A number of refineries utilize a combination of technologies to effectively measure and enhance the distillation of crude oil into isolated hydrocarbon components, in order for them to be processed into higher-value products.

A frequently used solution to guarantee the quality of products is to use more effective analyzers that complete atmospheric distillation that complies with ASTM D86.

In 2017, ASTM D4814 Standard Specification for Automotive Spark-Ignition Engine Fuel, listed ASTM D7345 (Micro Distillation Method) as an approved alternative technique for distillation of gasoline. The result is that micro distillation analyzers are also an approved technique for the determination of distillation characteristics for gasoline.

The approval of alternative procedures of distillation measurement provides a monumental opportunity to integrate efficiencies into the process of distillation for gasoline, diesel, and jet fuel applications.

Traditionally, this is a slow-changing industry. For example, refining, operators, and stakeholders must have proof and quantified data to be certain that novel technologies like micro distillation analyzers will provide true physical distillation that corresponds with traditional distillation analyzers prior to adopting the micro distillation technique into their process.

PAC completed a sequence of tests that demonstrated how successfully micro distillation analyzers correlate with D86-compliant analyzers. PAC is a principal manufacturer of lab and process analyzers, inclusive of Herzog and ISL brands.

A Comparison of Three Unique Distillation Analyzers

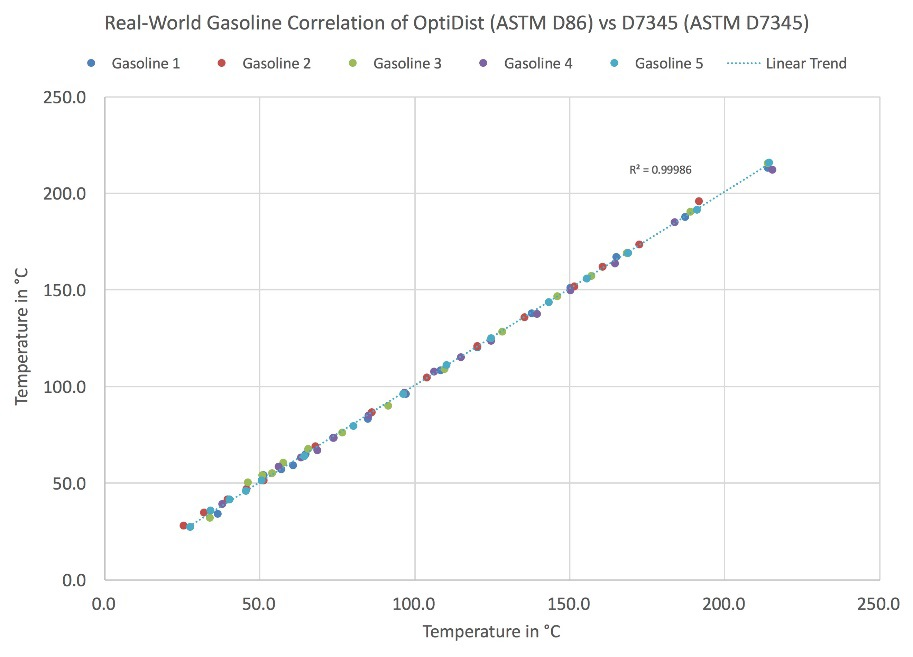

In partnership with a large group of refineries worldwide, PAC completed a sequence of tests comparing its three unique distillation analyzers. Throughout the duration of testing, five unique gasoline samples were run through each of the distillation analyzers, showing high levels of correlation between the two micro distillation analyzers, MicroDist and PMD 110, the precursor of the novel OptiPMD, utilizing the ASTM D7345 technique, and the laboratory distillation analyzer, OptiDist, which uses the ASTM D86 technique.

