Near-infrared spectroscopy (also referred to as near-IR spectroscopy or NIRS) is a spectroscopic technique that focuses its attention on the near-infrared region of the electromagnetic spectrum - 780 to 2500 nm.

Video Credit: Metrohm Middle East FZC

Near-IR spectroscopy belongs to the group of vibrational spectroscopy techniques, along with mid-infrared spectroscopy (primarily FT-IR) and Raman spectroscopy.

The first near-IR spectrometers were developed in the 1980s, initially being designed for industrial applications and chemical analysis. There are two primary forms of NIR analyzers: dispersive NIR (scanning) and Fourier Transform based (FT-NIR) spectrometers.

Dispersive spectrometers fitted with a monochromator and holographic grating offer a number of key advantages.

These instruments combine visible (Vis) and near-infrared (NIR) spectroscopy, meaning that they are able to perform qualitative (identification and qualification) and quantitative analysis of a range of parameters in a single run.

Typical Applications of NIRS

Near-infrared spectroscopy is commonplace in quality control and quality assurance processes where the key goal is to accurately determine samples’ chemical and physical properties.

Use of NIRS can be beneficial in a variety of industries; for example, chemical production, cosmetics, pulp and paper, pharmaceuticals, petrochemicals, polymer production and palm oil.

Quality control applications working with jet fuel, crude oil, or diesel blends are also commonly served by NIRS’ straightforward multiparameter analysis of the critical parameters required for effectively monitoring the refining of hydrocarbons.

Image Credit: Metrohm Middle East FZC

Because NIRS is a non-destructive secondary analysis method, it is especially useful for working with the potentially dangerous or valuable samples found in the petrochemical and fuel industries.

NIRS is an ideal method for monitoring the distillation of crude oil; for example, density, API Gravity, Reid Vapor Pressure (RVP), PIANO measurements, and RON/MON/Cetane Index.

It can also be used when working with lubricant oils, particularly when monitoring aromatics content, PAH, pourpoint, distillation analysis, viscosity, density, flame point, or oil content. When used with diesel blends, NIRS can be used to monitor density, FAME, color, cetan index, cloudpoint, flashpoint and more.

Key Benefits of NIRS

Near-infrared spectroscopy offers a wide range of benefits, particularly over conventional wet-chemical techniques.

NIRS is a rapid technique, able to provide accurate results in under one minute. It does not require the use of potentially toxic reagents or solvents, meaning that it is a greener, more environmentally friendly technique than many of its contemporaries.

NIRS is also non-destructive, and because samples are not chemically altered, damaged or destroyed during analysis, these can be used again.

NIR spectrometers are user-friendly instruments suitable for operation by non-specialists. Users do not require in-depth knowledge of chemical reactions or chemical analysis, and staff training is fast due to the technique’s low user familiarization times.

NIRS offers multiparameter capabilities, and because more than one parameter can be determined with a single measurement, many NIR users report notable cost and time savings over conventional wet chemical techniques.

The break-even point for investment in an NIR spectrometer is typically reached quickly, with return-on-investment (ROI) calculations generally confirming positive outcomes.

Moisture Analysis Options: Karl Fischer Titration and NIRS

Image Credit: Metrohm Middle East FZC

As well as the range of applications and methods outlined above, measurement of water content remains one of the most frequently used determinations in laboratories across the globe. Moisture determination is essential in almost every industry, for example, when working with food and feed, lubricants, or pharmaceuticals.

Moisture content of food and feed must be strictly controlled so that food does not taste stale or dry. It is also important to ensure that moist conditions do not provide a breeding ground for bacteria and fungi, resulting in spoilage.

Determination of water concentration in lubricants is important because excess moisture accelerates wear and tear of machinery.

In the pharmaceutical industry, the water content in solid dosage forms (tablets) and lyophilized products must be monitored closely, with regulations stating that the moisture content in lyophilized products should be kept below 2%.

Figure 1. Water drops in a spider web. Image Credit: Metrohm Middle East FZC

Karl Fischer Titration

Originally introduced in the 1930s, Karl Fischer (KF) titration remains one of the most popular and highly regarded approaches to water content determination. KF Titration is a rapid and highly selective method, meaning that only water is determined.

