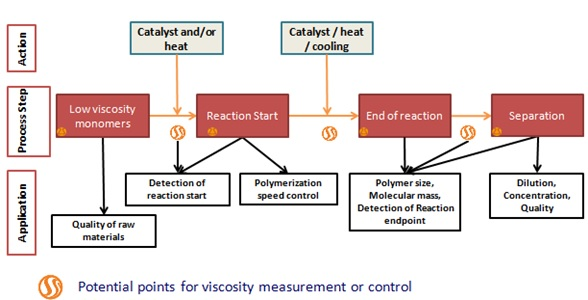

Polymers are high molecular mass molecules consisting of repeating units known as monomers that are linked by covalent chemical bonds. At the beginning of a batch type process the content of the reactor has a low viscosity and primarily consists of monomers.

Once heat and/or a catalyst are introduced, the process of polymerization begins and viscosity becomes higher. Viscosity is an indirect way of quantifying the molecular mass of polymers.

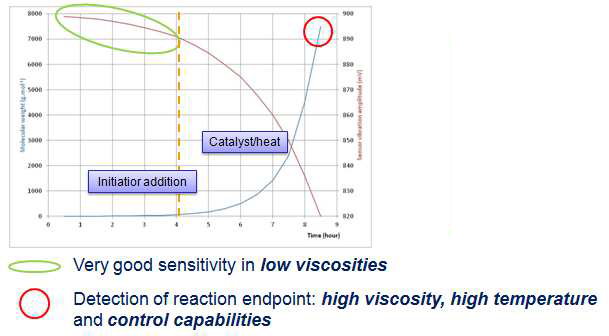

Figure 1. Simplified polymerization principle.

Phenolic resins are commonly made for paper impregnation and gluing. They provide exceptional product features regarding material resistance and toughness, but the conditions of its production are challenging due to its reaction process.

Batches are never precisely the same because the range of ingredients are sourced from multiple suppliers. Every batch is weighed prior to mixing and then a reactor is used to heat them for a production cycle.

The viscosity and temperature of the solution are important parameters throughout this cycle. As the reaction is exothermic, heating will continue even after the heating process has stopped.

The heating process involves distinct phases and has highly sensitive viscosity and temperature values that must be monitored. If the resin becomes hard and a discrepancy arises, an unusable product is not the only consequence, but also possible damage to the reactors and pipes.

Challenges

- If the exothermic phenolic resin polymerization reaction happens too quickly, it causes:

- Polymer hardening (making it impossible to halt the reaction)

- Poor polymer quality (heterogeneous)

This results in significant wastage of raw material, lengthy downtime for complex maintenance, delivery delays, additional labor costs, and may require enormous replacement costs.

- If the reaction is too slow, the consequence is:

- Lack of final product (the product fails to meet specifications)

- Low productivity (energy consumption and loss of time)

- Viscosity is a physical feature of the product and the reaction must cease precisely when the necessary viscosity has been achieved. When this happens:

- The product can be stocked (methylmethacrylate, polyisobutylene, polyurethane, polystyrene, glues, and resins)

- The product is ready to be utilized (extruded, molded, laminated)

The challenges related to viscosity in batch process polymerization are:

- Reaction start detection

- Control of raw materials

- Quantification of molecular weight

- Polymerization speed control

- Reaction end-point identification

- Chain-length characterization

- Concentration

- Polymer dilution control

- Finished product quality control

Solution

Installing an inline MIVI process viscometer provides simple observation of the endpoint of the polymerization reaction. It assists in the identification of the ideal temperature and viscosity parameters, and avoids mass solidification.

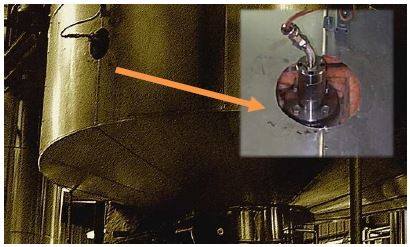

Installation

The Sofraser MIVI sensor can be simply installed:

- In an immersion tube

- On a reactor wall

- On a bypass loop

The controller or electronics enables the operator to observe, in real-time, the temperature and viscosity values and to monitor safe and accurate batch process operations.

Figure 2. Onsite installation directly on the reactor wall.

