Granular materials and fine powders are utilized widely in industrial applications. To optimize and control processing methods, these materials must be characterized accurately.

The characterization methods are related either to the properties of the grains (morphology, granulometry, chemical composition etc.) or to the behavior of the bulk powder (density, flowability, electrostatic properties, blend stability etc.). However, where the physical behavior of bulk powder is concerned, most of the methods used in R&D or quality control laboratories are based on old measurement techniques.

In the last 10 years, GranuTools modernized these techniques to meet the present needs of production departments and R&D laboratories. Specifically, the measurement processes have been automatized and rigorous initialization methods have been designed to gather interpretable and reproducible results.

Utilizing image analysis techniques improves the measurement’s precision. Numerous industries are already using the GranuTools instruments range in various fields, including:

- Additive manufacturing

- Bulk material handling

- Food processing

- Pharmaceuticals

This application note is chiefly centered on additive manufacturing.

Powder bed fusion (PBF) is a type of additive manufacturing process that includes Selective Laser Melting (SLM) and Selective Laser Sintering (SLS).

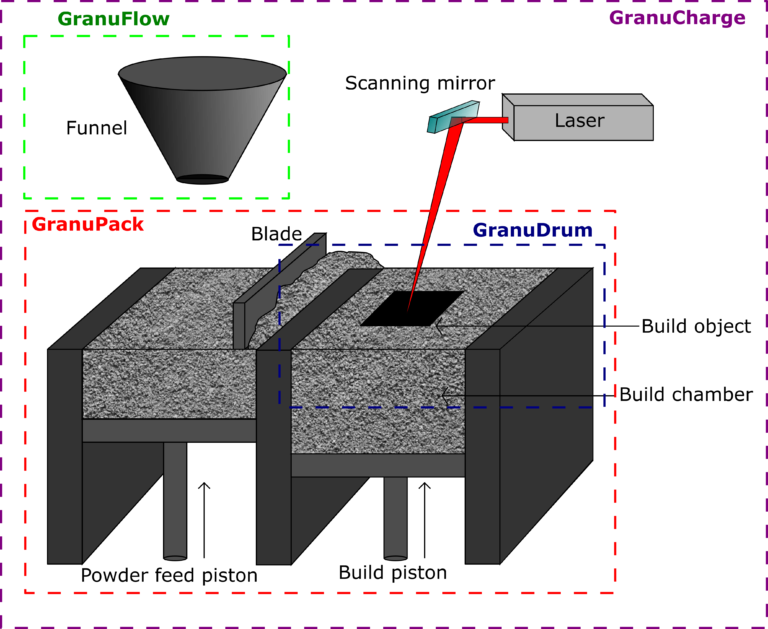

A schematic diagram of a standard laser PBF machine is described by the following figure (Figure 1).

Figure 1. Schematic diagram of a PBF process.

The powder is stored in a hopper and progressively exposed to the recoater by a rising piston. This recoater may be either a roller or a blade that spreads the exposed powder across the bed.

The core purpose of this process is to produce a uniform and stress-free thin layer. The powder excess is caught in a secondary container for re-use (recycling). The same cycle of spreading and melting is carried out several times to build the component layer-by-layer.

Inside the range of measurement methods developed by GranuTools, GranuDrum was selected for the present study due to its measured cohesive index, which has demonstrated the ability to quantify the spreadability of the powder throughout the recoating process (see reference G. Yablokova et al. 2015). The confining pressure is low, the flow speed is comparatively high and the free powder/gas interface plays a significant role in powder bed-based 3D printers.

Therefore, the cohesive index measured in the rotating drum geometry (explained in detail further on) is a suitable candidate to conduct powder rheology characterization in the framework of additive manufacturing.

