In this interview, AZoM talks to Dr. André Wutzler, a scientist in the field of Plastics Analysis and Plastics Technology at Polymer Service GmbH Merseburg, about how he is using DMA to conduct his research.

Can you give a brief overview of the Polymer Service GmbH Merseburg and the work you do?

I work in the fields of plastics characterization and plastics processing with a focus on thermal analysis, spectroscopy, and extrusion. I help our customers to understand the structure-property relationships, in order to optimize production processes and products with over 30 years of professional experience.

We also offer a broad portfolio of scientific services in the area of polymer materials and polymer technologies. This ranges from polymer synthesis to polymer processing, and polymer testing to damage analysis by experts.

The Polymer Service GmbH Merseburg (PSM) itself was established in 2001 as an associated institute at the Martin Luther University Halle-Wittenberg. In 2014, the company became an associated institute at the University of Applied Science in Merseburg. Today, 70% of PSMs 30 employees are either scientists or engineers.

What are the biggest industries that you are testing materials for?

The largest sectors are polymer manufacturers, the household appliance industry, and of course, the automotive industry. In addition to this, engineering offices are also some of our regular customers with the question of material characteristics for both modeling and simulation.

You are offering several testing techniques for polymer analysis. Please tell us what you usually test and find out with “dynamic mechanical analysis”?

The Dynamic Mechanical Analysis (DMA) has two main tasks. On the one hand, it is the determination of the temperature and frequency-dependent stiffness. Whereas on the other hand, it is the determination of the glass transition temperature.

This temperature characterizes the transition between brittle and ductile material behavior. A glass transition temperature is also an important tool for evaluating the compatibility between polymers.

Since many plastic products today often consist of mixtures of at least two polymers, knowledge of the compatibility of the blend partners and their affinity to one another is of crucial importance. In the case of three-dimensionally crosslinked polymers such as rubber or resins, the DMA provides easy access to the mean network chain length (such as the “distance” between two network points). The DMA is therefore very well suited to checking the quality of the crosslinking reaction in this area.

What role does Anton Paar play in your work?

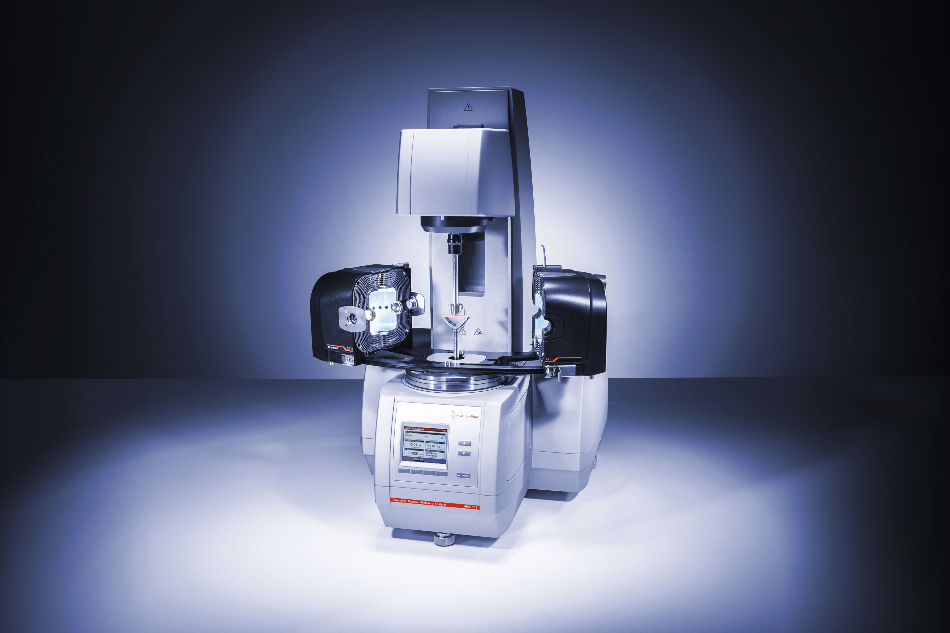

We cover around 70% of our service and research tasks in the DMA area with the MCR 702 MultiDrive from Anton Paar.

What functions of the Anton Paar instrument made you want to use it?

When the decision was made in 2010 to buy a new torsion DMA measuring station, the decision was not difficult. The main argument for AP as the supplier of the new measuring station was the high flexibility of their systems. With the appropriate choice of oven and sample tool, almost all applications are possible in which the samples are loaded in rotation (either uniform or oscillatory).

Are there any other benefits to using Anton Paar as a partner?

We had a very good relationship with our customer service representative and with the application specialists in the office right from the very beginning. We spoke the same language and it was not difficult to implement our wishes for an optimal measuring station in hardware.

In recent years, AP has also come to appreciate the expertise of PSM in the area of DMA. We were able to give some important impulses for the further development of hardware and software in this area.

What does the future hold for the Polymer Service GmbH Merseburg?

We have established ourselves well in the market for non-university testing institutes. Our customers appreciate both the competence and the short processing times for their projects in-house. This is a very important point, especially for questions relevant to the market from the industry.

We would like to consolidate and expand this position in the future. Together with the University of Applied Science Merseburg, we are continuing to work on training plastics specialists for industry. The move to a modern research building is a very big goal for the near future in this context.

I hope that future cooperation with AP will continue to be as intensive as it has been so far. There may also be an opportunity for collaboration beyond DMA.

About Dr. André Wutzler

Dr. Wutzler was born in 1965 and did his high school diploma in 1984 at the special school for chemistry at the Technical-University Leuna-Merseburg. He began studying physics there in 1986, and graduated in 1991 with a degree in physics. After, he worked at various different institutes at the Martin-Luther-University Halle-Wittenberg. He graduated with a doctorate in engineering sciences in 2001.

Dr. Wutzler was born in 1965 and did his high school diploma in 1984 at the special school for chemistry at the Technical-University Leuna-Merseburg. He began studying physics there in 1986, and graduated in 1991 with a degree in physics. After, he worked at various different institutes at the Martin-Luther-University Halle-Wittenberg. He graduated with a doctorate in engineering sciences in 2001.

He has been working at Polymerservice GmbH Merseburg since 2004. He works in the business area of Plastics Analysis and Plastics Technology.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.