Key Issues

• Results from in situ Raman spectroscopy in agreement with off-line XRD

• In situ crystallization monitoring

Introduction

A number of materials can crystallize in forms known as polymorphs, with these forms differing in the crystal lattice’s three-dimensional arrangement of molecules or atoms.

Polymorphs tend to possess very different physical properties, regardless of their chemical similarity. As such, their crystallization should be carried out in a controlled manner in order to yield the correct form.

This process requires an effective method for monitoring the crystals in situ. Raman spectroscopy provides an ideal solution for quickly distinguishing different polymorphs, because differences are generally traceable by the appearance or disappearance of characteristic Raman bands, or via a shift in their wave-number positions.

It is possible to use Raman spectroscopy with either an in situ immersion probe or a non-contact probe, depending on the specific application’s requirements. Furthermore, Raman spectroscopy is non-destructive, and requires no sample preparation.

This article explores the use of Raman spectroscopy for monitoring the selective crystallization of polymorphs of Calcium Carbonate (CaCO3), occurring in the presence of polymeric additives (Table 1). The three polymorphs of CaCO3 used within this application are calcite (rhombohedral), vaterite (hexagonal), and aragonite (orthorhombic), in descending order of their thermal stability.

Table 1. Polymeric Additives Used in This Work. Source: Kaiser Optical Systems, Inc.

| Polymeric Additive |

Abbreviation |

| Acusol® |

|

| Poly(aspartic acid) |

PAspAcid |

| Poly(acrylic acid) |

PAA |

Polymaleimide synthesized

by KOH initiator |

PMI_KOH |

Polymaleimide synthesized

by PbO and t-butyl benzyl

alcohol initiator |

PMI_PbO |

Polymaleimide synthesized

by bis(triphenylphosphine)

Cu(I) nitrate and t-butyl

benzyl alcohol initiator |

PMI_Cu_sys |

Experiment

Crystallizations occurred in a Sodium Carbonate (Na2CO3) solution (500 mL, 1000 ppm of carbonate) with polymeric additive (1.4 ppm). The process was completed in an automated laboratory reactor at 25 °C.

A Calcium Chloride (CaCl2) solution (54 mL, 6250 ppm) was added to the reaction solution at a rate of 1 mL every 5 minutes, with the reactor stirring the mixture at 400 rpm. A Kaiser Raman analyzer operating at 785 nm with a 785 nm Invictus™ laser was employed to collect Raman spectra every 10 minutes.

Results from Raman spectroscopy were then verified using x-ray diffraction (XRD) on grab samples.

Calibration

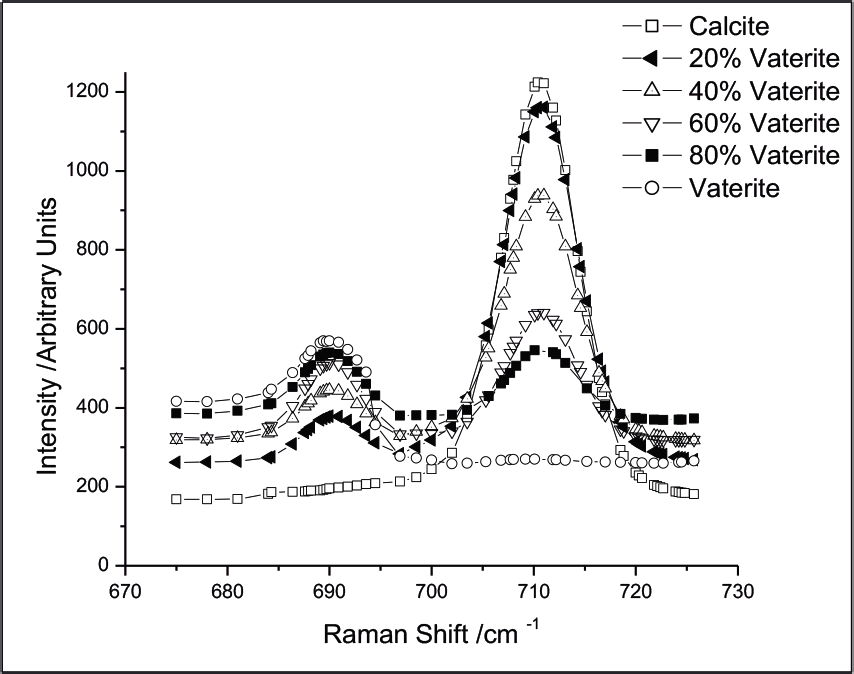

Peak intensity ratios were used to calibrate both the Raman spectra and XRD data. For the Raman spectra, peaks that corresponded to the carbonate plane bending modes of vaterite (690 cm–1) and calcite (711 cm–1) were utilized,1 because Aragonite is only formed at temperatures higher than 90 °C. Results of this calibration are displayed in Figure 1.

Figure 1. Raman spectra of prepared mixtures of CaCO3 polymorphs. The intensities of the bands at 690 and 711 cm–1 vary with the concentration of calcite and vaterite, respectively. Image Credit: Reprinted with permission from Ref. 1. Copyright © 2003 American Chemical Society.

