For over fifteen years, aircraft manufacturers have utilized thermoplastic composites for their toughness and durability as a structural composite. Aerospace design allowable databases are available for applications in both commerce and the military.

Most of the volume applications reside in the commercial realm where structural applications vary from engine pylon doors to leading edges to beams and brackets. Applications are as far-ranging as overhead bins and interior galleys, to sound suppression systems on aircraft engine nacelles.

Image Credit: Toray Advanced Composites

OEMs have shown an increased interest in thermoplastics recently. While a range of reasons exists for choosing a thermoplastic composite, a number of key requirements are fueling this trend.

Firstly, thermoplastic structures with very low void content can be produced without using an autoclave due to automation solutions and the production of very low void thermoplastic unitapes.

Part and equipment suppliers like Automated Dynamics, ACM/Experion, Fiberforge, and Cutting Dynamics have produced unique machine technologies to optimize the fabrication of thermoplastic composite parts.

Secondly, as thermoplastics have the ability to be fusion welded through induction or resistance welding methods, this presents an effective means to decrease weight and cost through the elimination of fasteners.

Gulfstream through Fokker Aerostructures used induction welding to produce the tail assembly for the G650 business jet. The structure attained a 20% cost reduction and 10% weight savings compared to a thermoset composite structure.

Lastly, the change to composite fuselages leads to the removal of metallic structural brackets and the corresponding impact of galvanic corrosion. Thermoplastic composites offer superior fire retardancy and structural characteristics. Thermoplastics also introduce cost-effective techniques (thermoforming or compression molding) for the production of the various metallic brackets.

The majority of new automation solutions demand low void content thermoplastic prepreg materials and very high consistency. Low void content tapes are beneficial in efficient fabrication automation tape solutions. Starting materials with an inherently low void content and a well-impregnated tow are favored in this process.

This article outlines the material forms and materials utilized in aerospace today, with a focus on the fabrication techniques being employed.

Polymer Technology

Semi‐crystalline and amorphous are the two types of thermoplastic polymers.

No crystalline structure is formed by amorphous thermoplastics. Below the glass transition temperature (Tg), the polymer molecules are solids. The polymers can be molded at temperatures above the Tg as there is sufficient energy for the molecules to move in relation to each other.

Amorphous thermoplastic polymers can normally be molded at temperatures that are nearer to their Tg compared to semi‐crystalline polymers. The one limitation of amorphous thermoplastics is that they can exhibit poor resistance to particular solvents.

A semi‐crystalline polymer has regions where it is amorphous and regions where the polymer is closely packed together in a crystal lattice. The cooling rate adopted during part formation and the polymer type both influence the degree of crystallinity in the individual part.

Semi‐crystalline polymers have a melt temperature (Tm) and a Tg where the amorphous phase has sufficient energy to begin moving. The melt temperature is the temperature at which the crystalline structure deteriorates.

At present, the primary thermoplastics employed in composites include:

- Poly‐ether‐ketone‐ketone (PEKK) – Semi‐Crystalline

- Poly‐ether‐ether‐ketone (PEEK) – Semi‐Crystalline

- Poly‐phenylene‐sulfide (PPS) – Semi‐Crystalline

- Nylons-Amorphous or Semi‐Crystalline

- Poly-ether‐imide (PEI) ‐ Amorphous

Material Forms

Material forms in thermoplastics are available in three types. The first category is the fabric prepregs utilizing a common glass fiber woven or carbon material with a thermoplastic resin included within the fabric.

These materials are slightly conformable and can be draped. They are predominantly used on very large, continual structures such as tail elevators, flaps, and leading edges, among others. The term ‘semi‐pregs’ is commonly used for these materials as the resin is mostly on the fabric’s surface and the process of impregnation occurs in a high-temperature autoclave.

Toray Advanced Composites provides a range of materials under the Cetex® brand name employing fiberglass or carbon fabrics with a selection of resins such as PEEK, PEI, PA, and PPS resins.

The second category is reinforced thermoplastic laminates, which are related to fabric prepregs. These materials are multi‐ply-oriented laminates provided in one to twenty layers varying from as much as 12 feet in length to 4-foot-wide. An RTL laminate is subjected to a high temperature and high-pressure thermoforming procedure to attain strong fiber bundle impregnation of the higher viscosity thermoplastic resins.

An RTL laminate enables users to move directly to a short cycle thermoforming procedure to create the part. Under ceramic heaters (minutes), the laminate can be rapidly heated and then moved to a thermoforming press where a complicated part can be produced (rib stiffeners) in under five minutes.

