In this interview, AZoM talks to Yuri G.M. Rikers and Herman Lemmens, Talos Product Marketing Manager and Industry Market Development Manager for Thermo Fisher Scientific respectively, on the topic of the new Automated Particle Workflow (APW) product and the new horizons it opens for those conducting nanoparticle analysis.

Tell us about your new product, ‘Automated Particle Workflow’ (APW)?

Yuri: Automated Particle Workflow (APW) offers a better and faster way to characterize nanoparticles. Nanoparticles are being used more and more in applications ranging from food additives to cosmetics, alloys for turbine blades, and catalysts present in car exhaust systems.

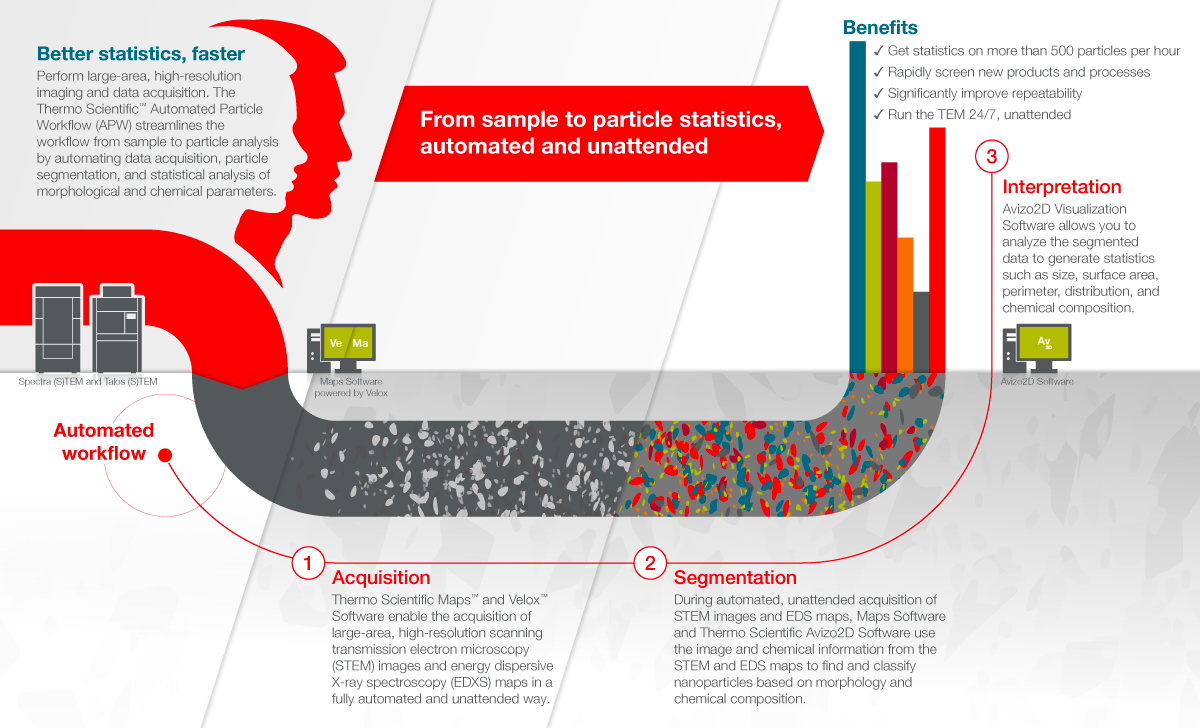

APW is an Automated Particle Workflow that makes the characterization of this wide range of nanoparticles in a transmission electron microscope much easier and faster.

Transmission electron microscopes are generally used when the particles under investigation are at the nanoscale.

With APW, we have automated the data acquisition process for these particles, making it possible to acquire data over larger areas and enabling a statistically relevant number of particles to be measured, in a much shorter time.

APW provides a large area, high-resolution imaging and chemical analysis at the nanoscale, with on-the-fly data processing.

See the full version here.

Can you tell us a bit about why APW was developed – why now?

Herman: There is an increasing amount of interest from application areas such as catalysis, batteries, and metals, where organizations and labs need to obtain meaningful statistics to make better-performing products and get these to market faster.

Automating the characterization of nanoparticles is a major factor in speeding up this process.

What are some of the biggest benefits of APW?

Herman: Using APW, we are not only able to investigate over 500 particles per hour (instead of a previous total of 50), but we can do this fully automatically and unattended.

This means while it is possible to increase the throughput and generation of statistics during the day, you can even use it during the night or weekend when the microscope would normally sit idle.

Yuri: APW removes the operator-induced bias that stems from manual measuring. Measurements via APW are faster and better because the statistics are based on more samples, and they are not skewed by operator bias.