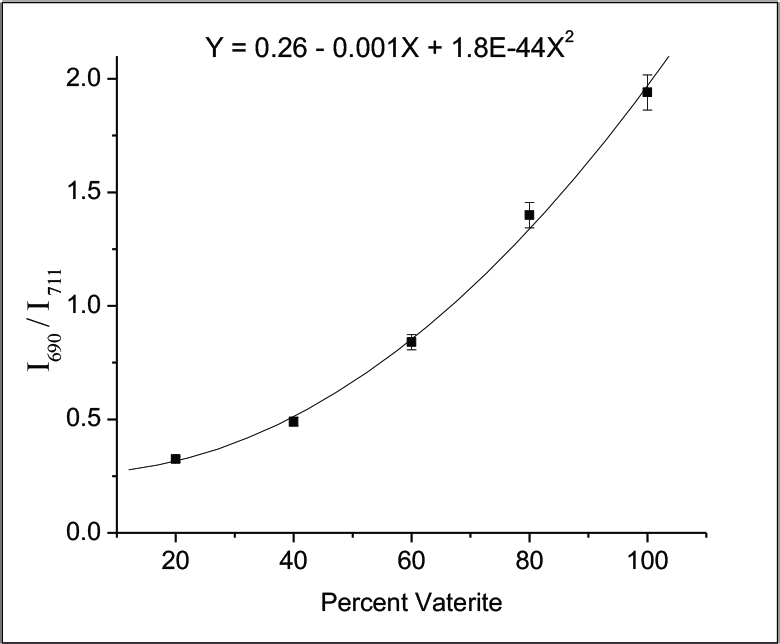

Peak intensities from known concentrations of calcite and vaterite were ratioed to construct a calibration curve. Data was then fitted to a second-order polynomial to acquire the calibration equation (Figure 2).

Figure 2. Calibration curve obtained by ratioing the 690 and 711 cm–1 Raman bands. Image Credit: Reprinted with permission from Ref. 1. Copyright © 2003 American Chemical Society.

Results

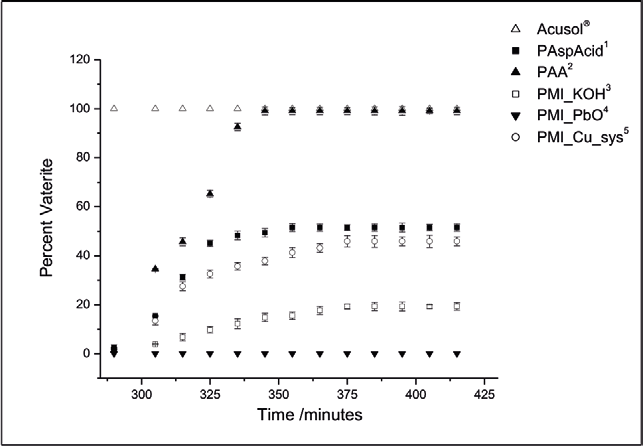

Figure 3 displays the results from the experiments. It was observed that PMI_PbO did not affect the phase equilibrium at all, while two other polymeric additives - Acusol® and poly(acrylic acid) - led primarily to vaterite.

Figure 3. Percent vaterite during the course of the experiments, as determined by Raman spectroscopy. Image Credit: Reprinted with permission from Ref. 1. Copyright © 2003 American Chemical Society.

In the case of the experiment with Acusol®, calcite appears to have never formed in the solution, while with poly(acrylic acid), vaterite is preferentially formed over the course of the crystallization. With PMI_Cu_sys, however, vaterite is never formed.

Other polymeric additives provided results which existed between these extremes, only moderately affecting the phase equilibrium. The analyzer’s axial transmissive spectrograph design meant that the whole spectrum could be collected simultaneously, rather than using successive scans across sections of the spectral range.

This feature was highly important since the reaction mixture is heterogeneous and was being rapidly stirred, meaning that scanning would result in differing regions of a spectrum being collected from several different materials as they move through the probe’s focal cylinder.

Conclusion

Results ascertained via Raman spectroscopy and by XRD were found to agree to within 2 %, confirming that Raman spectroscopy is a convenient and effective alternative to other, more traditional methods of polymorph determination. This agreement also verifies that particle size had no effect on the quantification.

Raman spectroscopy has excellent potential for use as an on-line control method for polymorph identification during crystallization, while possessing the chemical specificity to improve process understanding (for example, by identifying new polymorphs or intermediates) throughout the reaction monitoring, optimization and scale-up stages of drug substance development.

References

- Agarwal, P. and Berglund, K.A. “In Situ Monitoring of Calcium Carbonate Polymorphs during Batch Crystallization in the Presence of Polymeric Additives Using Raman Spectroscopy” Crystal Growth & Design, Vol. 3, Issue 6, 2003, 941.

*Acusol is a registered trademark of Rohm and Haas Company

This information has been sourced, reviewed and adapted from materials provided by Kaiser Optical Systems, Inc..

For more information on this source, please visit Kaiser Optical Systems, Inc..