A pathway for ALD-enhanced materials to be quickly developed and transitioned from lab-scale to commercial production is available for almost any application, for the first time ever. Atomic-level surface engineering on porous materials and powders has not been viable at high throughputs, until now.

Image Credit: Shuttertstock/ Yuriy Vahlenko

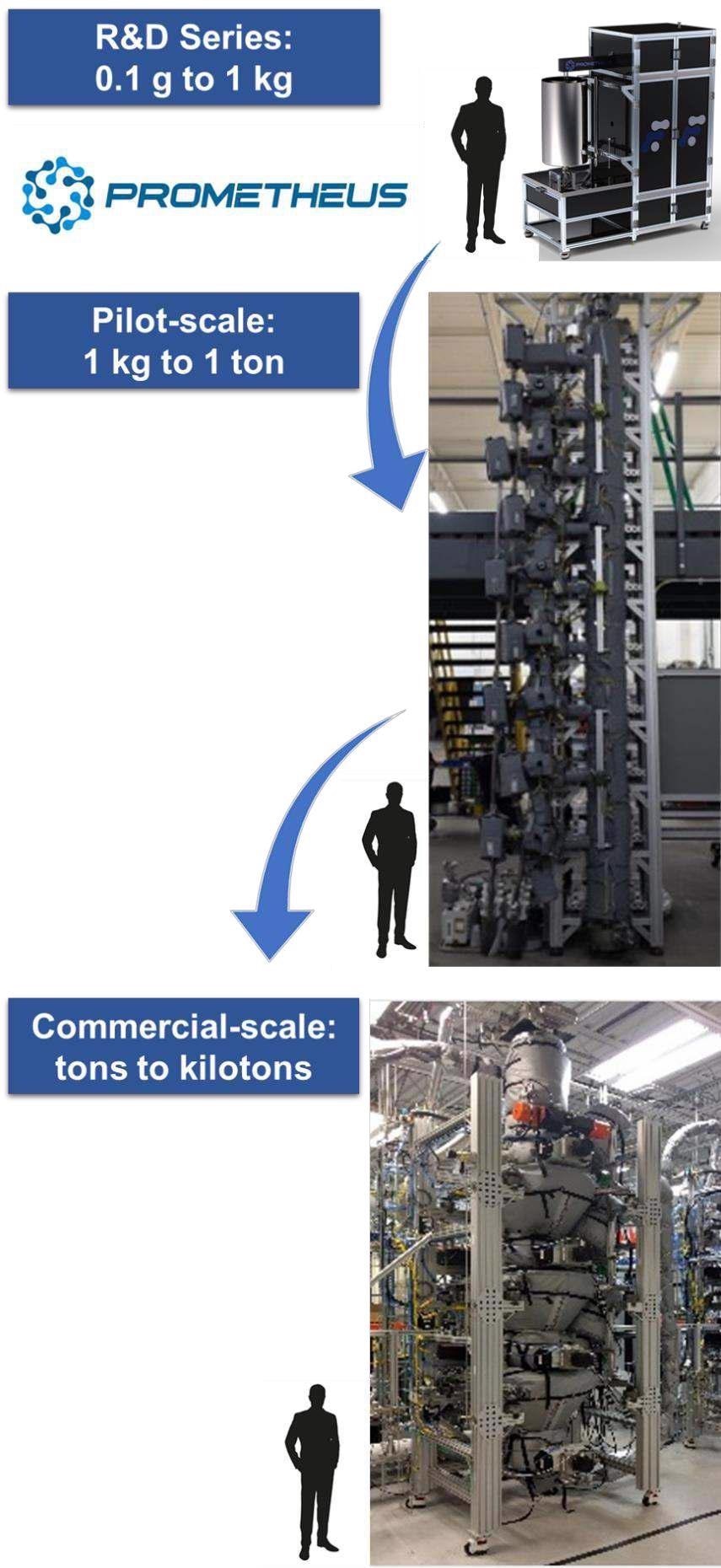

A well-defined development pathway from R&D-scale (milligram to kilogram samples) to commercial-scale production (thousands of tons per year and beyond) is now facilitating the power of sub-nano surface coatings and bulk material property control.

Over the past sixty years, atomic layer deposition (ALD) has been employed to show surface property enhancement over hundreds of applications. Commercial ALD processes which rely on costly ultra-high purity precursors are available for wafer technologies in the semiconductor industry.

