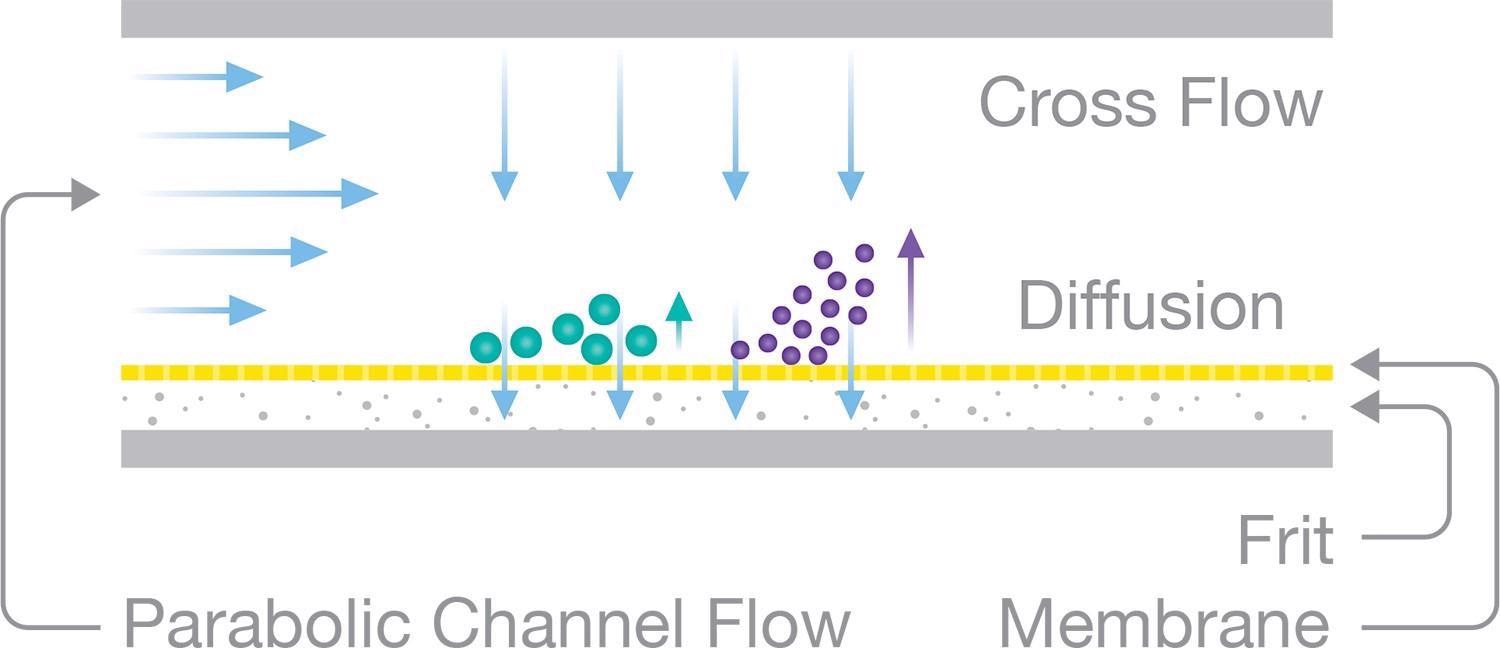

The separation channel is a key component in asymmetric-flow field-flow fractionation, also referred to as AF4 or FFF. In FFF, chromatographic separation takes place in a trapezoidal channel which serves the same function as the column in size-exclusion chromatography (SEC).

Image Credit: Wyatt Technology

Its lower surface area, gentler shear forces and lack of a stationary phase make the FFF channel ideally suited for the separation of large particles and polymers, particularly those that do not always elute properly from an SEC column.

Variable-Height Channels: Flexible and Established Configurations

An interchangeable spacer made from a polymeric material is generally used to define the interior channel height - a key consideration when optimizing FFF separations.

An increase in channel height will enhance resolution and increase sample retention time, providing that other experimental parameters all remain consistent. Spacers are available in variable thicknesses, usually in the range of 250 to 900 µm.

Image Credit: Wyatt Technology

The variable-height channel design is widely used and offers excellent flexibility. This makes it highly suited for method development and a diverse array of lab-based applications. Users are able to switch between spacers of varying thicknesses, allowing them to effectively optimize separation conditions.

This flexibility does come with some downsides, however. Users are required to assemble the channel correctly, employing a torque wrench to ensure proper sealing. The spacer itself is regarded as a consumable, meaning this should be replaced with each membrane change.

Spacers are also prone to compressing up to 100 µm under full channel torque, leading to a smaller-than-expected effective channel height when compared against theory or simulations in VISION DESIGN, requiring verification and correction of the actual channel height in VISION.

Fixed-Height Channels: Convenience and Excellent Reproducibility

In the innovative new fixed-height channels, the spacer is integrated into the top plate. This design of fixed-height channels reduces membrane compression to no more than ~25 µm, because the stainless top and bottom blocks are now in direct contact with each other, resulting in minimal change in actual channel height. Reduction in channel height variability improves reproducibility of separations.

Image Credit: Wyatt Technology

This design also makes the channel assembly much more straightforward: tightening the screws to a very specific torque value using a calibrated torque wrench is no longer required. One need only tighten the screws until the plates are in hard contact using a standard hex screwdriver.

With simple assembly and high repeatability, the fixed-height channels are well suited for routine and QC applications.

Fixed-height channel top blocks are available for Short and Long Channel configurations with heights of 250, 350 and 500 µm, which are comparable to the effective heights of variable-height spacers. The Semi-Prep channel is available with top block heights of 400, 525, 650 and 900 µm, and these channel heights maintain similar separation profiles to the spacers found in the flexible height channels.

If a different height than the originally installed top block is required, the entire top block may be swapped for another with a different channel height. But since most labs use FFF for characterization of similarly sized analytes, it is unlikely that multiple top blocks would be required.

Image Credit: Wyatt Technology

Selecting the Right Channel Type

The choice of channel type will largely depend on the application in question. The fixed-height channel is an ideal choice for applications where there is already a routine FFF method established.

The fixed-height channel is also a prudent choice in applications that require easy channel assembly and high reproducibility of sample runs or in instances where organic solvents or solvent mixtures are used.

The variable-height channel is a good option where users are frequently switching projects, conditions and work primarily with unknown samples.

In either case, it is advisable to use the VISION DESIGN application to develop flow conditions and select appropriate channel heights in silico prior to running any samples.

This information has been sourced, reviewed and adapted from materials provided by Wyatt Technology.

For more information on this source, please visit Wyatt Technology.