OEM’s normally outline their specifications with multiple different fabrics, resin forms, and orientations, enabling users to refer by class, grade, orientation, and resin. Toray Advanced Composites calls these materials Cetex® RTL where RTL denotes a reinforced thermoplastic laminate.

Thermoplastic unitapes are the third type of material form, which normally range in width from a 1/8-inch slit tape (or chopped molding compound grade) to as wide as 6 to 12 inches. The advantage of this material form is the ability to use fiber placement equipment and automated tape laying for optimal efficiency.

A larger range of automation solutions are available with this form through continuous compression molding, tape laying, or fiber tape placement (in situ). Toray Advanced Composites offers these products under the brand name ‘Cetex® Thermo‐Lite’.

The State of Thermoplastic Composites Today

Thermoplastic composites have been effectively employed for many decades. There are multiple benefits of thermoplastics:

- Ability to utilize short cycle time thermoforming part fabrication techniques.

- Strong damage resistance and toughness.

- Low uptake of moisture.

- Storage at room temperature, which enables the production of a larger structure without the limits of out-time constraints.

- Parts can be re-formed.

- Fire retardancy.

- Part fabrication alternatives exist that eliminate the use of autoclaves.

- Very low void content.

Some of the limitations of thermoplastic composites in contrast with thermosets are:

- A higher initial cost for raw materials compared to thermosets.

- Processing temperatures are higher.

- Tooling is typically higher in cost.

- Traditional part makers may be unfamiliar with modern thermoplastic composite processing techniques.

One of the risks of using composites in structural applications is its resistance to crack propagation if small defects exist within the part and its ability to absorb energy without cracking upon impact.

Compared to their thermoset counterparts, thermoplastics generally have a higher toughness. This is an added benefit because composites frequently do not show surface damage even if internal damage is present.

For composites, the surface can remain unchanged when internal cracking has occurred. Due to this, having a matrix system that has the ability to resist crack growth and is not as vulnerable to damage is a major benefit.

Thermoplastics have been proven to exhibit a higher degree of toughness in typical aerospace tests, for example when testing the amount of energy required to propagate cracks in Mode I (opening mode) and Mode II (sliding mode) and compression after impact tests.

Room Temperature Storage - Prepregs can be kept at room temperature with no property degradation as there is no chemical reaction to be concerned about with thermoplastic composites.

This removes the requirement for cold transportation and cold storage that makes the logistics of using thermoset composites more complex. As out time is not a consideration, it is also possible to use more complex parts.

Re‐forming – Thermoplastic materials can be re‐formed because thermoplastic resins can be cooled and heated a number of times without impacting the properties. Parts after use can be disintegrated and used as feed materials for alternative processes like compression molding or injection molding.

Higher processing temperatures – When working with thermoplastic composites, one concern is the requirement to process the polymers at a temperature that is significantly higher than the glass transition temperature.

The glass transition temperature is commonly viewed as the service temperature for a polymer. The table below provides a summary of the glass transition temperatures and process temperatures for various thermoplastic polymers.

Table 1. Thermoplastic Polymers Used in Composites. Source: Toray Advanced Composites

| Polymer |

Tg |

Process Temperature |

Morphology |

| PEEK |

290°F (143°C) |

715° – 740°F (380° - 395° C) |

Semi-Crystalline |

| PEI |

423°F (217°C) |

575° – 625°F (300° - 330° C) |

Amorphous |

| PPS |

192°F (89°C) |

550° – 620°F (290° - 325° C) |

Semi-Crystalline |

| PEKK |

312°F (156°C) |

645° – 690°F (340° - 365° C) |

Semi-Crystalline |

| Nylon – 11 |

108°F (42°C) |

360° – 400°F (180° - 205° C) |

Semi-Crystalline |

| Nylon – 6 |

116°F (47°C) |

415° – 450°F (210° - 230° C) |

Semi-Crystalline |

Tooling – Metal tooling is typically used for thermoplastic parts because of the higher processing temperatures required and the higher pressures employed in some of the forming procedures.

While the initial expense of tooling can be higher, aluminum tools can be utilized for prototyping purposes, which helps to decrease lead times and expenses. For production applications, steel tools are normally recommended.

Other Considerations Associated with Thermoplastics

One of the novel factors related to semi‐crystalline thermoplastic polymers is the level of crystallinity and how this influences properties. Fortunately, commonly used analytical equipment like a DSC (differential scanning calorimeter) can be used to easily quantify the degree of crystallinity.

