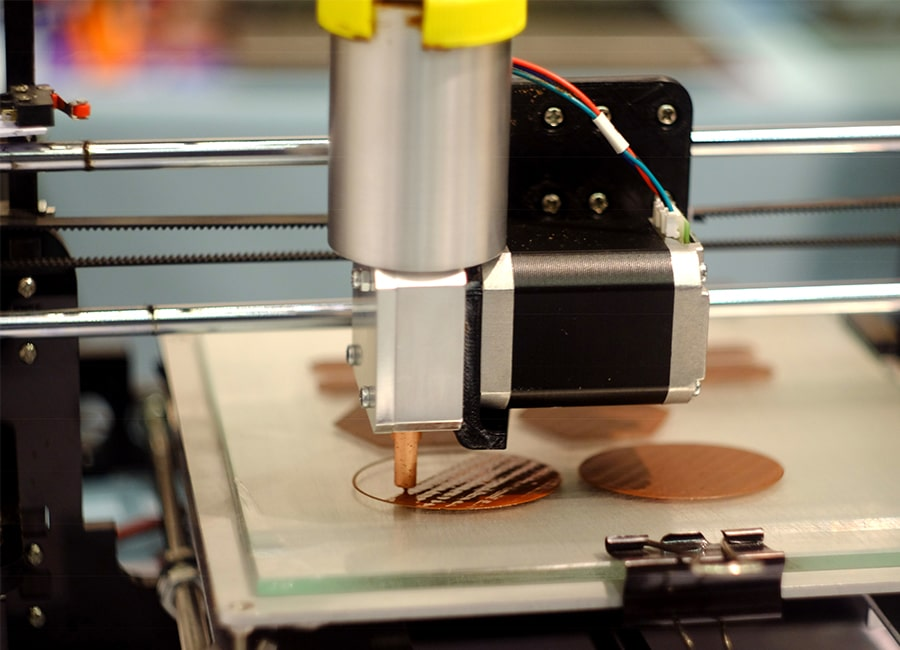

3D printers — machines that can fit on a desktop and create 3D objects from plastics, metals, and other raw materials — can do just about anything.

High-precision jets pump out custom medical implants at the press of a button. Carbon-fiber printers spit out automobile prototypes with jaw-dropping precision. And off-the-shelf modelers generate custom toys, jewelry, home decorations, and clothes with no more than a digital file. But there’s a new frontier in 3D printing that’s only beginning to come into focus: food. Recent innovations have made possible machines that print, cook, and serve foods on a mass scale. Industry leaders think 3D food printers could improve the nutritional value of meals, produce intricate sculptures out of everyday foodstuff, and solve hunger in regions of the world that lack access to fresh, affordable ingredients. There’s no doubt about it — 3D food printing has come a long way.

3D printing is becoming mainstream as a design and manufacture tool in many industries, including the food industry, where innovation is a key marketing strategy; consumers will buy into products that have a new spin on ‘fun’ or ‘healthy’. It is a very useful tool in the food industry, bringing digital design to life through the medium of an edible product and allowing full customization.

Using this tool, a food product or a whole meal can have its ingredients tailored to meet the needs of a patient in hospital or a care home, leading to a better recovery. 3D printing also has the potential to make life easier for those people who use health trackers. There is a possibility that in the future, the user’s fitness tracker can send data to the 3D printer, which will output a meal perfectly tailored to that person’s requirements. This ‘Personalisation’ has been pointed as the driving force to disrupt traditional ways to produce and deliver food and enchant a variety of customers.

By means of extrusion-based 3DFP, for example, three main features can be acquired that cannot be done using conventional casting methods of paste-like materials: (1) the design of internal structures (infill percentages and internal variations of the nutritional content); (2) encapsulation of probiotics, vitamins and nutrients; and (3) freshly mixing of ingredients to ensure the ideal texture within a complex 3D construct (in dual or multiple nozzle systems).

