In this interview, Joerg Koehler, Head of Business Unit Industrial at Bruker BioSpin talks to AZoM about the benefits of Electron Paramagnetic Resonance and what is it used for.

What is Electron Paramagnetic Resonance and what is it used for?

In the past, Infrared and Raman spectroscopy were commonly used to investigate polymer structures, and mass spectrometry is certainly an indispensable tool for polymer analysis. It is widely used to study polymer composition, polymer structure, molecular weight, and impurity content.

EPR, however, works by measuring the presence of paramagnetic ions or molecules with unpaired electrons, and by observing the resonant absorption of microwaves within a static magnetic field.

We can use Electron Paramagnetic Resonance (EPR) to study radical reactions in polymers, and because EPR is a non-invasive and non-destructive magnetic resonance technique, it is perfect for detecting paramagnetic species like free radicals, bi-radicals, transition metal ions, triplet state systems, and point defects.

These paramagnetic species are found in many materials, so EPR is an indispensable tool in polymer science. While the applications of EPR in polymer science are varied, they can be loosely grouped into five key areas: thermal or chemical degradation, optimizing product shelf life, reaction monitoring, sterilization quality control, and paramagnetic impurity profiling.

Image Credit:Shutterstock/Sanit Fuangnakhon

How does the use of EPR help manage controlled radical polymerization?

Radical reactions are central to processes like polymerization, cross-linking, and degradation, and we can use EPR to help monitor and manage these reactions. Many natural or synthetic polymers are also prone to autoxidation, which is a process involving photo- or thermo-oxidative degradation of the polymers.

The radical reactions taking place in polymers are varied, and these can include queuing or cross-linking which usually occurs in the presence of organic peroxide, while the drying of resins and oils will often precede other radical mechanisms.

These materials will cross-link and solidify via a reaction with atmospheric oxygen, producing hydrogen peroxide before composing to form oxygen centered radicals. These reactions must be monitored and managed if we are going to make sure that polymers maintain their desired qualities, and that is where EPR can be useful.

Radical autoxidation in polymers typically starts with initiation before moving through the propagation, chain branching, and termination reaction stages. This process always begins with the formation of an initiating radical, and it is these free radicals that can be detected, identified, and quantified using EPR.

Can you give our readers some examples of the practical applications of EPR?

EPR can be used in a wide range of applications. To begin with, let’s talk about using EPR to help address degradation in paint polymers. Hindered amine light stabilizers (HALS) are often added to paint polymer as a radical scavenger, designed to prevent polymer degradation resulting from light exposure.

As the polymers in paint are exposed to UV light, there is a degradation leading to the formation of polymer radicals. HALS reacts with these polymer radicals and is oxidized forming HALS radicals, which are detectable by EPR.

Over the past few decades, there has been increased interest in the modification of polyolefins via controlled degradation and cross-linking, aiming to create specific end-product properties. EPR can be used to verify the free radical mechanisms involved in these types of modification processes.

EPR can also be used to help manage sterilization in ultra-high molecular weight polyethylene (UHMWPE). This is one of the most frequently used materials in joint replacement manufacture.

EPR has numerous roles in the development of vulcanized and what is known as ‘self-healing’ rubber. Rubber can be subjected to a vulcanization process to create a three-dimensional polymer network, which is responsible for many of the characteristic properties of these materials. Sulfur and organic peroxide are often used as vulcanization agents, and we can use EPR to help determine the presence and concentration of free radicals that may affect this process.

