In this interview, Dirk Laeveren and Mark Riccio, Product Marketing Managers for the microCT product line at Thermo Fisher Scientific, discuss microCT, including the possibilities it provides in various applications, and ways to combine microCT with other visualization techniques.

How has microCT technology evolved since your first experience of it?

Mark: In the last 15 years, microCT technology has evolved tremendously with the use of X-ray detectors, X-ray sources, and computational hardware. The biggest advances were in the reconstruction algorithms. With larger datasets, the need for computer clusters was paramount. Today, a 400 nm resolution is possible. In 2004, we were happy with 25-50 um. This enables new and previously impossible discoveries.

Dirk: Ten years ago, we were thrilled when we were able to reconstruct a dataset of 20 gigabytes. Today, that is easy with the current computer technology as datasets that are 10x bigger are very common. This is because we now use helical trajectories - generation larger datasets - instead of the conventional circular trajectories.

The HeliScan MicroCT

What about the applications microCT can be used for?

Dirk: MicroCT has multiple applications, including batteries, polymers, additive manufactured parts, electronics, and rock samples. The size and “transparency” for X-rays play an important role. The tunable X-ray source with an extremely small spot size for the highest resolution in class allows for multiscale exploration of samples of all shapes, sizes, and densities. That includes researchers from materials science, engineering, geology, life science, and everything in between. If you want/need to visualize and quantify structures inside the samples and objects you work with, but do not want to cut the sample open, microCT is game-changing technology.

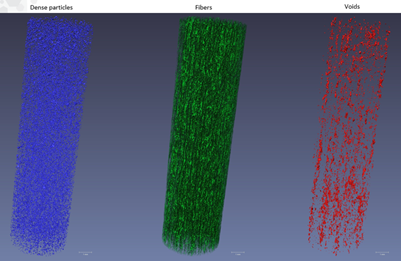

Segmentation of a fiber-reinforced cement sample

What was the most challenging sample you have ever visualized?

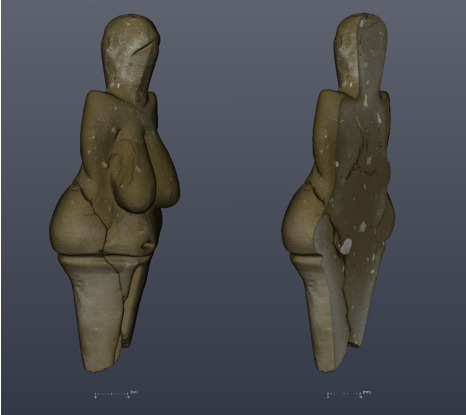

Dirk: When we visualized the internal structures of the Venus of Dolní Věstonice, an archaeological artifact of over 25,000 years old, I was stunned. The statuette came to our labs in an armored car accompanied by armed police officers – quite spectacular.

Mark: I vividly recall a “space-hardened”, fully populated printed circuit board that was holding up a rocket launch and required several long days of imaging and analysis searching for the root cause of a failure.

Surface rendering and an orthogonal slice of Venus of Dolní Věstonice kept in the Moravia Museum in the Czech Republic

Is microCT valid as a standalone technology?