Innovative applications on three-dimensional and porous materials (i.e. higher surface area materials) had sadly lagged in commercial development because of the perceived costs of ALD coatings needing these expensive precursors.

Innovations around manufacturing and scaling particle ALD products were delayed due to this. Historically, the application of ALD on porous structures and particles has been relegated to lab-scale demonstrations, usually in academic environments.

Forge Nano saw the criticality of permitting ALD for commercial applications and through rigorous design and engineering efforts they developed and patented apparatus and a technique for high-throughput (spatial) ALD for high surface area substrates.

A pathway for ALD-enhanced materials to be quickly transitioned from lab-scale demonstration to commercial presentation is now available for new product development for the first time ever.

Researchers worldwide have proven real benefits of ALD coatings on particles for markets including healthcare, catalysts, batteries, pigments, barrier coatings, cosmetics and filtration.

Atomic layer deposition allows the alteration of surface properties without modifying bulk characteristics. This facilitates ‘drop-in ready’ solutions to circumvent commercial material challenges.

High fidelity surface engineering changes utilizing ALD can optimize properties and/or decrease the volume of changing material needed to acquire functional properties.

Talented researchers are finding new opportunities to develop and demonstrate commercially-viable materials at the lab scale; by leveraging Forge Nano’s scaling experience and world leading ALD coating capabilities, these technologies can quickly be converted to commercial products.

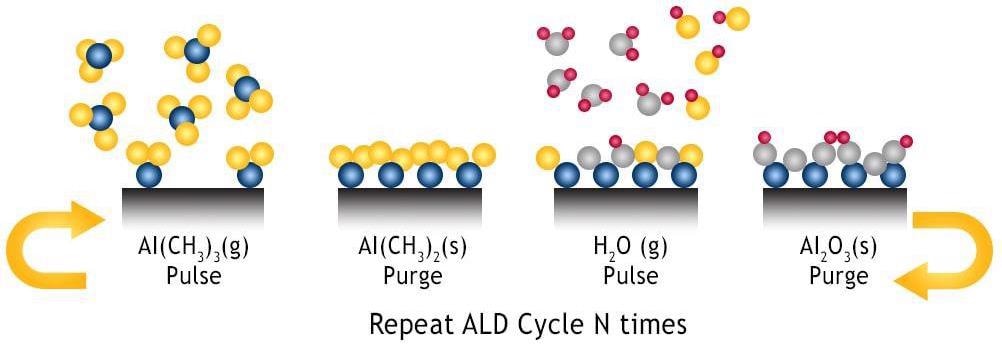

Image Credit: Forge Nano

Atomic layer deposition is carried out by sequentially dosing reactants and inert purge to build up material in a layer-by-layer process, one atom layer per cycle.

Why Should You Care About Particle ALD or Surface Engineering?

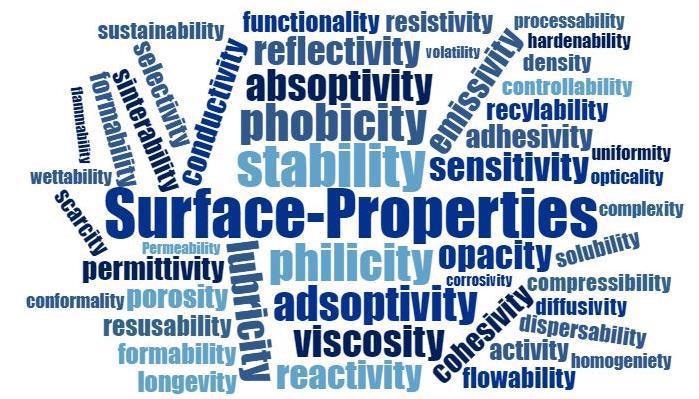

By altering the surface properties of the base particle, mechanical and physical properties of any powder can be tuned for the optimal economic performance of an end-product.

Without adjusting the bulk properties, changing surface properties affects the performance of stability, mixing, corrosion, settling, degradation and a number of other industrially relevant material handling steps in production.

Image Credit: Forge Nano

Modifying these properties can lead to significant time and process cost savings without bulk property alteration to the finished product. By adding sub-nano surfaces using ALD, industrial powders can also be protected from environmental damage without changing the bulk properties.

Why Spend Time and Intelligence Building Your Own R&D System for Particle ALD?

Forge Nano provides multiple R&D systems for particle ALD and a world-class support team with the expertise to help you innovate new materials and scale technology to commercial production levels, so your own system is not required.

