Image Credit: mariolav/Shutterstock.com

Lately, tribology research has expanded swiftly with regards to both range and depth.

As a very multidisciplinary field, tribology typically has developments that distribute across a variety of disciplines. A few of the more significant recent developments are in the areas of lubrication, biotribology, high temperature tribology and computer simulations.

Lubrication

One of the more exciting areas of lubrication research is the growing area of superlubricity, which is described as a system of motion involving little to no rubbing.

Massively lowering the friction coefficient, superlubricity materials and methods greatly decrease the friction-related effects of wear and noise. One of the many most promising superlubricity materials right now is diamond-like carbon (DLC) film. This material has drawn intense research interest within the tribology research community. Key developments related to DLC film have included the development of several new lubricants.

Because of their weak interlayer connection, graphene and similar two-dimensional materials have been the driving force behind a number of recent superlubricity research efforts. Recent developments have achieved superlubricity in many different systems and length scales, in the process exposing a number of new physical mechanisms for the phenomenon.

Biotribology

Biotribology refers to the use of tribology concepts in biological scenarios. Recent developments have ranged from exposing the underlying tribology mechanisms of various organs to applications related to medical treatments.

The biggest percentage of recent studies in biotribology has been related to joint tribology, with both natural and artificial joint systems getting substantial attention. Artificial joint research has primarily focused on the advancement of the wear resistance methods used in clinical settings, including metallic, polymeric and ceramic joint systems. Recent developments have also included research on novel biomimetic materials for joint implants.

While some recent research has shown surface coatings for metallic joints can enhance wear resistance, some coatings have also been shown to reduce the discharge of metallic ions, which is increasingly being seen as a problem related to metallic biomaterials.

For artificial joints, a major recent focus has also been pre-clinical wear testing, with a particular emphasis on creating more authentic and predictive experimental setups. Research has been quite focused on investigating hard metal-on-metal contacts.

Oral tribology has also had a number of developments, and many developments have shared common threads with joint tribology. For example, there has been a number of studies on the importance of corrosion in both joint implants and dental implants. Research has also found the lubricating mechanisms in soft tissues may be similar in both joint and oral systems.

In skin tribology, many recent studies have focused on the tactile perception and friction of the skin. With the tribology of skin being very complex, a multi-disciplinary approach was needed to investigate skin at multiple scales in recent research.

Finally, the use of the engineering principles has expanded significantly in tribology research, extending all the way down to the cellular level.

High Temperature Tribology

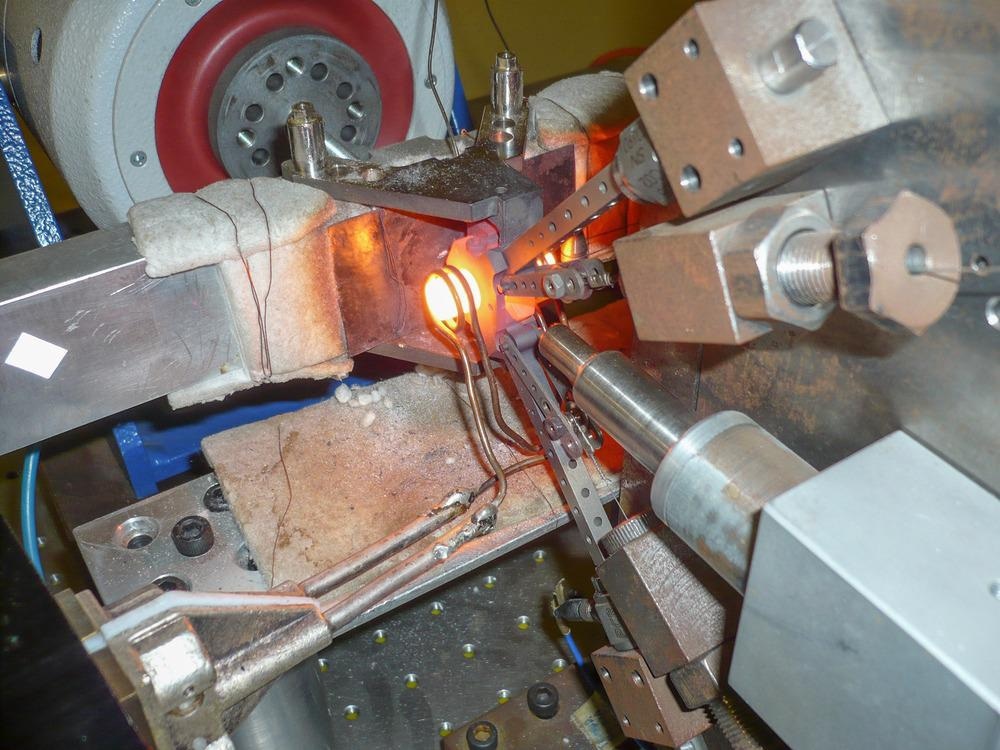

High temperature tribology is pertinent in a number of applications, including in aerospace, automotive and metalworking processes. High temperature tribology is typically a factor during the forceful interaction of two moving, contacting solid surfaces, due to the inherent pressure and friction.

High temperature tribological systems are quite complex, with surface and near-surface factors undergoing major shifts when subjected to high temperatures.

The main thrust of present research has been in creating materials and surface solutions for managing wear and friction at high temperatures, which covers many different applications, opportunities, demands and challenges.

A lot of studies related to the effect of high working temperature on wear and friction have been in the industrial context of press hardening and hot forming areas. The principal basis for this is the demand for lightweight materials to lower fuel consumption in various vehicle types. Researchers have been particularly focused on ultra-high-strength aluminum alloys and boron steel.

Automobiles have many intricate structural and safety parts made of lightweight materials that are challenging to fabricate with traditional methods at room temperatures. During high temperature forming processes, interactions between tools and materials include complex tribological systems. Understanding wear and friction phenomena in this setting are vital to the ongoing development of lightweight vehicle components, longevity of costly forming tools and general productivity in the automotive industry.

Computer and Numerical Simulations

Recently, molecular dynamics simulations and the first-principle calculations that compute atomic relationships via essential quantum mechanics equations have become major new tools for tribology simulations. One recent major focus has been the molecular interactions at surface interfaces, such as the boundary slippage that occurs in lubricant rheology.

While molecular dynamic simulations and first-principle computations are the fastest growing area in tribology simulations, the present computing capability and time scales of simulations can limit complex simulations.

Many recent efforts have looked to integrate multifactorial issues into a singular sophisticated model in order to analyze many different factors simultaneously. While multifactorial simulations are capable of presenting quite realistic results, the associated computational costs can rise rapidly. However, computer simulations have broad applications for forecasting the wear of various systems, including in cutting tools, bearings and artificial joints.

References and Further Reading

Meng, Y. et al. A review of recent advances in tribology. Friction. [Online] Available at: https://link.springer.com/content/pdf/10.1007/s40544-020-0367-2.pdf

Tribonet. So, what is superlubricity? [Online] Available at: https://www.tribonet.org/so-what-is-it-superlubricity/

Centre for Industrial Rheology. Tribology Testing Services. [Online] Available at: https://www.rheologylab.com/services/tribology-testing/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.