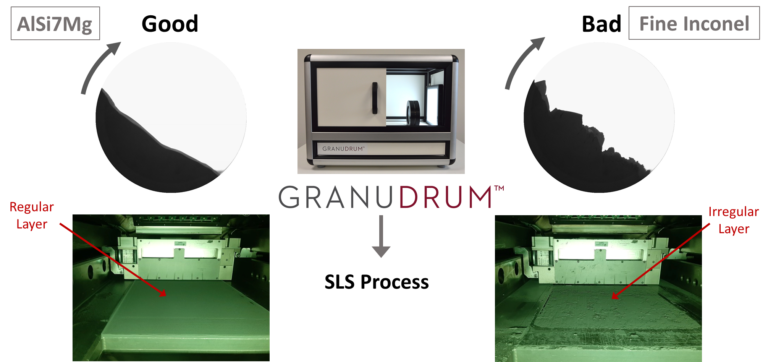

Figure 2 relates to GranuDrum measurement and the powder layer produced by the recoater. A good flowing powder (AlSi7Mg), which produces a homogeneous (regular) layer on the bed, also forms a smooth interface both in the GranuDrum and in the printer. However, powder with bad flowing properties, which creates a non-homogeneous layer on the bed, also forms an irregular interface in the GranuDrum.

Figure 2. A linkage between PBF recoating process and GranuDrum methodology (image analysis).

In the current application note, GranuDrum also allows the characterization of the powder recycling effect. Before showing and discussing the results, a detailed description of methodology and procedure adopted by GranuDrum is given in the next section.

Granudrum

The GranuDrum instrument is an automated powder flowability measurement technique founded on the rotating drum principle.

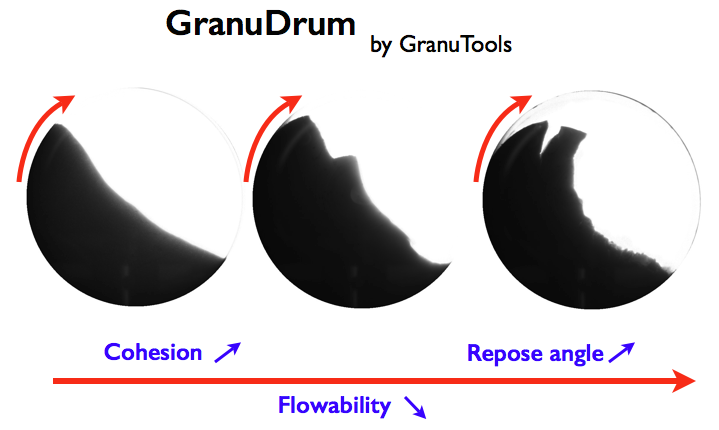

A horizontal cylinder with transparent sidewalls, called the drum, is filled halfway with the sample of powder. The drum rotates around its axis at an angular velocity ranging from 2 rpm to 70 rpm.

A CCD camera takes snapshots (10 to 100 images with intervals of 1s) for each angular velocity. The air/powder interface is detected on each snapshot with an edge detection algorithm.

Subsequently, the average interface position and the fluctuations around this average position are computed. Then, for each rotating speed, the flowing angle αf (also known as ‘dynamic angle of repose’ in the literature) is computed from the average interface position and the dynamic cohesive index σf is measured from the interface fluctuations.

Generally, a low value of the flowing angle αf correlates with good flowability. The flowing angle is impacted by a wide set of parameters: the shape of the grains, the friction between the grains and the cohesive forces (van der Waals, electrostatic and capillary forces) between the grains. The dynamic cohesive index σf is only related to the cohesive forces between the grains. A cohesive powder results in an intermitted flow whereas a non-cohesive powder results in a regular flow.

Figure 3. Sketch of GranuDrum measurement principle.

Therefore, a dynamic cohesive index closes to zero corresponds to a non-cohesive powder. When the powder cohesiveness rises, the cohesive index rises accordingly.

In addition to the measurement of both the cohesive index σf and the flowing angle αf as a function of the rotating speed, GranuDrum enables the measurement of the first avalanche angle and the powder aeration during the flow.

The cohesive index is the focus in this application note.

Powders Description

Titanium-based metal powder (Ti6-Al4-V) was utilized for this investigation. Two different states of this powder were employed: fresh and recycled (multiple stages). The following table summarizes the information about particle size distribution.

