Image Credit: Stable Micro Systems Ltd

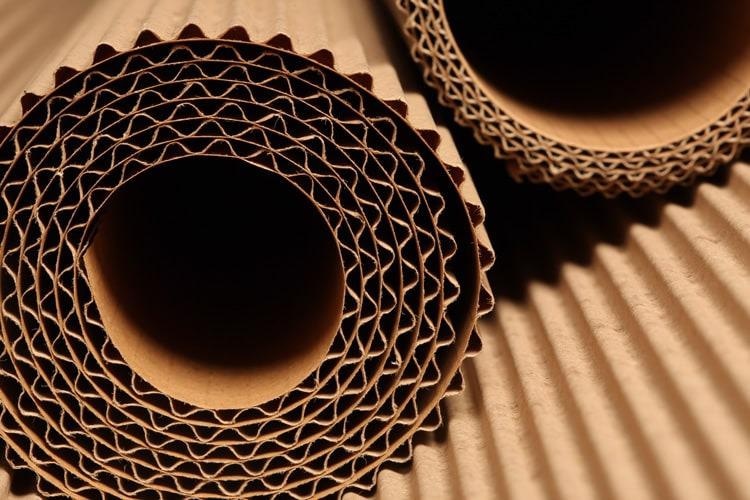

Corrugated cardboard is used all over the world for strong, cheap, and light recyclable packaging. Many boxes are made to certain customers’ demands, and the aim of these tests is to maximize strength (meeting the customer’s needs) while minimizing costs from component materials and weight.

Strength properties can be quantified using either imitative or more traditional, fundamental methods. Unlike traditional crush testing equipment, which only records the maximum force during a test, Stable Micro Systems Texture Analysers, along with Exponent software, allow full graph analysis.

They are also multi-functional – consequently, many paper, cardboard, and box tests may be performed on one instrument, including crush, puncture, flexure, and tensile tests.

Box Crush Test (e.g. BS ISO 12048)

Rectangular Compression Platen for crush/compaction testing imitating a real-life scenario. Image Credit: Stable Micro Systems Ltd

Most boxes are designed to be used in compression and must withstand being stacked under other boxes without falling or collapsing. The box crush test can be used directly to test compression boxes to failure. In this test, a large compression plate is used to apply force on a box until it crumbles.

The corners of the box are usually the controlling factor in box crush strength, and ensuring corners are reliable is the best way to ensure a good stacking strength. A crush test will help to detect poor adhesive penetration, spotty adhesion, and carton board with low bond strength.

During a crush test, a box is subjected to increasing load under a compression platen until failure occurs. Boxes can be crush tested either empty or filled with their intended contents – when full, this is termed ‘in situ testing’.

Box Creep Test (e.g. ASTM D7030)

As boxes are usually stored for a time stacked on top of each other, the bottom package is continually subjected to a constant compression load. Consequently, some manufacturers carry out creep testing.

In this type of test, a Texture Analyser compression platen subjects an empty container to a static load. Deflection-time data is used to predict the time to failure of boxes stored in this manner.

Flat Crush Test (e.g. TAPPI T809)

The rigidity of the fluted structure is essential to corrugated board, and although not necessarily visible from the outside, flute damage will weaken the finished box. Flat crush resistance is a measure of this structure’s resistance to deformation on the corrugator and other converting equipment and will predict whether or not flutes will be damaged during processing.

A low flat crush value will have an effect on the sample’s flexural stiffness and may suggest that a box will not perform as expected.

Edgewise Strength – Ring Crush and Edge Crush

Corrugated board products undergo many varying stresses during their lifetime – mainly crushing forces when they are handled, stored or transported. It is, therefore, useful to know a product’s edgewise compression strength to optimize the manufacturing process.

This ‘column strength’ is often considered to be the most important factor in controlling box strength. Additionally, edgewise compression strength is the main parameter used to determine the dynamic compression strength of a finished box made from the board in question - the edgewise strength of the board along with flexural stiffness relates to the compressive strength of boxes made with vertical flutes.

There are two main methods to test the edgewise strength of a combined board – the ring crush test (which can also be used for its components alone) and the edge crush test, used for completed board only.

Ring Crush Test (e.g. TAPPI T822)

In this test, a specimen is held in a ring form in a dedicated sample holder and compressed by a platen on the test platform of a Texture Analyser. The test is carried out at constant speed until the sample collapses.

As edgewise compression strength of a board can be estimated by adding the ring crush strengths of the liners and medium, this test is especially useful for the R&D process of box making. Potential liner and medium materials can be tested in this way and cataloged to estimate the edgewise strength of different material combinations.

Edge Crush Test (e.g. TAPPI T811)

This test is particularly useful for quickly assessing the strength of different material combinations in a finished board, and helps the box maker to predict the performance of a box using the ‘McKee formula’ which estimates box compression strength.

Pin Adhesion Test (e.g. TAPPI T821)

Another factor that controls the quality of the corrugated board is the strength of adhesion between the corrugating medium and its facings. This adhesion can be measured directly using a ‘pin adhesion test’.

In this test, pins are inserted between the facing and fluted medium, then attached to rigs connected to the loading arm and base. The rigs are pulled apart at constant speed until the facing is separated from the flute tips.

This test assesses the quality of the bond formed when the board was combined and can be used to detect some manufacturing defects such as poor adhesive penetration and spotty adhesive application.

Flexural Stiffness Test (e.g. ISO 5628)

Corrugated board boxes are designed to be stacked on top of each other during storage and transport. When a box is loaded in this way, its walls deflect and bend either in or out. This causes a stress concentration at the box corners, which means the corners have a large part to play in the strength of the box.

However, the deflection of the walls that causes this stress on the corners can be controlled to some extent by ensuring the cardboard has adequate flexural stiffness: a higher flexural stiffness gives a more rigid container and a higher box compression strength.

Flexural stiffness, strength, and deformation to failure can be measured in a bend test, such as three-point bending. In a test such as this, a cuboid sample is placed over two curved supports (termed ‘rollers’) and a third roller is used to apply a load to the center of the sample, halfway between the two support rollers.

Three-point bend testing for flexure analysis imitating a real-life scenario. Image Credit: Stable Micro Systems Ltd

Puncture Test

Some box makers carry out puncture testing, measuring the force or energy required to pierce through cardboard samples. This test ultimately predicts the penetration resistance of a complete box. During a puncture test, a pyramid or conical-shaped tip is pushed into the surface of a cardboard or paper sample suspended over an aperture. Puncture resistance may be reported in terms of force or stress.

Tensile Test (ASTM D828)

Tensile testing is applied to paper products for various reasons to assess strength in use and is used for the combined corrugated board but not as frequently as bending, compression, and puncture.

Tensile testing of a material on a TA.HDplus Texture Analyser. Image Credit: Stable Micro Systems Ltd

In a tensile test, a sample (usually cuboidal or dogbone-shaped) is placed between two grips. The Texture Analyser pulls the grips apart at a constant speed until failure occurs. Properties that can be determined from a tensile test include force and displacement to failure, stiffness and work to failure, and force and distance results may be converted to stress and strain if dimensions can be reliably measured.

There are many variations of paper tensile testing for use as measurement solutions, including perforation testing (ASTM D4987) and wet paper testing (ISO 3781).

Tear Test (TAPPI T470)

Tearing resistance is measured by manufacturers as a means to test paper’s durability. As with puncture testing, there are many advantages associated with the use of a Texture Analyser.

In a tear test, a sample is held in tensile grips and a sample containing a pre-existing notch is pulled apart. ‘Trouser’ tests are also a common testing configuration. Tearing resistance is the force needed to progress a tear perpendicular to the paper sheet.

Other Options from the Standard Method Approach

If you’re not bound by any existing constraints and are looking for the most simple testing solution, sometimes the easiest approach is to set up a test that closely imitates the way the product is evaluated in real life. This is called an ‘Imitative Test’. This type of test usually also makes data interpretation easier for you to understand.

Whilst standard methods are particularly useful for traditional material forms that have not changed over the decades and are fully accepted there lies another world where creativity has taken off into new materials and material forms for which these standard methods cannot be applied.

Not only are new non-standard methods viable where sample dimensions cannot be prepared according to the standard but also where the operator may wish to modify the test parameters (such as the test speed) to more closely mimic the situation under which the sample is to be typically used.

Stable Micro Systems are able to develop bespoke testing solutions based on customer sample dimensions and testing requirements with the ability to analyze data in a number of standard formats or the development of a desired customer analysis technique.

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.