviewed, and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG.