Spaces used for biological experiments and sterile fill isolator areas (BioSafety Level 3 and 4 rated labs) should receive regular virus deactivation and decontamination. The National Cancer Institute (NIH) Research and Production Center at Ft. Detrick, Maryland, decontaminates rooms and whole areas using vaporized hydrogen peroxide.

Whole Room VHP Sterilization

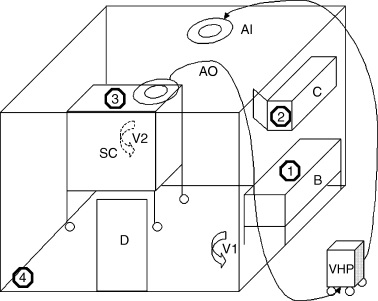

Whole room sterilization is made possible by connecting a vaporized hydrogen peroxide generator to the HVAC system. Numbers above highlight the locations of biological indicators used within the study. In the diagram, places where biological indicators are used could be sensible options for real-time sterilant vapor monitoring.

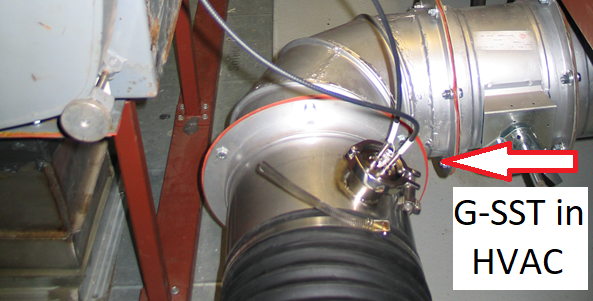

As can be seen below, G-SST probes have been fitted in sterile fill isolators and BioSafety labs at the NIH Center.

Linking these probes to Process Insights’ Hydrogen Peroxide Vapor Analyzer (HPVA), sterilization technicians can confirm that sterilant was correctly dispersed at kill level concentrations within the room.

A G-SST probe will generally be wall-mounted at one or more locations in the room – usually areas that sterilant vapors may struggle to reach. These biological indicators can help to pinpoint an area of the room where the permanent mounting of real-time sterilant concentration monitoring will be valuable.

Long time Sales Representative and Partner, Greg Gargus of Prochem Scientific, inspecting the installation of a G-SST probe during commissioning at NIH building in Maryland, USA.

Inspection of G-SST Vapor Probe for Whole Room BSL3 Lab

The HPVA is a complete NIR analytical system which is made up of three primary components:

- The NIR photometer

- A pair of fiber optic cables for each probe

- The sample interface (in this case the G-SST probe)

The photometer serves two principal functions: transmission of the source light, and quantification of the light that was not absorbed by the sample.

Process grade, thermally stable fiber optic cables are used to transport the light from the photometer to the sample and back again.

The use of high-performance fiber cables allows the sample interface to be situated up to 100 meters away from the photometer. This means that NIR technology is now a viable option for use in biosafety environments.

In settings where several rooms must be decontaminated in sequence, it is possible to install multiple probes - or one probe per room - before serially monitoring each location/fiber pair.

Connecting the fiber optic cable pairs to the Hydrogen Peroxide Vapor Analyzer in order means that the decontamination cycle can be monitored with just one analyzer. This approach is considerably more cost-effective when compared to the use of a dedicated analyzer in each room or other monitoring location.

For temporary use, G-SST vapor probes can be mounted on vertical stands or similar movable fixtures. This is ideal in a hospital or other office-type buildings where a permanent installation may not be appropriate.

Getting the Sterilant into the Room

It is also possible to fit the G-SST probe inside the HVAC system directly. By situating the probe immediately inline after the hydrogen peroxide generator, Sterilization Technicians will be able to directly monitor the concentration of Vaporized Hydrogen Peroxide or Ethylene Oxide gas as it is released into the room.

G-SST Probe installed in the HVAC system. Fiber Optic Cables connected to the probe are run to the HPV analyzer.

Monitoring the production of sterilant alongside the concentration achieved in each room or area, technicians can confirm that the complete sterilization system is functioning correctly.

The usefulness of monitoring Vaporized Hydrogen Peroxide in the HVAC duct system has been supported by the Department of Immunology, Max‐Planck Institute for Infection Biology, Germany, following a study in 2008. The study confirmed that: “VHP treatment [supplied by an HVAC system] is an effective means of reducing and eliminating room contaminations of M. tuberculosis.”

Why Monitor Sterilant Concentrations with NIR Spectroscopy?

Near-infrared spectroscopy is a means of sterilization monitoring that is functional in both a positive and negative atmosphere.

Electrochemical sensors are unable to operate in a vacuum and may be poisoned or otherwise damaged by high concentrations of sterilant. However, because NIR spectroscopy uses light to monitor chemical concentrations, a Vaporized Hydrogen Peroxide Analyzer can effectively monitor sterilant levels under non-condensing conditions.

The Hydrogen Peroxide Vapor Analyzer is a Hassle-Free Sterilant Monitor

An HPV analyzer will be calibrated at the factory where it is manufactured, meaning that no programming is needed from the user. Start-up simply involves providing power to the HPV analyzer, connecting the probe(s) via fiber optic cables and taking a ZERO reading in the dehumidified isolator. Once that has been done, H2O2 and H2O concentration measurements can commence.

This information has been sourced, reviewed and adapted from materials provided by Process Insights – Optical Absorption Spectroscopy.

For more information on this source, please visit Process Insights – Optical Absorption Spectroscopy.