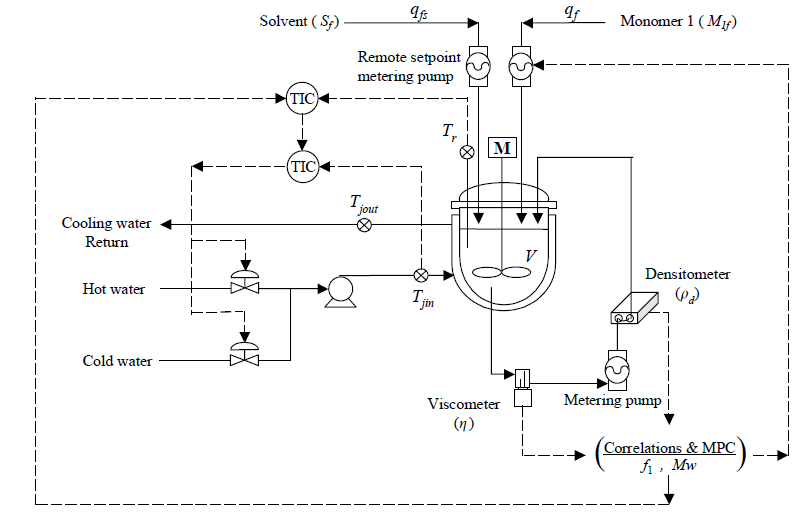

Figure 3. Operation diagram of a MIVI sensor on a semi-batch MMA/MA solution copolymerization reactor system. Image Credit: School of Chemical Engineering and Institute of Chemical Processes, Seoul National University.

Capabilities

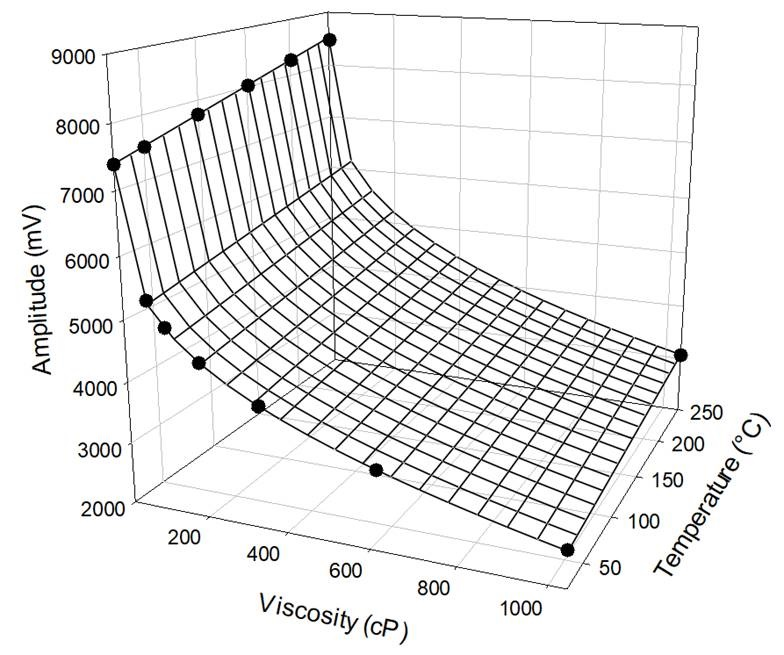

Thanks to its specific raw signal versus viscosity response the MIVI sensor offers a high degree of sensitivity at low viscosity combined with a very broad measurement range.

Figure 4. Response curve of a MIVI sensor for polymerization monitoring

This specificity allows the MIVI sensor to monitor the polymerization batch from the beginning to the end point.

Figure 5. MIVI viscometer capabilities.

Key Product Characteristics

- Reliable and repeatable

- Good sensitivity at low viscosity in combination with a high full-scale range

- No drift over time, no maintenance, and no wearing parts

- Simple installation with a range of mounting positions

- Ex-proof certifications

- Self-cleaning

- Temperature probe

- Alarms for control and resistance to overshoots

- High pressure

- Several different coatings for corrosive materials

.png)

This information has been sourced, reviewed and adapted from materials provided by SOFRASER.

For more information on this source, please visit SOFRASER.