For those with environmental concerns, this method might be appealing as it can use up food that is otherwise destined to be thrown away. This food might not be attractive enough for sale, such as the ugly leftovers from the production process. However, it can be formed into a more appetizing shape with the help of 3D printing. Many people are trying to reduce their meat intake, and this is often for reasons of environmental concern too. 3D printing can help in this area, as it has the ability to use alternative protein sources such as insects. There is a reluctance to eat insects in the West, which is unfortunate as they contain an excellent source of protein and are more environmentally friendly than meat, producing less methane and consuming less water. 3D printing allows insect protein to be reformed into a more appealing shape.

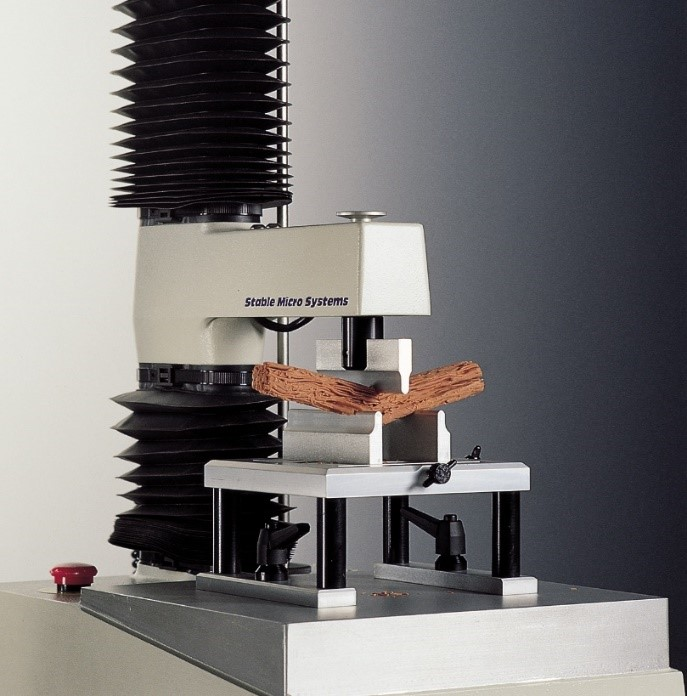

For the consumers who avoid meat for animal welfare reasons, there are companies researching meat that has had its whole structure 3D printed from plant-based materials. A common drawback of plant-based meat substitutes is that their texture is not close enough to the real thing. However, 3D printing allows the structure to be perfectly tailored, fine-tuning it to match the mouthfeel and textural parameters of a real piece of meat. And for that type of research, a Texture Analyzer is essential. The same concept applies to every 3D printed product type: although food has been reformed into a novel shape, its texture must remain appealing.

Stable Micro Systems manufactures instruments that measure the tensile and compressional properties of 3D printed objects and the chosen printing materials. As with any manufacturing innovation, the end product must go through a quality control process to assess its physical properties.

A Texture Analyzer is a crucial part of this procedure, giving a reliable way to test the mechanical (and sensorial) properties of 3D printed objects by applying a choice of compression, tension, extrusion, adhesion, bending or cutting tests to measure a product’s physical properties e.g. tensile strength, snap force, fracturability/crispness, compressibility, to name but a few.

A range of Texture Analyzers varying in maximum force capacity.

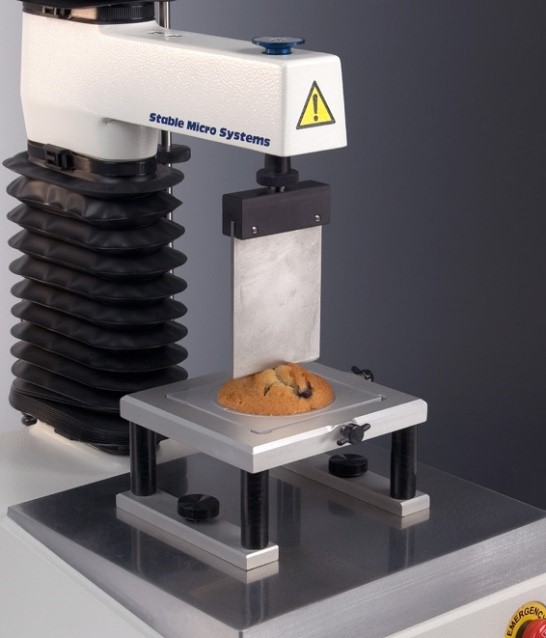

Example of how 3D printing food materials can be tested – Compression & Extrusion

