Image Credit: koya979/Shutterstock.com

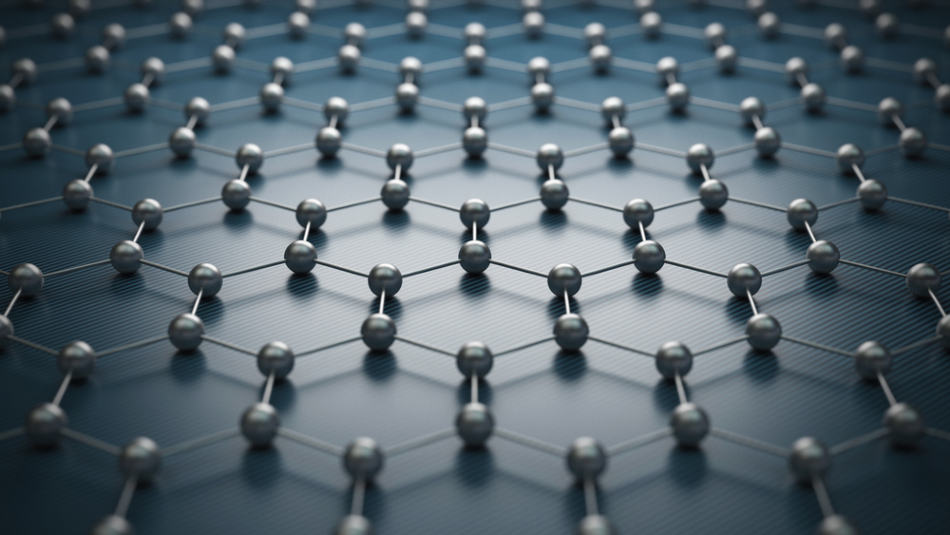

Since it was discovered and isolated back in 2004, the single atomic layer of carbon known as graphene has been intensively investigated, with scientists exploring how its unique and impressive characteristics can benefit a wide range of industries.

So far, graphene has thrived, finding uses in applications in electronics, sensors, renewable energy, pharmaceuticals, construction, and more. There is a high demand for the material, and scientists at Rice University have developed a way to create it from trash for use in strengthening concrete and other composite materials, which will reduce the environmental impact of the construction industry.

Transforming Carbon Sources into Turbostratic Graphene

In a paper published in the scientific journal Nature, a team of scientists from Rice University describes how they developed a method that can successfully transform any source of carbon into turbostratic graphene, including waste products. The technique uses high-energy pulses of electricity to achieve this transformation, which produces graphene flakes from anything such as coal to food waste.

The benefits of the innovation are that it drastically reduces the cost of alternative methods of bulk-producing graphene, as well as offering a solution to recycle items such as plastics that may end up in landfill, and rotten food which causes the population to dispose of up to 40% of the food it would otherwise consume.

'Flash graphene', as it is known, is produced by heating carbon-containing substances for 10 milliseconds at 3000 Kelvin. Researchers proved their method to be effective at creating graphene from a wide range of sources, including food waste, plastics, tires, petroleum coke, coal, and wood clippings.

The method looks as though it will be a lucrative one, given that a ton of graphene currently fetches around $67,000 to $200,000 commercially. It also looks set to transform the construction industry, as an addition of just 0.1% of flash graphene added into cement can reduce the environmental impact of this heavily used material by a third. Because adding graphene into concrete enhances its strength, less is needed, resulting in a reduction in manufacturing and transport requirements. This will be significant in reducing emissions as the product currently accounts for around 8% of the total human-made carbon dioxide emitted annually.

Food waste is also a huge contributor to methane emissions, and therefore, the flash graphene method will also be instrumental in reducing emissions by preventing food from ending up in landfills where it emits the greenhouse gas as is decomposes.

Previously, graphene has been too expensive to be used in these applications. With the new cost-effective flash graphene method, these emission-reducing strategies will be able to be implemented.

Concrete is not the only material that flash graphene will be used to make. Other products such as cars, asphalt, and even clothing will benefit.

Making graphene from trash in less than a second

"Turbostratic" Graphene

The technique the team developed was inspired by chemical vapor deposition on metal and exfoliation from graphite methods that also produce graphene, but at much higher costs with a lower output. The new method also produces "turbostratic" graphene rather than A-B stacked graphene, which is constructed from misaligned layers that make it easy to break apart. This form of graphene is far easier to work with, allowing it to be used in a broader range of applications. Coffee grounds, in particular, were noted as producing perfect single-layer sheets of graphene.

Scientists predict that materials such as concrete, plywood, and other building materials are those that present the biggest market for flash graphene. Currently, testing is already underway to investigate how flash graphene performs in creating concrete and plastics.

To produce flash graphene, a custom-built reactor is used to rapidly heat the material, expelling all material that is not carbon as a gas. Scientists envision that when the process is used industrially, it will be updated so that valuable byproducts such as oxygen and nitrogen can be collected. Because excess energy is released in the form of light, as a bright flash, the process has been given its name, flash graphene.

The process was initially being explored to investigate how it could be used to create phase-changing nanoparticles. However, researchers on the project quickly realized that the method was only producing high-quality graphene.

Tests have determined that it is the high temperature that is vital to the transformation of carbon into graphene, with scientists at Rice explaining that the high temperature has the effect of speeding up what is usually a slow geological process that sees carbon evolving into graphite, stopping it at the instant where it converts into graphene.

The team plans to produce a kilogram of flash graphene daily within two years. The Department of Energy has recently awarded funding to the project, which will see the team first work with converting coal into graphene, offering a method of producing graphene from a cheap and abundant source.

Click here to find out more about the equipment used for material processing and manufacturing.

Sources and Further Reading

- Cai, M., Thorpe, D., Adamson, D. and Schniepp, H., 2012. Methods of graphite exfoliation. Journal of Materials Chemistry, 22(48), p.24992. https://pubs.rsc.org/en/content/articlelanding/2012/jm/c2jm34517j/unauth#!divAbstract

- Luong, D., Bets, K., Algozeeb, W., Stanford, M., Kittrell, C., Chen, W., Salvatierra, R., Ren, M., McHugh, E., Advincula, P., Wang, Z., Bhatt, M., Guo, H., Mancevski, V., Shahsavari, R., Yakobson, B. and Tour, J., 2020. Gram-scale bottom-up flash graphene synthesis. Nature, 577(7792), pp.647-651. https://www.nature.com/articles/s41586-020-1938-0

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.