Table 1.

| Powder Name |

Particle Size |

| Ti6-Al4-V(fresh) |

d10=15 µm, d90=53 µm |

| Ti6-Al4-V(recycled) |

d10=20 µm, d90=63 µm |

All those products will be investigated via the GranuDrum standard cell (cell volume=100 ml; volume of powder used=50 ml).

Process Description

The two powders shown above are notable, as they perform well in the process (Selective Laser Sintering: SLS). However, they vary a little in some features. For fresh Ti6-Al4-V powder, it was necessary to keep dosing setting (amount of powder) higher on the bed in comparison to the recycled (reused) powder. Because of the qualitative nature of the observations on recoating, it was proposed to reach out about the GranuDrum analysis. This was in order to learn if quantitative values could be determined and provide an explanation to the observations.

Granudrum Analysis

Experimental Protocol

For an experiment with the GranuDrum, powders were poured inside the measuring cell just after box opening. The amount of powder used was 50 ml. Each powder was analyzed under ambient conditions (40±1%RH and 20±1°C). GranuDrum velocities were investigated from 2 to 60 rpm. For each velocity, 40 pictures were taken to strengthen the precision and repeatability of measurement.

Experimental Results

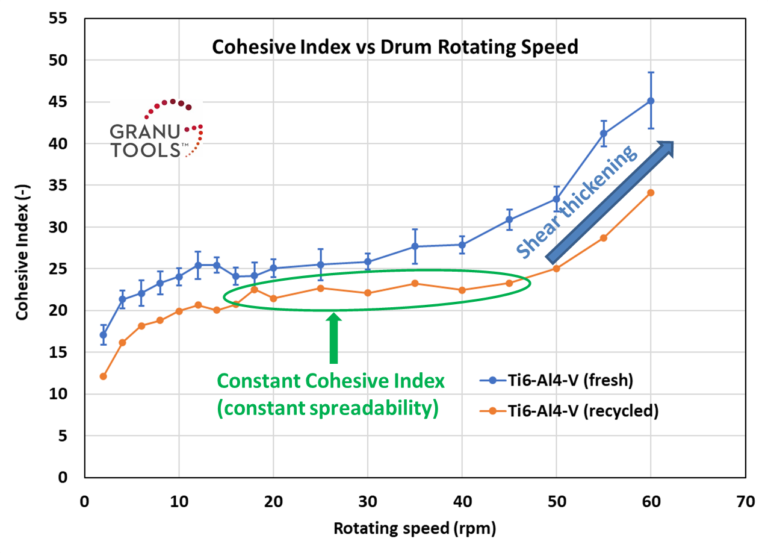

Figure 4 presents the Cohesive Index as a function of the GranuDrum rotating speed. Cohesive Index is linked to the fluctuations of the interface (powder/air) position induced by cohesive forces (Van der Waals, Electrostatic and Capillary). Therefore, as discussed in the Generalities section, it quantifies powder spreadability.

Figure 4. Cohesive Index versus Rotating drum speed for metal powder.

Fresh powder, which has a higher cohesive index, was measured three times to see the reproducibility of the result. Error bars are showing the standard deviation with respect to the average value.

