It is important that the correct crucible is selected when designing a new glass melt in order to safeguard the glass melt from deformation, cracking, or contamination by the crucible.

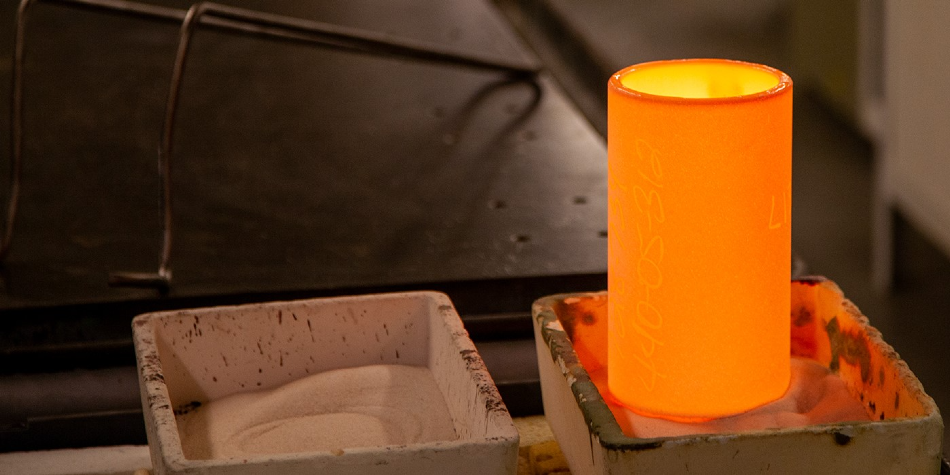

Image credit: Mo-Sci Corp.

Crucibles often require an extended working lifespan as they are used again and again. Any downtime created by a crucible being inoperative is likely to halt large elements within the process of manufacturing, which can be incredibly expensive.

The composition of the crucible should be assessed for characteristics such as its resistance to thermal shock, maximum operating temperature, compressive strength and possible reactions with the glass1, expansion coefficient, along with the cost and longevity of the material.

Silica

Silica (SiO2) is an oxide that can function at high temperatures without degrading chemical composition and structural integrity. Its maximum operating temperature of 1500 °C is lower than alternative materials, such as alumina.

With an exceptionally low coefficient of thermal expansion and a higher resistance to thermal shock, silica is the ideal choice for melting a number of glass families for example borosilicates, silicates, and soda-lime.

Alumina

Alumina (Al2O3) is a suitable candidate for melts that require high temperature stability, but where cost is also a factor. Alumina transfers heat from the furnace faster as it has a high thermal conductivity.

It also offers effective thermal shock resistance due to its low coefficient of thermal expansion. For high purity Al2O3, the maximum operating temperature is 1700 °C.

Another useful attribute is its resistance against chemical attack which can result in melt contamination and significant degradation of the crucible. Its resistance is even stronger than platinum in the application of heavy metal oxide (HMO) glass melting.2

AZS (alumina-zirconia-silica)

AZS is one of the most frequently utilized refractories in the production of commercial glass. It can endure high temperatures along with having a high resistance to corrosion.3 The oxides that form AZS are affordable, and the subsequent mixture can be cast into a wide range of crucible shapes.

The main limitation is that when a glass melt contacts the walls of the AZS crucible, flaws like knots and bubbles can be produced, leading to a compromised structure.

This is a serious issue, particularly in the production of industrial glass where it is predicted that up to 10% of the glass created in continuously operating furnaces is rejected. The creation of ultra-low exudation AZS is one solution that is being explored.4

Platinum

Platinum is one of the first choices for researchers aiming to avoid sample contamination as it is one of the noble metals and is highly inert.5 Its rarity and difficulty in mining means that it is a costly choice for crucibles.

Platinum is frequently alloyed with rhodium in ratios of 90:10 or 80:20 to decrease the cost without compromising on function.

The operating temperature can be increased to approximately 1600 °C; 300 °C higher than that of pure platinum through this method.6 As platinum is also a relatively malleable metal, it can easily be formed into crucibles of various sizes and shapes.

While it is resistant to most types of corrosion, platinum crucibles can be harmed by heavy metal oxide glasses, resulting in the degradation of features in the end material.

Vitreous Carbon

The thermal decomposition of a cross-linked polymer creates the ceramic material called vitreous carbon.7 Due to its high sheen and black color, it is also known as ‘glassy’ carbon. It is quite fragile, similar to glass, but it has other important characteristics that make it suitable for being a crucible material.

It is resistant to thermal shock, along with having a high operating temperature of up to 2500 °C. As it contains carbon, it has a comparatively high thermal conductivity.

An important feature is that it is unaffected by gas and has incredibly low porosity. It is also highly resistant to damage by many chemicals such as chromic, sulfuric, nitric, hydrofluoric, and hydrochloric acids.

It is more costly than different ceramic crucibles like alumina, but has a longer lifetime as a result of its stability throughout thermal cycling.

Fire Clay

Clay is found in abundance, is easily formed into a broad range of shapes, and is a material that has been used throughout history for glass melt crucibles.

Contemporary fireclays can also be customized to distinct applications by modifying the composition with oxides and further additives.8 The addition of widespread compounds like MgO, CaO, K2O, and Na2O can significantly raise the maximum operating temperature.

Certain fire clays can be high in silicon oxide (SiO2) which decreases the resistance to thermal shock, and some may contain a high porosity. Pores can enable the crucible to be penetrated by the glass melt, heightening the risk of contamination and even resulting in the breakage of the crucible itself.

References and Further Reading

- J.E., S. Introduction to Glass Science and Technology. doi:10.1017/CBO9781107415324.004

- Dos Santos, I. M. G. et al. Ceramic crucibles: A new alternative for melting of PbO-BiO 1.5 -GaO 1.5 glasses. J. Non. Cryst. Solids 319, 304–310 (2003).

- Magnificus, D. R. Glass Defects Originating from Glass MelUFused Cast AZS Refractory Interaction. (1994). doi:10.6100/IR417346

- Cabodi, I., Gaubil, M., Morand, C. & Escaravage, B. ER 2001 SLX: Very low exudation AZS product for glass furnace superstructures. Glas. Technol. Eur. J. Glas. Sci. Technol. Part A 49, 221–224 (2008).

- Fischer, B. & Gerth, K. Platinum for Glass Making at Jena. Platin. Met. Rev. 38, 74–82 (1994).

- Improving Service Life of Platinum Crucibles Used for Sample Fusion. AZoNetwork Available at: https://www.azom.com/article.aspx?ArticleID=17601.

- Cowlard, F. C. & Lewis, J. C. Vitreous carbon - A new form of carbon. J. Mater. Sci. 2, 507–512 (1967).

- ‘Crucible’ from DigitalFire.com Reference Library. Available at: https://digitalfire.com/4sight/glossary/glossary_crucible.html.

This information has been sourced, reviewed and adapted from materials provided by Mo-Sci Corp.

For more information on this source, please visit Mo-Sci Corp.