Image Credit: Fishman64/Shutterstock.com

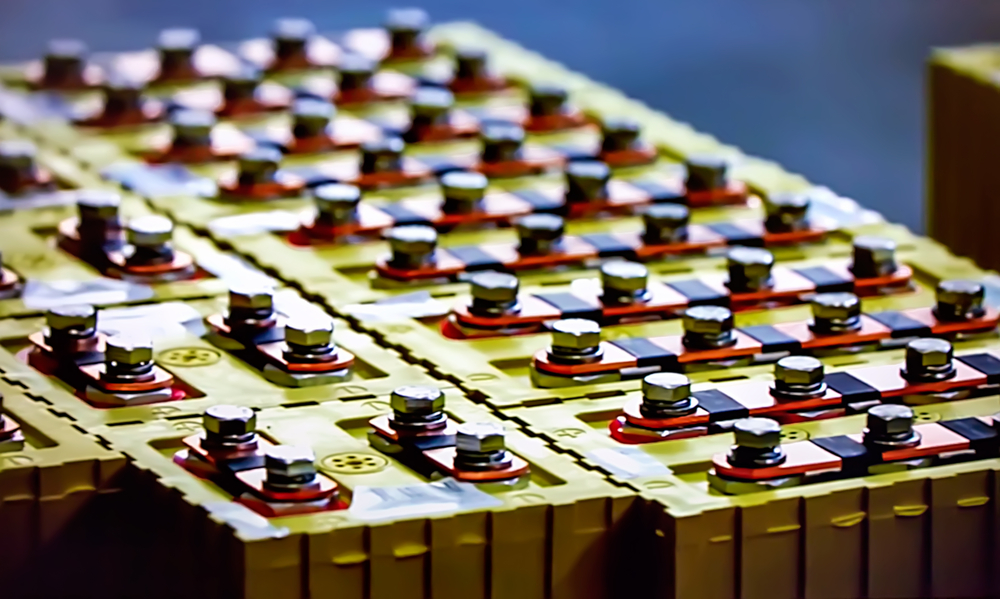

New research suggests that doping lithium metal batteries with potassium could improve performance, lifetime, and safety in the next generation of rechargeable batteries.

With increasing concerns regarding pollution and the effect of greenhouse gases on climate change, electric vehicles have never been a more attractive prospect. Producing vastly less greenhouse gas over their lifetime, including production and the generation of electric power , it is estimated that just one electric car saves an average of 1.5 million grams of CO2 over a year compared to its fossil fuel-powered alternative model.

For the electric car to become dominant in a market in which efficiency and economy are watchwords and, in turn, become a more attractive prospect to everyday consumers, vehicles need a reliable high-energy-density battery. This battery should reduce the need to fuel up on long-haul trips and be stable and long-lasting.

The Problem with Electric Vehicle Batteries

This need currently represents a problem for electric vehicles. The batteries that they rely on for power are not as reliable and efficient as they could be. In particular, the lithium metal batteries' lifetimes that currently power electric cars need to be substantially improved.

However, such a battery would not just benefit electric cars. Its uses would expand to the aviation industry and marine applications.

While these batteries do not currently exist, the next generation of lithium batteries that power future electric cars could also be adapted to fulfill this role. The lithium metal battery is strongly considered one of the most promising candidates for high-energy-density energy storage devices in our modern and technology-based society.

Successful commercialization can only happen if the challenges that face the development of such batteries can be overcome. One of the main challenges that currently limit this technology is what happens to anodes in lithium metal batteries during operation.

Spiky, irregular structures called dendrites grow on these rechargeable lithium metal batteries’ anodes during operation. When these spikes grow long enough to reach the other electrode, it can cause short-circuiting, fires, and even in rare cases, explosion. Therefore, this major safety concern has to be addressed and eliminated before lithium metal batteries can be more widely adopted.

Many solutions to mitigate dendrite growth have so far been suggested, including physical separators, anode modifications, and anode surface coatings. However, researchers at Columbia Engineering believe they have found the ideal fix.

In research published in the journal Cell Reports Physical Science, the team suggests using alkali metal additives — such as potassium ions — to prevent lithium microstructures from proliferating during battery use.

How Dendrites Form and How to Stop Them

Uncontrolled growth of lithium dendrites in lithium metal batteries occurs during the charging and discharging cycle of operation. The cause of the problem is not currently fully understood, but scientists believe it happens when lithium ions travel to the anode and start to collate and form dendrites. The Columbia Engineering team found that potassium ions mitigate the formation of undesirable chemical compounds that deposit on lithium metal surfaces.

The team added small amounts of potassium salts to a conventional lithium battery electrolyte, discovering that this caused some unique chemistry to occur when the lithium and electrolyte meet. This has the effect of preventing lithium-ion transport during battery charging and discharging, limiting microstructural growth.

This technique that uses alkali metals additives to suppress dendrite formation differs from other currently favored dendrite mitigation strategies as it does not require manipulating electrolytes or coating anodes with polymers—things which can reduce performance.

To reach their findings, the team used a sophisticated blend of microscopy, nuclear magnetic resonance (NMR), and computational modeling. The work marks the first time that NMR has been used to characterize the chemistry at the surface of lithium.

The team believes that using NMR and computer simulations could finally lead researchers to discover how different formulations of electrolytes can improve lithium metal batteries' performance and safety. It could also provide scientists with an answer as to why dendrite spikes form and how this formation can most effectively be halted.

This means that even if the team’s technique is not widely adopted, they have set out a roadmap for future in-depth analysis of lithium and its interaction with an electrolyte. This could point to the development of an optimal lithium metal battery design.

With the electric car industry currently projected to reach a value of $133.46 billion US by 2027, the quest to find high-performance, safe, and economical battery tech is heating up.

References and Further Reading

May. R., Zhang. Y., Denny. S. R., Viswanathan. V., Marbella. L. E., [2020], ‘Leveraging Cation Identity to Engineer Solid Electrolyte Interphases for Rechargeable Lithium Metal Anodes,’ Cell Reports Physical Science.

Cheng. X-B., Zhang. R., Zhao. C-Z., Zhang. Q., [2017], ‘Toward Safe Lithium Metal Anode in Rechargeable Batteries: A Review,’ Chemical Reviews.

Jansen. K., [2019], ‘Battery scientists tackle the dendrite problem,’ C&EN.

‘Electric Vehicle Battery Market by Type (Lead-Acid Battery, Lithium-ion Battery), by Vehicle (Battery Electric Vehicle, Plug-In Hybrid Electric Vehicle, Hybrid Electric Vehicle), By Geographic Analysis And Forecast,’ [2020], Verified Market Research.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.