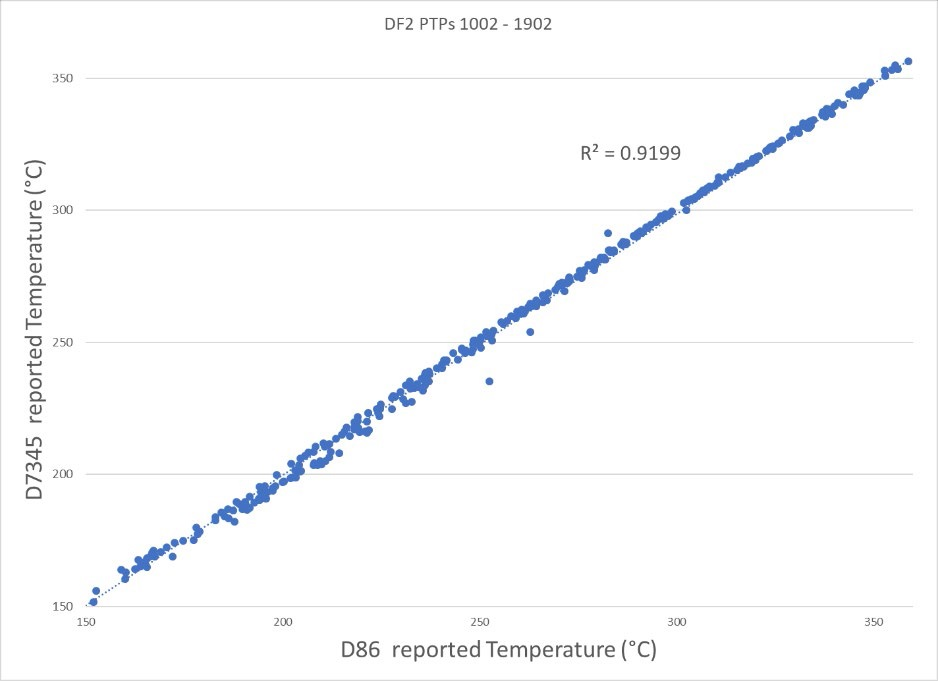

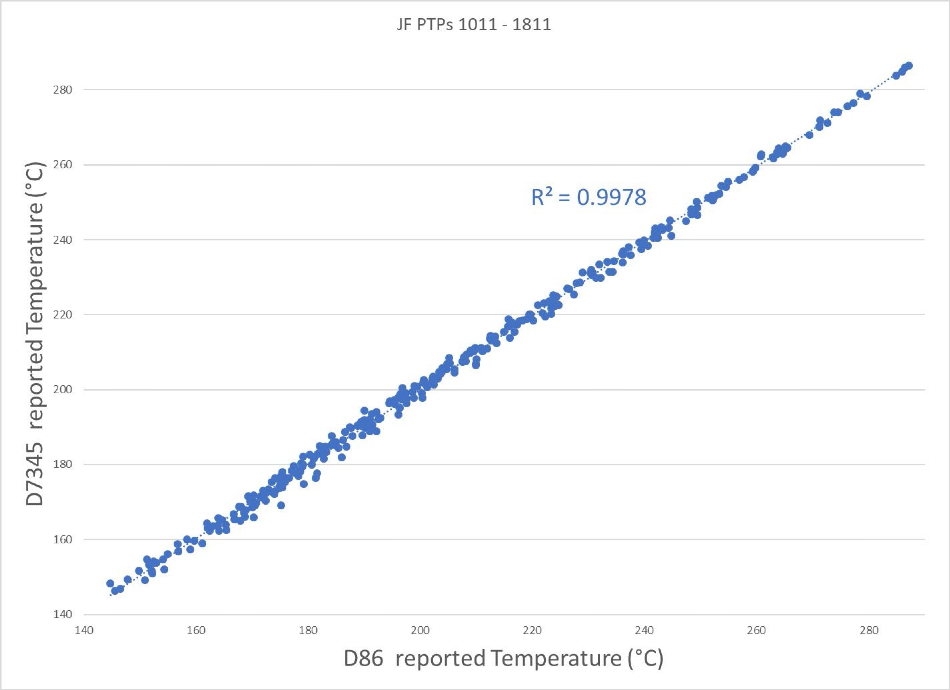

A second study was conducted on the basis of documentary research of numerous Proficiency Testing Programs (PTP) from ASTM making comparisons of the whole boiling point range from labs reporting D86 or D7345 for samples of #2 Diesel and Jet Fuel. PTPs for #2 Diesel (DF2) consisted of 28 reports released between June 2010 and February 2019. PTPs for Jet Fuel (JF) consisted of 25 reports released between November 2010 and November 2018.1

OptiDist

OptiDist is an automated atmospheric distillation analyzer that offers a 35 minute cycle time, with full compliance with all atmospheric distillation methods, including ASTM D86. It is created to accommodate multi-methods and non-standard capabilities and can be modified for numerous applications.

As an extremely user-friendly tool, there is potential for installation of the flask in seconds with just one hand and testing initiation is completed at the push of a button. OptiDist is field-proven in delivering up to two times better precision for all common distillation samples.

OptiPMD

OptiPMD is a micro distillation analyzer with a 10 minute cycle time with full compliance with ASTM D7345 and results can be reported as equivalent to ASTM D86, ASTM D1160, ISO 3405, and IP 123. It is a compact, portable design resulting in it being perfect for field use. With true physical distillation taking 10 minutes, the boiling range characteristics of any commercially available petroleum product from a 10 mL sample can be accurately determined.

OptiPMD needs zero pre-testing or programming and provides remarkably quick results and validation utilizing user-defined criteria and pass/fail notifications that are automatic. Method D7345 is recognized as a substitute for D86 and D1160 tests in 10 ASTM specifications and in over 10 fuel specifications around the world.