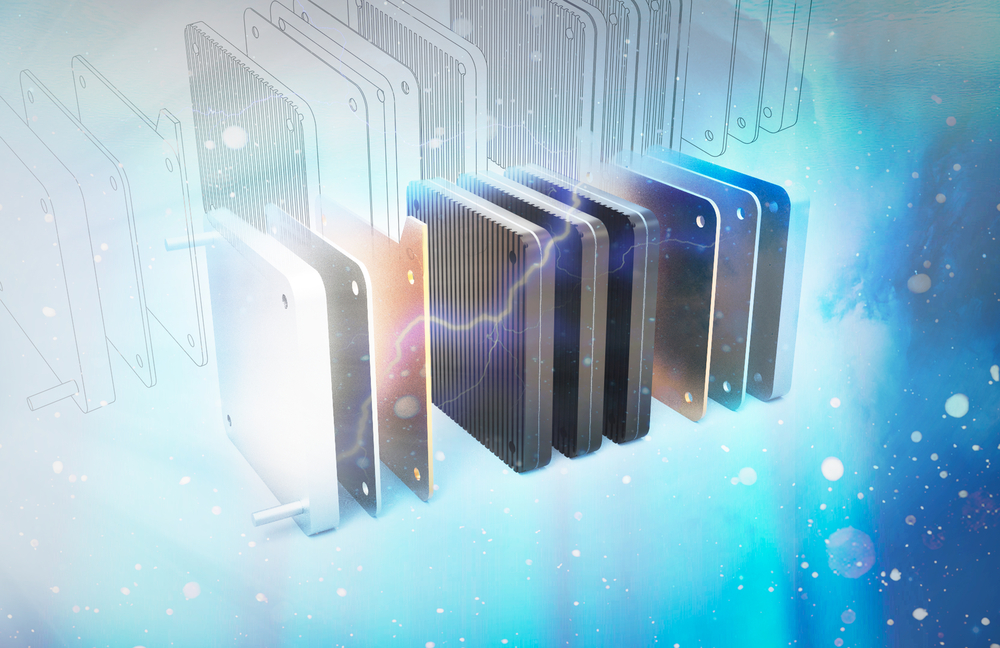

A particularly exciting application of EPR is in the study of photovoltaics and fuel cells. The pure silicon used in solar cells or polymers for organic photovoltaics has very limited availability, so it is important that it is used efficiently.

Image Credit: Shutterstock/Polina Krasnikova

We have to develop accurate specifications for concentrations of defects and impurities in order to maximize product yields and crop targets. We can use EPR to study defects in starting materials like pure silicon, testing these to calculate the number of paramagnetic defects or impurities.

Nafion membranes are found in conductive polymer films, and these are useful in that they only allow protons to pass through them. However, if these membranes are exposed to reactive oxygen species such as hydrogen peroxide or short-lived oxygen radicals, this can lead to degradation of these membranes, negatively impacting fuel cell performance.

We can use EPR to study these radicals and identify their structures, helping us to understand membrane degradation mechanisms, and ultimately leading to improvements in fuel cell efficiency.

Perhaps one of the most crucial applications of EPR is its use in environmental technologies and waste reduction. For example, when microplastics are exposed to sunlight, large amounts of environmentally persistent free radicals and reactive oxygen species form on their surface. We can use EPR to identify and quantify these persistent radicals over time, helping us to better understand their formation pathways and long-term impact.

Biodegradable polymers are another technology that could help address waste and plastic pollution. Biodegradable bio polyester families are an attractive alternative to traditional plastics and the temporal and spatial heterogeneity of these biopolymers can be investigated via EPR, using nitroxide, paramagnetic spin probes.

Image Credit:Shutterstock/ Mr_Mrs_Marcha

How can Bruker’s EPR solutions help researchers and manufacturers in the polymer industry?

Bruker has a comprehensive portfolio of analytical systems that can help support the polymer industry in developing new optimized polymers, as well as efficiently producing plastics with high quality.

Our microESR is the smallest benchtop EPR spectrometer on the market. We also offer the online ESR for reaction monitoring in polymers, while the Magnetic ESR5000 is a benchtop instrument that has been specifically designed for research with polymers.

Our portfolio of instruments also includes the EMXnano, EMXmicro, and EMXplus - a new series of instruments featuring the latest digital and microwave technologies, suitable for a wide range of teaching and analysis applications.

Finally, we can also provide the Xenon software suite. Xenon is a comprehensive suite of EPR data acquisition, processing, and analysis tools, which guides the user through each step of the EPR process fro m acquisition to analysis via its range of targeted workflows.

m acquisition to analysis via its range of targeted workflows.

About Joerg Koehler

Dr Joerg Koehler studied physics and holds a doctoral degree from the Institute of Biophysics and Physical Biochemistry of the University of Regensburg. His research focused on High-Pressure-NMR based studies of folding intermediates of biochemically active macromolecules. After several positions in sales, sales management and business administration he joined Bruker as Head of Business Unit Industrial. Today Dr Joerg Koehler is accountable for Bruker’s global activities in magnetic resonance in various industrial market segments including forensics.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.