For the majority of thermoplastics, the composite is tougher when the crystallinity is lower, but this also increases its vulnerability to solvents. Highly efficient crystallization rates can be seen in many of the engineered thermoplastics. This means that the degree of crystallinity within a part will show very little variation within the cooling rates found in typical fabrication processes.

Another critical factor with any composite structure is how it can be attached to other structural elements. Similar to thermoset composites, thermoplastics can be adhesively bonded, but there is also a range of welding processes that can be employed.

The bondline must be heated up to the processing temperature to soften the material in order to weld structures. To avoid delamination, measures must be taken to ensure that pressure is maintained in any heated area. Heat can be applied through a number of different methods such as resistance, induction, friction, ultrasonic, and laser.

Manufacturing Processes

New developments in automated processes are decreasing the cost of manufacturing thermoplastic parts. These developments address the demands of the composite industry to decrease the processing costs of composite parts.

Due to the nature of thermoplastics, there are a number of these techniques available at present to produce parts efficiently and cost-effectively. Thermoplastics are rapidly formed at the processing temperature.

As no chemical reaction is included, a standard thermoplastic consolidation cycle requires the material to remain at the processing temperature until the complete part reaches the processing temperature.

A press can be used to form a number of thermoplastics into shapes with highly efficient cycle times. There are several automated processes being produced by different companies to optimize the quality and manufacturing speed of thermoplastic parts. The most widespread techniques are outlined below.

Automated Fiber Placement and Tape Placement

Organizations are using slit tape and thermoplastic composite tows for the production of parts. The tape is laid down on a tool or mandrel under temperature and pressure, which consolidates the material during placement, meaning no additional processing is required.

Automated Dynamic. Image Credit: Toray Advanced Composites

Fiberforge. Image Credit: Toray Advanced Composites

As this process is relatively low-pressure, it is crucial that the unitapes employed in the process have very low void contents.

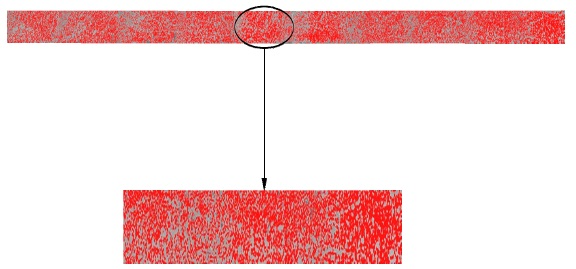

The technology adopted by Toray Advanced Composites to manufacture thermoplastic unitapes inherently supplies excellent polymer distribution and low void contents. The photomicrograph below shows the fabrication of a thermoplastic unitape laminate under very low pressure.

Figure 1. A cross-section photo showing Toray Advanced Composites’ TC1200 PEEK unitape laminates. Note the very even resin distribution around the carbon fiber tows and the low void content in the laminate. Image Credit: Toray Advanced Composites

Thermoforming

Thermoforming for thermoplastic composites is analogous to the thermoforming procedure that is commonly employed for non‐reinforced plastics.

A consolidated thermoplastic laminate is heated to the processing temperature typically utilizing IR heaters that take several seconds to a few minutes to heat the part to the required temperature. This is moved to a stamping station where a female and male mold are employed for part formation. The total duration of the part formation process is frequently less than five minutes.

Robotic Lay‐up

Machinery is available to efficiently lay down thermoplastic tape in the fiber orientation dictated in the design. A local heating source is used to tack the plies together. The subsequent blanks are then press consolidated and thermoformed into parts.

ACM/Experion. Image Credit: Toray Advanced Composites

Continuous Compression Molding (CCM)

CCM is a semi-continuous, automated manufacturing technique with the ability to take thermoplastic composites and create flat panels or highly shaped profiles of practically unlimited length.

Summary

There are several material options available in the field of structural composites. The composites industry is currently focusing on the discovery of cost-effective manufacturing methods to help to decrease the total cost of parts. A key focus is towards the fabrication of parts where processes are used that do not include an autoclave.

Composites reinforced with thermoplastic polymers give manufacturing engineers and designers a range of different processes where parts can be reliably and quickly produced.

With the added advantage of superior toughness, room temperature storage, an almost unlimited shelf life, the ability to combine structures using welding, and modern developments in automation, thermoplastic composites will continue to be applied in an increasing number of applications.

Acknowledgments

Produced from materials originally authored by Dan Leeser from Toray Advanced Composites.

This information has been sourced, reviewed and adapted from materials provided by Toray Advanced Composites.

For more information on this source, please visit Toray Advanced Composites.