Optical adhesives are employed in several industries where solvents are impractical. For example, chip and semiconductor manufacturers must avoid solvents as they can accumulate on components. Photo-DSC provides an efficient analysis of the curing profile and quantifies the energy of the curing reactions.

Accurate temperature control and responsiveness are required to achieve precise data as photo-initiated reactions are dynamic and fast. For these applications, power compensated instruments are the ideal choice.

Experimental

A PerkinElmer DSC 8000 with a UV irradiation system was utilized. An open pan is commonly acceptable, but a specialized DSC pan with a quartz cover can be used. The sample is cooled or heated to the isothermal temperature and is given time to equilibrate.

For irradiation of the sample, the Pyris™ software activates the shutter of the light source to open and close. Data can be acquired at a range of times and intensities to design the optimal cure cycle for the material.

Advantages of Power Compensation Design

For these studies, the DSC 8000 (Figure 1) is the optimum choice as the power compensated construction helps the instrument to efficiently identify and react to the optical material’s changes. The first transient is very brief, usually around 12 seconds, which provides an accurate measurement of the fast reactions with no notable energy loss throughout the transient.

Figure 1. DSC 8000. The DSC’s high sensitivity and excellent temperature control makes it ideally suited for demanding applications like photo curing studies. Image Credit: PerkinElmer

The power compensated design also supports complete isothermal operation. The power is modified to stabilize the desired isothermal temperature and it is this power compensation that is reported on the screen. This way, fast temperature increases, which are frequently related to fast reactions are accounted for.

In fact, the fast data collection rate of up to 100 data points a second, the very broad dynamic energy range of power compensation systems, and the extremely fast energy response are crucial to measure and control rapid energetic reactions.

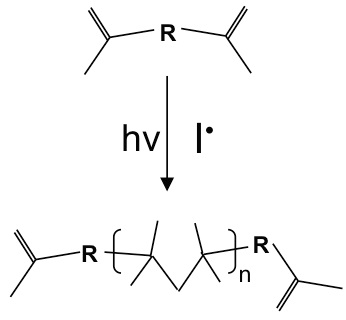

The reaction detailed in Figure 2 is the source of all the recorded energy. The highly stable design also ensures that curve subtraction processes, often employed as part of the measurement method, are fully quantitative.

Single furnace design (heat flux) systems are incapable of true isothermal operation as they cannot manage rapid energetic reactions, only perform measurements when the temperature deviates from isothermal, and have much longer transient times.

Figure 2. UV curing materials are commonly used as adhesives. UV light generates a free radical which causes the cure. Image Credit: PerkinElmer

Results

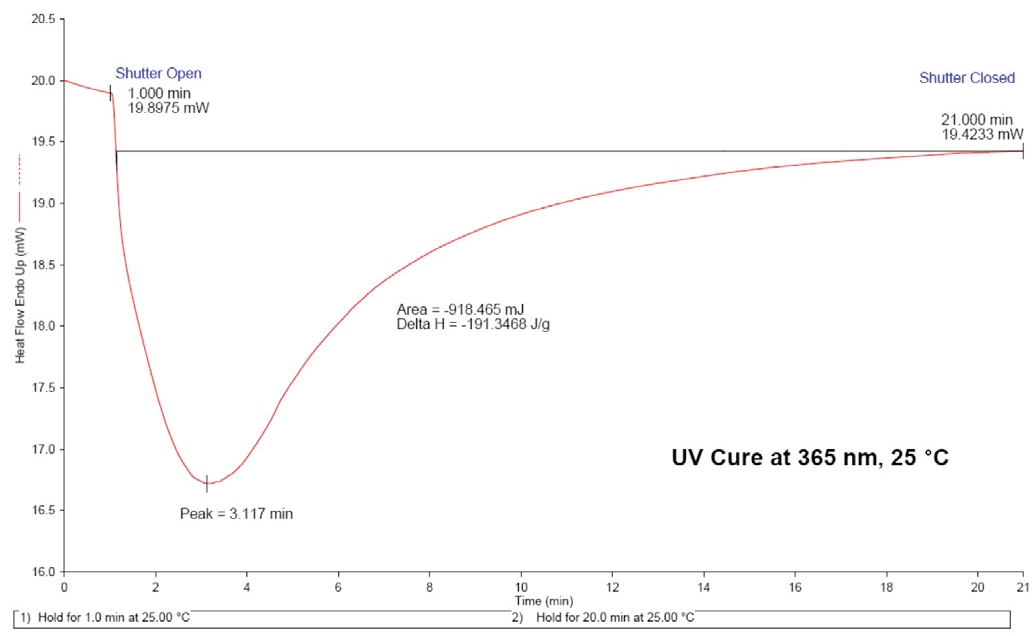

The sample is subjected to the UV light when the UV source is activated. As the material experiences polymerization, a curing exotherm is produced. The kinetics of the curing procedure can be calculated using the energy in this peak. An example of this is provided in Figure 3.

An exothermic reaction is triggered as the material crosslinks and forms a solid when the light is applied at 3 minutes for 30 seconds. Contamination of the circuit board is reduced and no volatiles are lost as the material is its own solvent.

The requirement for an efficient response is highlighted by viewing the thermogram where the maximum of the exotherm happens very quickly after the light is applied. The area beneath the peak is used to measure the energy of the reaction, which is why it is crucial to be able to account for the heat originating from the UV lamp.

The exposure can be modified in relation to time along with the amount of exposures, depending on the material. Light intensity and frequency can be altered by utilizing the filters on the UV source. The temperature control of the DSC must be able to account for the energy from the lamp as UV sources produce heat.

Figure 3. DSC results from the UV driven cure of an adhesive. Light turned on at 3 minutes (red line marked shutter open) for 30 seconds. Image Credit: PerkinElmer

Conclusion

Photo-DSC utilizing power compensation methods is an effective tool for quantitatively characterizing and investigating optically curing materials. Visit http://www.perkinelmer.com for further information.

Acknowledgments

Produced from materials originally authored by Tiffany Kang from PerkinElmer, Inc.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.