Food materials for FDM printing should have adequate rheological properties that can be easily extruded and maintain their shape. However, there are very few foods that meet this condition and it is still a challenge to process many food materials to be applicable to this method. Any materials that are proposed for 3D printing will require ‘printability’ testing to ensure they possess the correct rheological properties or consistency. Formulations will need to be assessed for their extrudability and the resulting printed products measured by way of a compression test to ensure the texture matches customer expectation.

Typical compression and extrusion tests on a Texture Analyzer.

Example of how 3D printing food materials can be tested – Fracture & Bending

Printed products such as chocolate may need to be tested in a similar way that they are assessed by a consumer. A typical example of this is breaking a bar of chocolate in half. This imitative test can be measured using a 3 point bend rig on a Texture Analyzer. The braking force and flexibility is measured.

A typical three-point bend test on a Texture Analyzer.

Example of how 3D printing food materials can be tested – Cutting

How a printed food is bitten into is another parameter of interest. Varying print materials and the internal infill structure can affect the ‘hardness’ of the end product. Many foods are inserted between the upper and lower incisors and bitten into. The force required to do this gives the consumer an indication of its toughness or ‘bite force’. This type of test can be easily imitated using a Texture Analyzer with a knife blade attached.

A typical cutting test on a Texture Analyzer.

Texture Analysis and Its role at NASA Scientists from The University of Queensland have been researching the optimisation of chocolate 3D printing by correlating thermal and flow properties with 3D structure modelling. They used their TA.XTplus Texture Analyser, along with a custom break probe, to measure the snap force of 3D printed chocolate. The breaking strength of the samples was found to be strongly related to the support structure of the chocolate. This study demonstrated the use of flow enhancer and the inclusion of a support structure in the designed shape were key factors influencing printability capacity of chocolate.

To read more, click or tap here...

Meanwhile, at the University of Jiangnan, scientists have been investigating the creation of internal structure of mashed potato construct by 3D printing, and its textural properties. Although it is relatively a new area of research, most of the papers about 3D food printing have been focusing on the materials' properties or the printing variables on the 3D printing performance. Previous to this paper, limited information on the modified texture properties of printed samples is available, although the 3D printing technique has the ability to change the internal structure of printed objects by varying infill pattern and infill percentages.

In this study, texture attributes of hardness and gumminess were obtained by texture profile analysis using a TA.XT2 Texture Analyser. The study confirmed that 3D printing has a potential to modify the textural properties of 3D printed samples through varying the infill percentage and the printing paths to fill the object, which possibly provides a novel way of tailoring textural properties of manufactured foods.

To read more, click or tap here...

Now that 3D-printing technology has become more vital and relevant than ever, Silicon Valley BeeHex has harnessed this technology (funded by a grant from NASA), to 3D print pizza. The purpose of this invention was to create a way for astronauts to select and product delicious food for themselves on missions.

As manned missions to Mars become an ever-increasing possibility, astronauts might be spending much more time in space. To save space-goers from the drudgery of choking down freeze-dried, pre-packaged “space food” day after day, month after month, NASA decided it was time to develop a way to cook in space. As usual, they will need to make sure that all the key aspects of consumer satisfaction of the resulting printed food are in place and this is where a Texture Analyser comes in!

Now that 3D-printing technology has become more vital and relevant than ever, Silicon Valley BeeHex has harnessed this technology (funded by a grant from NASA), to 3D print pizza. The purpose of this invention was to create a way for astronauts to select and produce delicious food for themselves on missions. As a manned mission to Mars become an ever-increasing possibility, astronauts might be spending much more time in space. To save space-goers from the drudgery of choking down freeze-dried, pre-packaged “space food” day after day, month after month, NASA decided it was time to develop a way to cook in space. As usual, they will need to make sure that all the key aspects of consumer satisfaction of the resulting printed food are in place and this is where a Texture Analyzer comes in!

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.