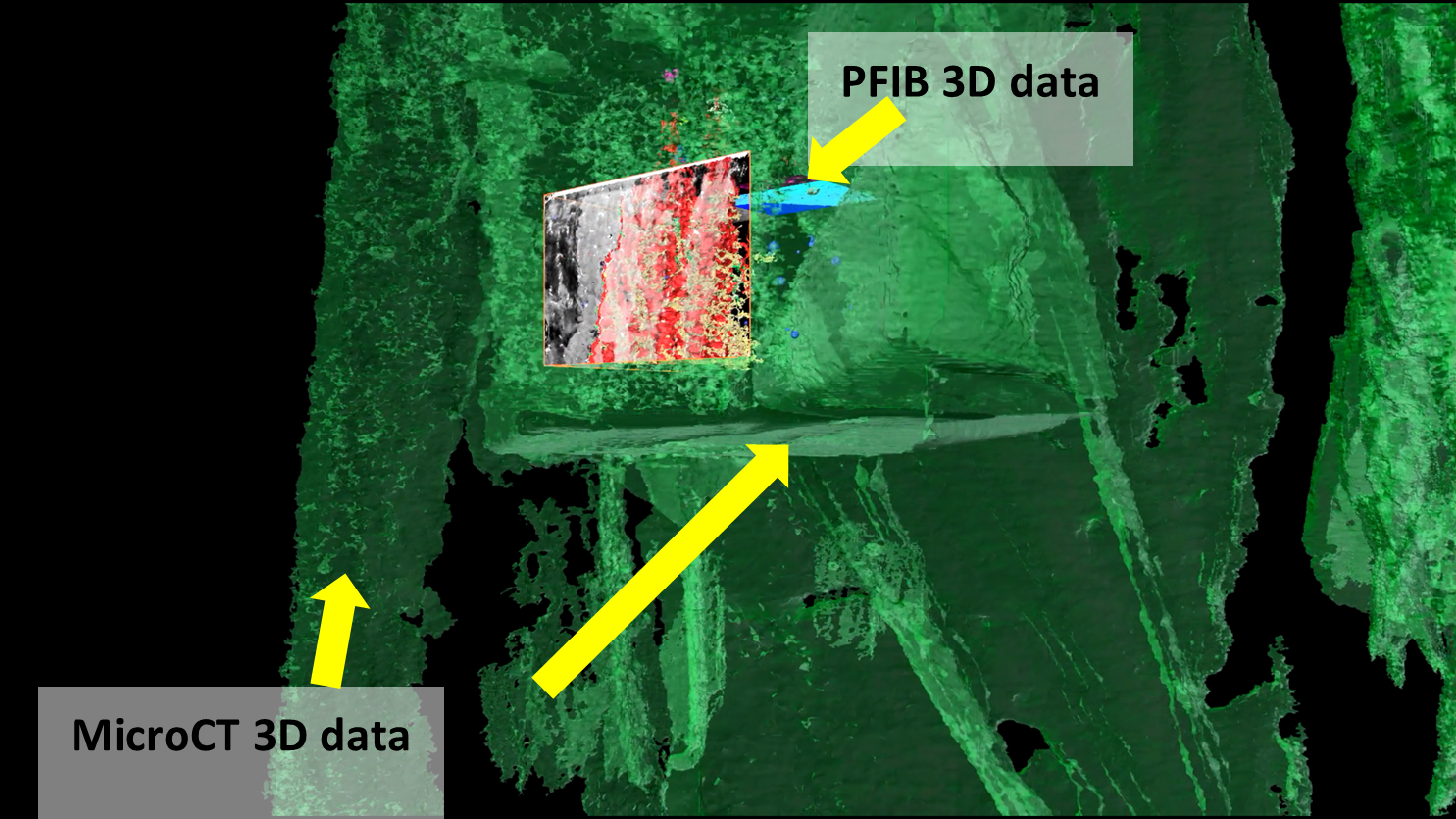

Dirk: microCT is clearly valid as a standalone technology, but there is a trend towards multiscale and multimodality. We offer multiscale in the combination of HeliScan microCT to Helios PFIB with a common holder and integrated software to Talos TEM via AutoTEM. Standalone can produce important results. However, more and more state-of-the-art research studies require knowledge of multiple-length scales and combine micro, nano, and atomic-scale datasets/results.

Combination of 3D micro CT data acquired by HeliScan and PFIB data acquired by Helios

What is the “next big thing” in microCT?

Mark: Automation. Currently, you do not have to worry about the alignment of the sample in HeliScan. The sample is automatically aligned in the best possible position to get maximum resolution. I believe the level of automation will continue to evolve. As throughput increases via advances in hardware and software technologies, additional layers of characterization will be possible and near-line, as well as in-line 3D X-ray applications, will become possible. New types of 4D and in-situ experiments in Academic and R&D labs will also be enabled. Detectors and sources will play an important role in that process. Speed, resolution, and big volumes.

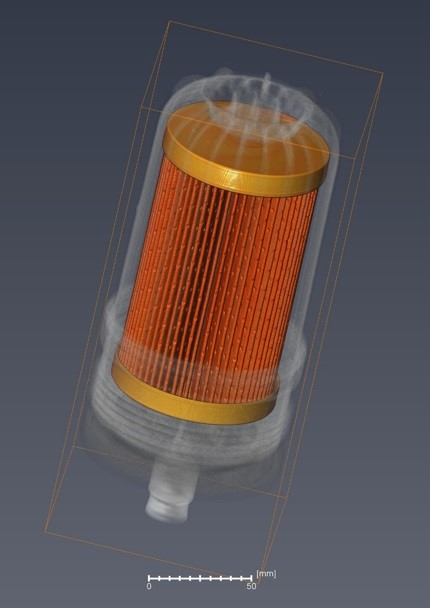

3D visualization of a large oil filter (Ø 120 mm) of a stationary diesel engine

About Dirk Laeveren

Dirk Laeveren is Product Marketing Manager micro-CT at Thermo Fisher Scientific - Materials & Structural Analysis. Dirk’s educational background includes a degree in engineering and marketing. He spent most of his career in Europe and the US working for companies active in the field imaging technology and has vast experience and knowledge of micro-CT. Over the 6 past years Dirk has been active to bring Thermo Scientific’s micro-CT HeliScan™ to the next level of quality and user experience.

About Mark Riccio

Mark Riccio is a product marketing manager at ThermoFisher Scientific focusing on X-ray based imaging systems (Heliscan Micro CT) for the materials science and engineering research markets. In this role, Mark coordinates closely with the customer base in the Americas and Canada to provide solutions for challenging imaging and analytics tasks using the latest innovations and methods. Mark received his Masters in electrical engineering from Cornell University, where his research focused on signal processing as applied to cardiac electrophysiology. He began work with non-invasive 3D X-ray imaging in 2008 and became a champion for leveraging the technology to create solutions for diverse academic and industrial applications while leading the Multiscale X-ray facility at Cornell University.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.