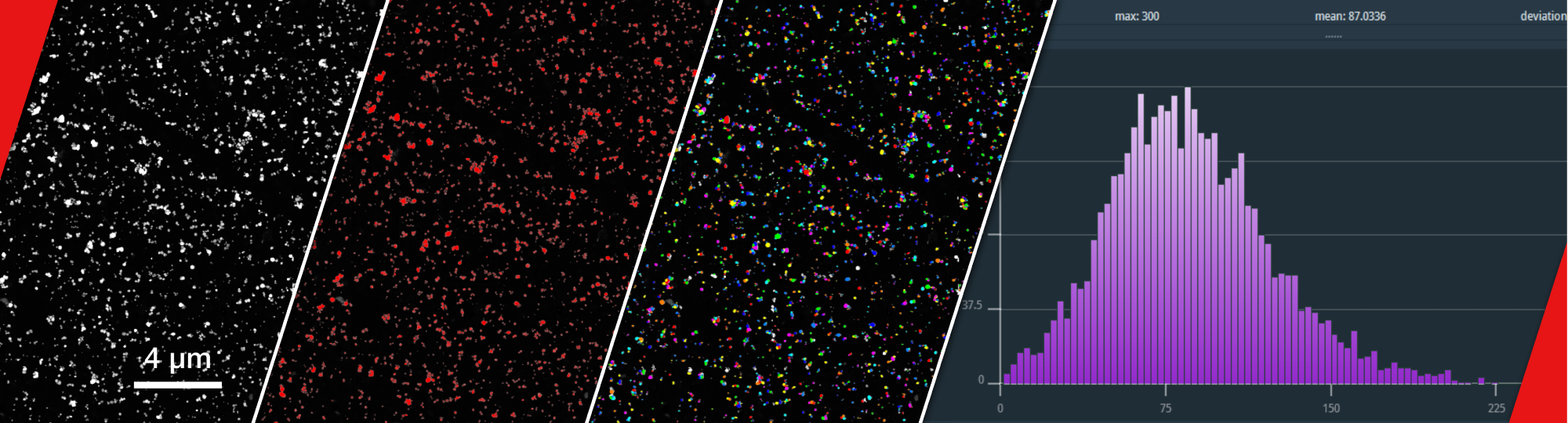

APW characterization of food additives. See more application examples here.

How can APW be applied to your TEM instruments, and what is the importance behind this?

Yuri: APW is available on Thermo Scientific Talos (S)TEM and Thermo Scientific Spectra (S)TEM systems, allowing users to obtain meaningful statistics on nanoparticles and precipitates in an automated and unattended way.

Our customers will be using this to automate a wide range of measurement processes, allowing them to simplify their workflows while increasing throughput and ultimately lowering costs.

How is APW truly revolutionizing the field?

Yuri: APW offers a truly one-stop-shop for the whole automated workflow, including (S)TEM and Energy Dispersive X-ray Spectroscopy (EDS). The APW package includes everything necessary to automatically analyze a wide range of samples, as well as upgrade possibilities for existing Talos or Spectra (S)TEM systems.

The package includes a comprehensive suite of acquisition software, including Thermo Scientific Maps 3 Software for (S)TEM and EDS enabled by Thermo Scientific’s Velox software and Thermo Scientific’s Avizo2D software, which facilitates processing on a dedicated data processing computer, as well as offering a powerful bridge between acquisition and other processing software packages.

APW offers exceptionally fast, industry-leading acquisition times with relevant information on chemical composition, morphology, and structure (for example, nanoparticle shape, size, and distribution) available in a short time.

In fact, it is possible to obtain a 25 x 25 μm image with nanometer resolution in under 20 minutes using APW.

Finally, what are some of the different applications of APW?

Herman: Nanoscale research is important because materials generally exhibit drastically different properties at the nanoscale compared to the macroscale. (S)TEM instrumentation and EDS are often employed in the study of nanoparticles, but these processes are necessarily complex and time-consuming. APW can help automate these processes, allowing more statistically relevant data to be acquired faster.

Similarly, catalysts are essential in almost every contemporary industrial process. The effectiveness and efficiency of catalytic particles are dependent on their morphology and microscopic composition, two factors that can be studied using EM with EDS.

Nanoparticles are also found in consumer goods like cosmetics, food additives, and paints, or as precipitates/inclusions in metals such as aluminum, steel, and the so-called superalloys in the aerospace industry.

Learn more about the Automated Nanoparticle Workflow (APW) at the website

Learn more about the Automated Nanoparticle Workflow (APW) at the website

About Herman Lemmens

Herman Lemmens is Market Development Manager Industry for Thermo Fisher Scientific, based in Eindhoven, The Netherlands. His main focus is developing imaging and analysis workflows for the Metals and Energy industries. These workflows typically involve imaging at different length scales, both in 2D and 3D and linking the results together with dedicated software. Herman holds a Ph.D. in Solid State Physics from the University of Antwerp. He served as Distinguished Lecturer for the SPE and Distinguished Speaker for the SPWLA on the topic of Multi-scale Imaging and Analysis.

Herman Lemmens is Market Development Manager Industry for Thermo Fisher Scientific, based in Eindhoven, The Netherlands. His main focus is developing imaging and analysis workflows for the Metals and Energy industries. These workflows typically involve imaging at different length scales, both in 2D and 3D and linking the results together with dedicated software. Herman holds a Ph.D. in Solid State Physics from the University of Antwerp. He served as Distinguished Lecturer for the SPE and Distinguished Speaker for the SPWLA on the topic of Multi-scale Imaging and Analysis.

About Yuri G.M. Rikers

Yuri G.M. Rikers studied Applied Physics at the Eindhoven University of Technology. He started working at Thermo Fisher Scientific in 2002 and had several roles ranging from TEM Service Specialist to Senior Applications Specialist TEM, supporting the Tecnai, Themis, and Talos TEM product series worldwide. Since 2015, Yuri has been working as a Talos Product Marketing Manager for the Materials Science Business Unit, with a special focus on TEM Automation & Automated Nanoparticle Workflows.

Yuri G.M. Rikers studied Applied Physics at the Eindhoven University of Technology. He started working at Thermo Fisher Scientific in 2002 and had several roles ranging from TEM Service Specialist to Senior Applications Specialist TEM, supporting the Tecnai, Themis, and Talos TEM product series worldwide. Since 2015, Yuri has been working as a Talos Product Marketing Manager for the Materials Science Business Unit, with a special focus on TEM Automation & Automated Nanoparticle Workflows.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.