MicroDist

MicroDist is an online micro distillation analyzer which functions in full compliance with ASTM D7345. It has a 10 minute cycle time and capabilities for automatic pull samples from the pipeline. Additionally, it fully correlates with ASTM D86, ISO 3405, IP 123, and Cetane Index in accordance to ASTM D4737 and ASTM D976 (procedures A & B).

Test results from MicroDist are provided with less variability, enabling enhanced control and maximum upgrade from low- to high-value products. With complete automation of initial heat, distillation rate, and final heat regulation, MicroDist provides robust and reliable process control.

Results

The test results concerning five unique gasoline samples showed an exceptional correlation between ASTM D86 and ASTM D7345, as demonstrated below.

Illustration 1. PAC measured five different gasoline samples at temperatures ranging from 25 °C to 220 °C. At every stage of the testing process, the results demonstrated excellent correlation between the online micro distillation analyzer, MicroDist, to the laboratory distillation analyzer, OptiDist. (R squared of 0.9999).

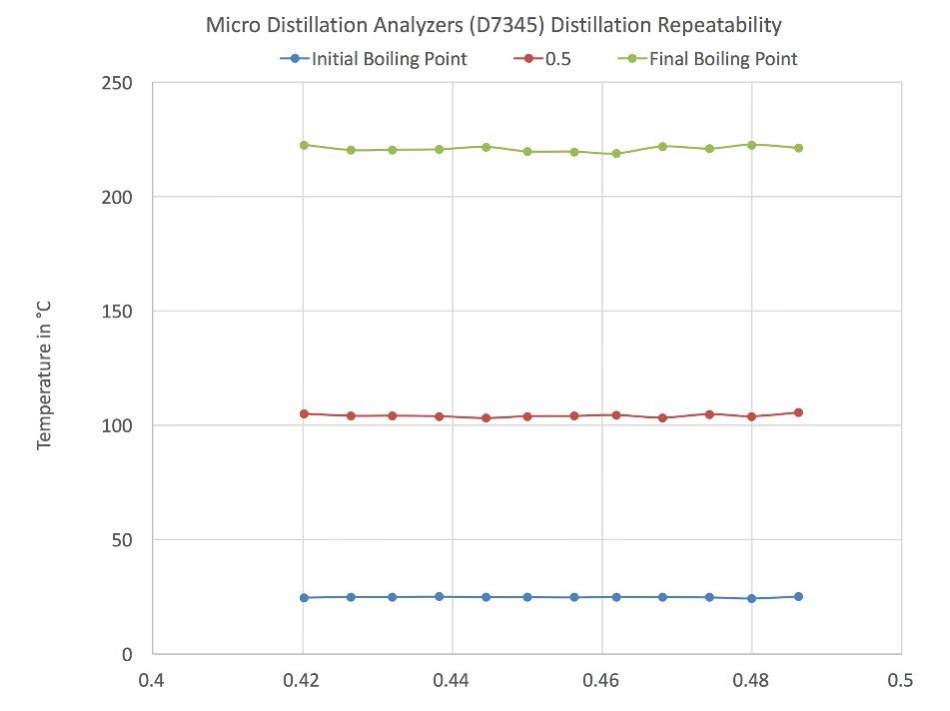

Illustration 2. The tests also showed very high repeatability of micro distillation analyzers for a typical gasoline sample.

The documentary research based on #2 Diesel and Jet Fuel PTPs verifies there is an excellent correlation between the boiling temperatures gained by both D86 and D73451.

Illustration 3. Tests under reproducibility conditions, such as those found in PTPs, encompassing multiple samples over a 9-year period, and a wide range of temperatures also demonstrate an excellent correlation between methods.

Illustration 4. The excellent correlation already proved for gasoline and diesel samples also apply to other fuels such as Jet Fuel, demonstrating why D7345 is accepted globally as an alternative to D86.

Conclusion

Analyzers utilizing both the ASTM D86 and ASTM D7345 methods have been proven to provide reliable, highly correlated outcomes. The superior selection of analyzers is mainly dependent on the needs of the refinery.

Laboratory distillation analyzers using the D86 method, such as OptiDist, are perfect for laboratory analysis when full compliance with all atmospheric distillation methods is needed. OptiDist is extremely versatile making it easy to modify the tool for several different applications.

Micro distillation analyzers like OptiPMD and MicroDist are perfect for field analysis, particularly for gasoline, diesel, and jet fuel applications. Due to numerous fuel specifications being published, not only by ASTM, but also in several countries, and allowing analysis via the alternate method D7345, the OptiPMD and MicroDist can be utilized to release products to specifications without the requirement of further laboratory testing.

References and Further Reading

1. DF2 and JF data courtesy of ASTM Proficiency Testing Program

This information has been sourced, reviewed and adapted from materials provided by PAC L.P.

For more information on this source, please visit PAC L.P.