Metrohm can help organizations and individuals to perform the best possible analysis using Near-Infrared Spectroscopy (NIRS), whether they are new to the technique, simply curious about NIRS and its applications, or an experienced practitioner.

Image Credit: Metrohm AG

What are Typical Detection Limits for Liquid Samples and for Solid Samples?

Detection limits will vary depending on the substance under analysis, sample matrix complexity, and the sensitivity of both the NIR technology used and the reference.

The most sensitive NIR spectroscopy systems employ dispersive technology, and these systems can offer low detection limits when analyzing a simple sample in which the parameter of interest is a strong absorber.

For example, it is possible to detect water in solvents down to around 10 mg/L, and this is achievable in both offline and online/inline measurements. Detection limits for more complex matrices like slurries and solids and slurries are around 1000 mg/L (0.1%).

What Accuracy can be Achieved with NIR Spectroscopy?

A near-infrared spectroscopic method’s accuracy will be determined by the reference/primary method’s accuracy. Therefore, an accurate primary method will result in a highly accurate NIR method being developed, while in contrast, a less accurate primary method will reduce the accuracy of a related NIR method.

This dependency exists because both NIR data and primary data are correlated in the prediction model; a robust prediction model will offer users around 1.1x the accuracy of the primary method, over the prediction range.

How are Instruments Calibrated and How Often Should Instruments be Recalibrated?

Certified NIST standards must be used for instrument calibration, and dispersive systems measuring in reflection mode will use NIST SRM 1920 standards to calibrate the wavelength/wavenumber axis. The absorbance axis can be calibrated using certified reflection standards with a defined reflectance made of ceramic.

For systems working in transmission mode, NIST SRM 2065 or 2035 will generally be used for wavelength/wavenumber calibration, while air is used to calibrate the absorbance axis.

Calibration should be completed following each hardware modification (for example, a lamp exchange) and every year as part of a routine service procedure. The spectroscopy software should guide the user through the full range of calibration processes.

Metrohm NIRS reflection standard, set of 2. Image Credit: Metrohm AG

How are Instruments Validated and How Frequently Should Validation be Done?

NIR spectroscopy software packages will a variety of tests for instrument performance validation. The basic performance test is most common, whereby crucial hardware parts are tested alongside the system’s wavelength/wavenumber calibration and signal to noise (S/N) ratio.

In a regulated environment, further tests will be completed according to USP <856> guidelines. These will generally include photometric linearity and noise at low and high light fluxes.

Instrument performance tests must be completed regularly, with risk assessments usually dictating testing frequency.

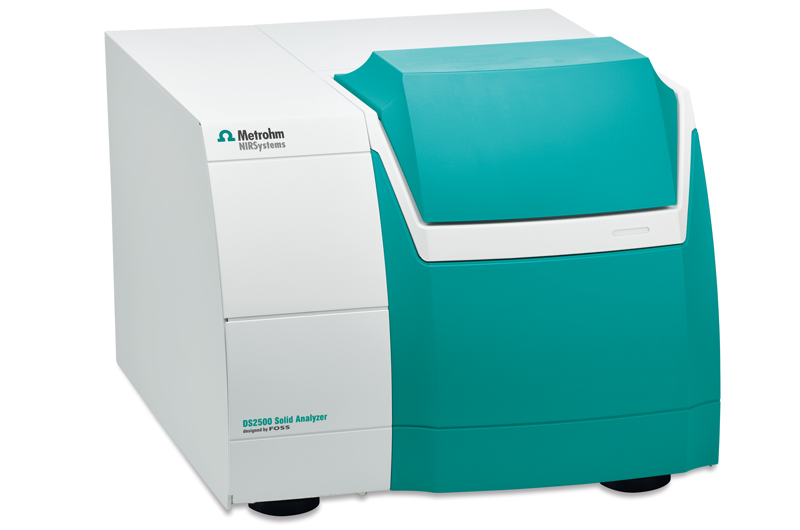

The Metrohm NIRS DS2500 Solid Analyzer. Image Credit: Metrohm AG

What Sample Types or Parameters are Unsuitable for Analysis with NIR Spectroscopy?

NIR spectroscopy cannot analyze samples containing large amounts of carbon black, because carbon black will absorb almost all NIR light. Furthermore, the majority of inorganic substances are unsuitable for NIR analysis as these do not possess absorbance bands in the NIR spectral region.

Carbon black is not a suitable sample to be measured by NIR technology. Image Credit: Metrohm AG

Is it Possible to Perform Inline NIR Analysis in Hazardous Areas, or with Industrial Processes Using Harsh Chemicals?

It is possible to perform inline NIR analysis in hazardous areas. While Metrohm manufactures a range of instruments for laboratory analysis, the company also works with industrial processes. Two versions of process NIRS systems are available: the NIRS Analyzer Pro and the NIRS XDS Process Analyzer, the latter of which is an ideal solution for hazardous environments.

Metrohm Process Analytics offers two lines of near-infrared spectroscopic process analyzers: the NIRS Analyzer PRO and the NIRS XDS Process Analyzer. Image Credit: Metrohm AG

NIRS is a versatile and robust method that facilitates simultaneous, real-time monitoring of a range of process parameters via a single measurement. Using fiber-optics in conjunction with NIRS allows a process analyzer and measuring point to be hundreds of meters if required.

Remote monitoring at large distances can be achieved with no significant impact on S/N ratios - a distinct advantage in environments that may be subject to challenging explosion protection requirements.

The spectrometer and analysis PC can remain safe and secure in a shelter, while fiber-optic probes and flow cells can be placed in a range of potentially harmful working environments.

The NIRS XDS Process Analyzer is ideal for settings where a shelter cannot be provided, as this unit can be placed directly in the hazardous area (ATEX Zone 2 or Class1Div2). This allows real-time results to be obtained with no need to take samples or handle potentially dangerous chemicals.

How is the Maintenance of a NIRS Process Analyzer Performed?

Maintenance is easy and fast and does not need to be performed frequently. Because NIRS is an analytical technique that does not use reagents, the lamp is the only consumable to be replaced, needing replacement just once a year.

Unlike other techniques like chromatography (GC or IC) or titration, and also because NIR spectroscopic analysis does not degrade samples, no chemical waste is produced.

Additionally, Metrohm’s all-in-one software allows automatic performance tests to be conducted regularly, guaranteeing that the analyzer continues to operate according to process specifications. The software also allows the instrument to be left in the process with no further operator involvement required.

Overall, Metrohm Process Analytics NIRS process analyzers are maintenance-free systems, designed to ensure low operational costs and high uptimes.

Acknowledgments

Produced from materials originally authored by Dr. Nicolas Rühl and Dr. Alexandre Olive from Metrohm.

This information has been sourced, reviewed and adapted from materials provided by Metrohm AG.

For more information on this source, please visit Metrohm AG.