Figure 2. Manual sample injection for volumetric KF Titration. Image Credit: Metrohm Middle East FZC

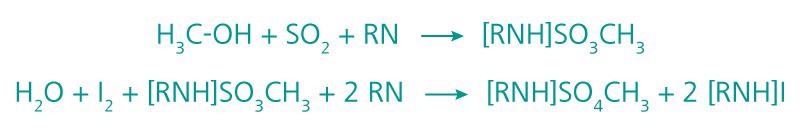

KF titration is based on two redox reactions. The first reaction involves methanol and sulfur dioxide reacting to form the respective ester. Iodine is added, and the ester is oxidized to the sulfate species in a water-consuming reaction. The reaction will end when there is no water left.

KF titration is suitable for water content determination in liquids, solids, slurries, or even gas samples. Volumetric KF titration is the most suitable method when working with concentrations between 0.1% and 100%, while coulometric KF titration is recommended when working with lower moisture content between 0.001% and 1%.

Samples can be added to the titration vessel directly, or these may need to be dissolved in a suitable solvent beforehand, depending on the sample type, its water content and its potential solubility in the KF reagents.

Figure 3. Fully automated KF Titration with the Metrohm 874 KF Oven Sample Processor. Image Credit: Metrohm Middle East FZC

Solvents must not react with the KF reagents, so aldehydes and ketones are unsuitable. A blank correction with the pure solvent should be performed in case the sample is dissolved in a solvent.

The measurement process involves the sample being injected directly into the titration vessel using a syringe and needle. The endpoint is detected using a polarized double Pt pin electrode, and water concentration is directly calculated from this value.

A gas extraction technique and a KF Ooven can be used to analyze insoluble or hygroscopic samples. This process involves the sample being sealed in a small vial, water being evaporated using heat and then the water being subsequently carried to the titration cell.

Near-infrared Spectroscopy

Near-infrared spectroscopy (NIRS) has been widely utilized in food and feed, polymers and textiles since the 1980s, with other industries such as pharmaceuticals, personal care and petroleum products adopting this technique later on.

NIRS can be used to detect overtones and combination bands of molecular vibrations. Typical vibrations in organic molecules for functional groups include -CH, -NH, -SH and -OH, with -OH moiety being a particularly strong near infrared absorber.

Because of this, NIRS has found a central role in moisture quantification applications.

NIR spectroscopy is suitable for the quantification of water in solids, liquids and slurries. The detection limit for moisture in solids is approximately 0.1%, while the detection limit for moisture in liquids is in the range of 0.02% (200 mg/L).

In some cases, such as water in THF, it has been possible to achieve moisture detection limits of 40–50 mg/L.

NIRS does not require sample preparation, meaning that samples can be used as-is. Solid samples are typically measured in high quality disposable sample vials, while liquids are measured in high quality disposable cuvettes.

These different samples are positioned on the analyzer accordingly, allowing a measurement to be taken.

Figure 4: Solid (top) and liquid (bottom) sample positioning for NIR measurements. Image Credit: Metrohm Middle East FZC

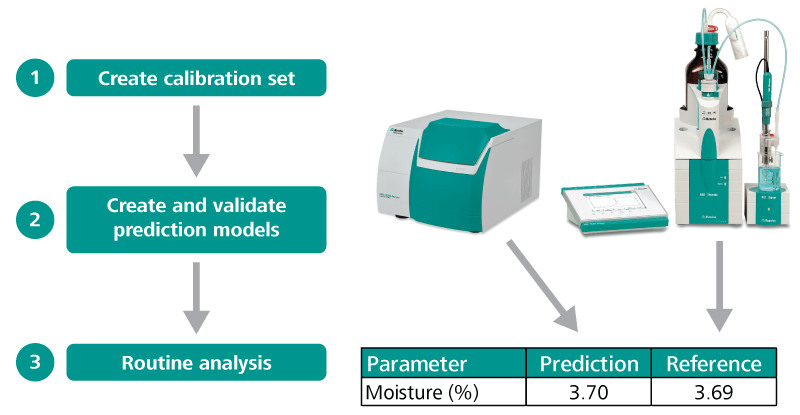

Because NIRS is a secondary technique, it can only be used for routine moisture quantification following the development of a prediction model. This process can be understood as analogous to HPLC, which requires the initial creation of a calibration curve to establish measurement standards. The same principle applies to NIRS: spectra with known moisture content must be measured first, prior to a prediction model being created.