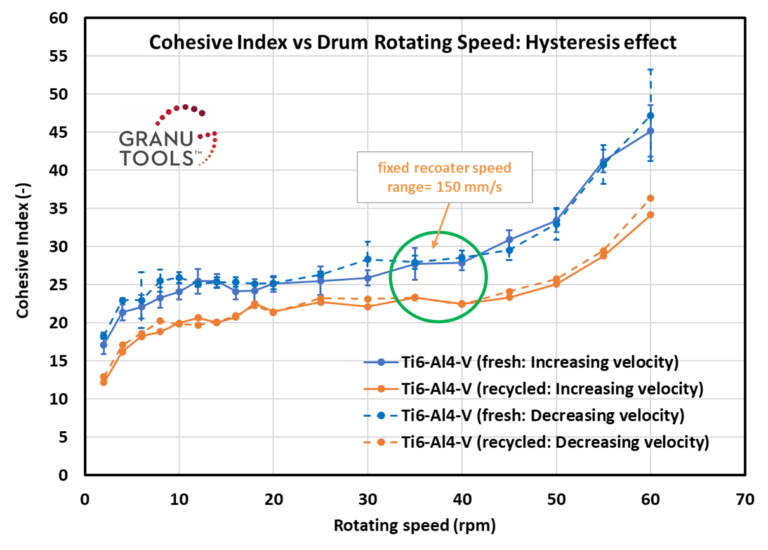

In Figure 5, the decreasing rotating speed is also presented to check the existence of hysteresis.

Figure 5. Cohesive Index versus Rotating drum speed for metal powder: hysteresis effect.

Discussion

Globally, recycled powder has a lower cohesive index i.e. better spreadability than the fresh powder. The recycled powder formed by larger particles (due to the loss of fine particle during recycling) is noted to be particularly less cohesive.

The relation between Dynamic Cohesive Index and drum rotating speed is explicitly shown in figure 4 for both samples (Ti6-Al4-V: fresh and recycled). Analyzing these curves allows shear-thinning/shear-thickening to be characterized.

Both powders exhibit shear thickening behavior. This behavior provides an explanation for how cohesive index increases with the speed and it helps to set the optimum recoater speed.

The default recoater speed was set to 150 mm/s (corresponding to 35 rpm of the rotating drum) suggested by the printer manufacturer. GranuDrum also confirms that this speed has a good recoat overall for the builds regardless of fresh and recycled powder.

This analysis of cohesive index make sense for given SLS process. It was observed that fresh Ti6-Al4-V powder was sticking inside the funnel during feeding and as well as on the recoater during spreading. In addition, irregular surface was formed on the bed. Therefore, higher dose setting, and more process time was required by the recoater (higher cohesion confirmed by GranuDrum) to form a homogeneous layer and better piece of an object.

However, the recycled powder was properly fed inside the funnel and formed a homogeneous layer on the bed without sticking on the recoater blade (lower cohesive index confirmed by GranuDrum). Therefore, a low dose of the recycled powder was required at the feeding stage. In the GranuDrum, recycled powder stays in a flatter region longer over rotation speed in the 18-45 rpm range. Therefore, more room for the speed optimization was achieved for this specific powder.

There was no evidence of agglomeration during the printing process. This corresponds with the hysteresis measurement of GranuDrum (Figure 5). If powder follows an identical trend while increasing (2-60 rpm) and decreasing (60-2 rpm) rotating speed, the hysteresis effect does not exist. This effect is not a major factor for any of the powder under consideration, which relates to the behavior of the powder (no agglomeration) during the process.

Conclusions

- The effect of recycling on the spreadability of Titanium metal powder (Ti6-Al4-V) utilized in SLS process is investigated with the cohesive index measured by GranuDrum.

- The measurements display substantial variations between fresh and recycled powder.

- Recycled powder has lower cohesive index in comparison to fresh powder. Therefore, the spreadability of recycled powder is better, as can be seen in the printing process. The bigger average particle size of recycled powder (due to the loss of fine particle during recycling) is coherent with this cohesiveness decrease.

- GranuDrum follows the evolution of powder rheological characteristics during the repeated recycling process in the framework of additive manufacturing applications.

References and Further Reading

- How to gain a full understanding of powder flow properties, and benefits of doing so, G. Lumay, N.M. Tripathi, F. Francqui, ONdrugDelivery Magazine, 102, 42-46 (2019).

- The influence of powder characteristics on processability in metal additive manufacturing, D. Whittaker, EuroPM Congress and Exhibition, 4(4), 147-158 (2018).

- Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

- Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

- How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

- Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

- Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

- Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

- Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

- Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

- Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewalle, Powder Technology 224, 19-27 (2012).

- Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

- Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

- Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

- Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

- Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

- Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

- The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

- The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).

- Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

- Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

- Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

This information has been sourced, reviewed and adapted from materials provided by Granutools.

For more information on this source, please visit Granutools.