A processing stage that involves a molten state, commonly known as melt, is required in order to convert polymers from raw materials into the final product. After cooling, the final product will usually be in a semi-crystalline state.

Developing at the point of solidification, the nanostructure of this semi-crystalline state affects the mechanical and physical properties of the polymer product significantly. Therefore, it is crucial to study and define the crystallinity for industrial R&D and process optimization in addition to fundamental studies.

In the experiment below, wide-angle X-ray scattering (WAXS) measurements were performed on isotactic polypropylene (i-PP), using a temperature control stage from Linkam.

Measurements and Results

To enclose an i-PP pellet, a thin aluminum foil is utilized (from Innovia Films, U.K.) to stop any direct air exposure and guarantee good thermal contact. Subsequently, the polymer sample was mounted and fixed into the temperature control stage (Linkam HFSX350).

The crystallization of the i-PP pellet was measured in real-time by the WAXS configuration of the Xeuss 2.0 SAXS/WAXS system. A quenching experiment at 148 °C from the fully molten state was performed, with an exposure time of 200 seconds.

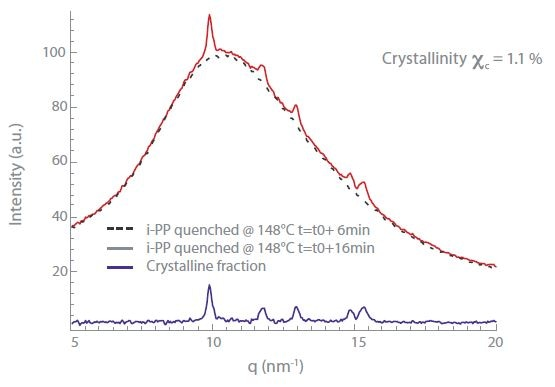

Figure 1 shows the single-dimensional scattering curves and the corresponding analysis of the crystalline and amorphous fraction of the sample 16 minutes after the quench. The ratio of the integrals of the crystallized and amorphous curves is employed to calculate the crystallinity, as elaborated by Panine et al1.

It is possible to study low levels of crystallinity even during real-time crystallization, as the Xeuss SAXS/WAXS system has a negligible signal-to-noise ratio. So, as depicted in Figure 1, crystallinity levels well below 5 %2 can be determined. Here, the crystallinity is estimated at 1.1 %.

Figure 1. 1D scattering curves and estimation of a crystalline fraction.

Simultaneous SAXS and WAXS Measurements

The physical and mechanical properties of the solid polymer result from its crystallization kinetics, which affects both the nanoscale structure and the level of crystallinity.

The crystallographic order can be described by short length scale measurements (WAXS); while characterization at long length scales (SAXS investigation) supplies information regarding the morphology of the crystalline phase.

In order to gain a better understanding of the underlying processes, it is crucial to study evolution as a function of temperature at both length scales at the same time. Such simultaneous SAXS/WAXS measurement capability is supplied by the Xeuss SAXS/WAXS system.

References and Further Reading

- Panine et al, Polymer, 2008, 49, 676-680

- Wang et al, Macromolecules, 2000, 33, 978-989

This information has been sourced, reviewed and adapted from materials provided by Xenocs.

For more information on this source, please visit Xenocs.