In order to create a calibration set, an average of 30–50 samples must be measured using both NIRS and KF titration, with values obtained via KF titration then linked to the NIR spectra.

Figure 5. Workflow for NIR Method implementation for moisture analysis. Image Credit: Metrohm Middle East FZC

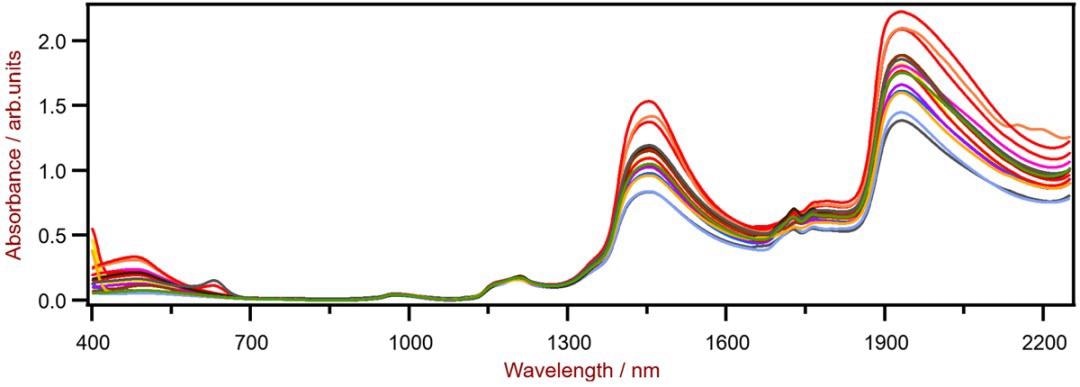

Model development and validation steps are then completed, which are generally straightforward for moisture analysis. Water is a strong NIR absorber, with peaks typically around 1900-2000 nm (combination band) and 1400-1550 nm (first overtone).

Once a prediction model has been created and validated, NIRS can be used for routine moisture determination of that substance. Results of moisture content determination will be obtained in under a minute, without any need for sample preparation or chemical use.

Figure 6. NIR Spectra of moisturizing creams, showing the absorptions related to H2O at 1400–1550 nm and 1900–2000 nm. Image Credit: Metrohm Middle East FZC

This also means that the analyst performing the determination does not need to be a chemist - all they need to do is place a sample on the instrument and press the start button.

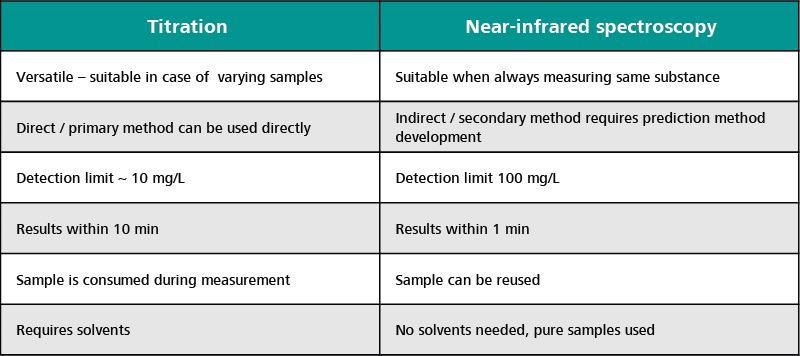

KF Titration, NIRS, or Both?

KF titration and NIR spectroscopy each offer distinct advantages. KF titration is a versatile method offering a low level of detection. Its primary advantage is that it works consistently, regardless of whether the sample type in question is measured regularly or whether it is being encountered for the first time.