The Prometheus R&D tools are available in an array of process configuration options and reactor volumes, which are adjustable to meet a user's requirements quickly. These are adaptable enough to support the ongoing requirements and ideas of a user as they evolve.

The systems are designed with swappable componentry to expand future capabilities, so they are reliable for years of operation. Prometheus tools leverage the decades of experience that Forge Nano has in building and operating particle ALD systems, so cutting edge research can begin straight away.

For a cost-effective model for academic researchers looking to upgrade their current equipment or enter the particle ALD field, the academic lite is a great choice.

The full capability, robust option enables complete versatility for feasibility testing up to small production capacity. In order to upgrade qualifying academic entry models to expand capabilities over time, transition packages are also available.

Why Should a Particle ALD Tool be Used for Particles Instead of a Modified Wafer ALD Tool?

From a practical perspective, the majority of wafer ALD tools are installed in clean room environments, which are incompatible with processing particles. Beyond this, as a properly functioning wafer ALD tool is designed to minimize particle creation and/or retention, the process software and equipment may not be backward compatible to facilitate the processing of powders.

For instance, there are usually orders of magnitude higher surface area to be coated in a given unit volume of powder than on a wafer and precursor storage and delivery is just one of many places that incompatibilities have been recognized.

A number of process variables can affect the true commercial scalability of ALD technology. Some of these are:

- Surface blocking

- Deposition uniformity

- Full precursor utilization.

- Thermal stability

- Consistency of precursor delivery

- Temperature uniformity

A particle specific reactor incorporates the particle agitation and precursor flow required to ensure reliable gas-solid mixing and uniform deposition temperatures. Forge Nano’s scale-up pathway uses the feasibility knowledge learned in a temporal ALD system (batch system) to enhance their commercial production scale spatial ALD systems.

Particle Specific ALD

R&D systems enhance the value of your R&D-scale development work and lower the scale-up risk to circumvent misleading results due to nonuniform deposition.

Research and Development in Atomic Layer Deposition for Particles and Powders

Careful attention is needed, even with trivial tasks when developing ALD processes. This is why Forge Nano is offering its Prometheus R&D tools to eliminate the biggest challenge heard by customers, inconsistent results that come from poorly-adapted wafer ALD tools.

This product line is a reliable R&D tool, where conditions can be mapped to Forge Nano’s larger manufacturing tools with scalability that is proven. Reactor control and process conditions are vital to create repeatable and reliable end materials.

Analytical integration is a key tool to elucidate if the desired reactions are proceeding. Forge Nano has navigated the development pathway from R&D to commercial production for various products with great success.

With their Prometheus R&D Series tools, they now enable others to do the same. In their systems, safety and control are key, permitting researchers at any skill level to focus their analytical and innovation skills to develop new products instead of troubleshooting reactor problems.

Capabilities of an R&D Series Particle ALD Tool

Systems range in price point from the academic-lite version to the full capability systems, including ozone precursor capability, up to eight precursor source delivery options, gas-solid mixing aid, air-free glovebox handling reactor and integrated mass spectrometer or any combination of these features.

For specialty materials and deposition chemistries, air-free operations are extremely helpful. For in-house production scale-up or object coating capabilities, reactor production sizes range from milligram to kilogram batch size.

Scale up Process

Using experts in the field of material handling at scale, precursor delivery and stability, in addition to safety of reactants and by-products, are vital to successful commercialization.

Affiliate development with an engineering and production team that can scale your process design to meet market-based production goals to facilitate R&D technology success. New opportunities can be created for a manufacturable, viable and cost-effective market solution.

Image Credit: Forge Nano

Speed of Development for First to Publish, First to Patent and First to Market

Using the best partnerships and tools quickens the pace of R&D for the fast assessment of new chemistries and associated applications. Operational inefficiencies and system downtime are costly; Prometheus Series tools have been designed for performance with long operating life and optimized for R&D success.

Specially designed valves minimize downtime during maintenance while precursor quarantine maintains cleanliness of process lines. Prescribed safe operating boundaries decrease risk while automated control operation and emergency stop logic improve safety.

Customized recipe building allows quicker innovation with inherent safety enabling autonomous operation with no human intervention. Instead of building and troubleshooting a do-it-yourself lab-system, these advantages enable researchers to focus their valuable time on new material development and product characterization.

This information has been sourced, reviewed and adapted from materials provided by Forge Nano.

For more information on this source, please visit Forge Nano.