Size distributions of nanoparticles which are utilized for process monitoring or quality assessment have been established in a number of forms. Nanoparticles are being created at a growing rate and have become a vital building block for the development of new materials with enhanced properties.

In addition to the chemical nature of the nanoparticles, the performance of the final products is dependent on their size, and on their ability to maintain a dispersed state throughout the processing stages.1

Small Angle X-ray Scattering (SAXS) is a non-destructive technique with minimal sample preparation, which enables the determination of material structure in the range 1-250 nm. It gives statistically relevant information over a large volume (usually 1 mm3). Therefore, it is the perfect complement to microscopy techniques that only supply local information.

While traditionally SAXS is used for narrow size distributions on well-defined laboratory batches, this article demonstrates how coupled with a unique data analysis algorithm, SAXS can be applied successfully to industrial batches of nanoparticles at multiple process steps.

Nanomakers is a manufacturer of nanocomposites and nanosized particles.2 SAXS is the only technique that allows precise nanoscale size determination of dry powders, dispersions, and nanocomposites, supplying Nanomakers with nanostructural information throughout the entire production chain.

Measurements and Results

A batch of SiC powder produced by Nanomakers (modal size 33.5 nm according to transmission electron microscopy) has been characterized in three different forms: as a nanocomposite, as a dry powder, and as a dispersion (using ISO Methodology3 for characterizing the dispersions) by utilizing the Nano-inXider.

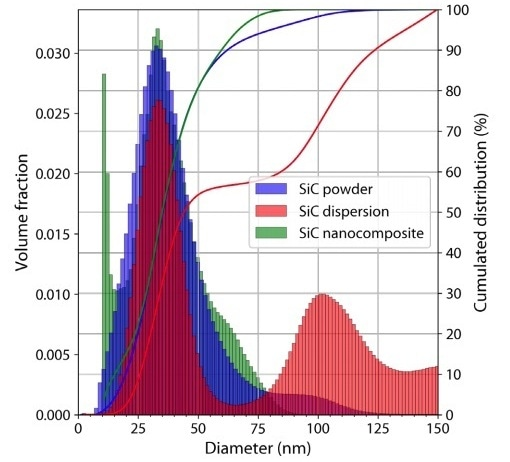

Figure 1. Particle size distributions obtained by SAXS on the SiC nanoparticles measured as a dry powder, as a dispersion or as a nanocomposite. The solid lines correspond to the cumulated volume fraction. The bin width for the histograms is 1.4 nm.

After data reduction, the experimental scattering profiles were fitted by using the Expectation-Maximization algorithm (EM),4,5 implemented in the Xenocs XSACT software to determine the size distribution of the nanoparticles.

Figure 1 shows the size distributions that were determined from SAXS data. The modal size of the primary SiC nanoparticles has been detected properly on all the samples, with a size resolution of 1.4 nm.

While most of the SiC nanoparticles are well-dispersed, SAXS has determined the presence of residual agglomerates in the dispersion. On the size distribution of the nanocomposite, the SiC mode around 35 nm can be seen, though the polymer matrix contributes with a sharp mode around 5 nm.

This determines the good dispersion state of the nanoparticles in the polymer matrix. With minimal effort and time compared to other characterization methods, this data confirms the powder synthesis and processing steps used by Nanomakers.

Conclusion

SAXS associated with the EM algorithm can determine the size distributions of industrial-grade nanoparticles measured as dry powders, dispersions, or embedded in a matrix accurately. The minimal sample preparation and short measurement times are compatible with the needs of process monitoring and routine assessment.

SAXS is a relevant and powerful technique that is complementary to electron microscopy. The Xenocs XSACT software integrates state-of-the-art SAXS algorithms and greatly simplifies data analysis.

References and Further Reading

- S. Logothetidis, “Nanostructured Materials and Their Applications”, NanoScience and Technology, 2012.

- https://www.nanomakers.com

- Particle size analysis - Small-angle X-ray scattering. ISO 17867:2015, 2015.

- F. Benvenuto, H. Haddar, and B. Lantz, SIAM Journal on Applied Mathematics, 2016, 76 (1), pp.276-292.

- M. Bakry, H. Haddar, O. Bunau, J. Appl. Cryst. (2019). 52, 926-936

This information has been sourced, reviewed and adapted from materials provided by Xenocs.

For more information on this source, please visit Xenocs.