Table 1. Overview of characteristics of moisture determination via titration and NIR spectroscopy. Source: Metrohm Middle East FZC

NIR spectroscopy does require a method development process, making it unsuitable for sample types that typically vary, for example, different types of oil or tablets.

NIRS is an excellent method for sample types that are always identical, however, for example, when determining moisture content in lyophilized products or in chemicals, such as fertilizers.

When implementing a NIR moisture method, samples must first be measured using KF titration as the primary method for the model development.

During routine use of an NIR method, it is advisable to continue to use KF titration to periodically confirm (for example, for every 50th or 100th sample) that the NIR model is still robust and that the error rate has not increased.

Should a change in error rate be noted, additional samples should be added to the prediction model to cover the observed sample variation.

Overall, both KF titration and NIR spectroscopy are potent techniques that are well suited to measuring moisture in an array of samples. The best technique to employ depends solely on the application in question and the individual preference of the user.

NIRS Instrumentation from Metrohm

Metrohm offers a comprehensive portfolio of NIRS instrumentation that is suitable for laboratory and process analysis.

Vis-NIR Spectroscopy Lab Analyzers

NIRS lab analyzers from Metrohm are able to perform routine analysis quickly and confidently, with no need for additional reagents or sample preparation.

By efficiently combining visible (Vis) and near-infrared (NIR) spectroscopy, these analyzers can perform qualitative analysis of a range of materials, as well as quantitative analysis of an array of physical and chemical parameters in a single run.

DS2500 Analyzers

Metrohm’s compact DS2500 Analyzers are ideal for rapid QC in a range of industries, including chemical, pharmaceutical, petrochemical, polymer, polyol, palm oil, personal care and pulp and paper.

These instruments are also able to meet a number of key industry standards, including ASTM E1655, ASTM D6342, ASTM D6122, USP 856 and USP 1856 and ASTM D8340-20 (Standard Practice for Performance-Based Qualification of Spectroscopic Analyzer Systems).

Vision Air: Powerful Spectroscopy Software

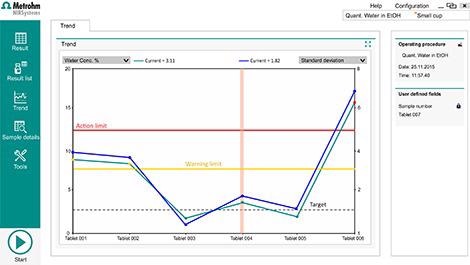

Vision Air is a robust software package that can be tailored to the customer’s specific requirements. The software’s intuitive workflow and contemporary interface simplify daily operations while offering potent monitoring and management functionality ideal for laboratory managers and supervisors.

Measurements are pre-configured and can be launched at the push of a button, while extensive surveillance and filter features ensure that users are able to locate and examine results with ease.

Pre-Calibrations and Turnkey Solutions

A range of ready-to-use calibrations is available, able to streamline applications in the petrofuel, palm oil, polyol and polymer industries. The calibrations include a range of pre-defined parameters, for example, RON/MON, hydroxyl number, viscosity, FFA, density and melt flow rate.

Reliable and Reproducible Results

Traceable NIST standards are used for reference calibration, meaning that Vis-NIR spectrometers from Metrohm are able to yield comparable results regardless of where they are employed. Calibration models may also be transferred between analyzers as required.

Metrohm’s spectroscopy instruments can be used to perform comprehensive analysis of liquids and solids, with instruments capable of fully automated analysis where this is required.

Image Credit: Metrohm Middle East FZC

Metrohm Middle East FZC (MME) based out of Sharjah, UAE is the Regional Support Centre for Metrohm AG (Switzerland) which is responsible for sales, service and calibration of lab & process analytical instruments from the following countries –

UAE, KSA, Kuwait, Bahrain, Oman, Qatar, Egypt, Jordan, Lebanon, Iraq, Bangladesh, Pakistan, Sri Lanka, Ethiopia, Ghana, Sudan, Syria, Yemen, Somalia, Iran, Cyprus, Malta, Eritrea, Djibouti & Afghanistan.

This information has been sourced, reviewed and adapted from materials provided by Metrohm Middle East FZC .

For more information on this source, please visit Metrohm Middle East FZC .