Interview conducted by Olivia FrostJun 7 2021

Interview conducted by Olivia FrostJun 7 2021In this interview, Wes Wigglesworth, the Product Manager at TMC, talks to AZoM about the benefits of using quiet islands over quiet buildings.

Nanofabrication, Semiconductor Fabrication (FABs) and research facilities often incorporate cleanrooms with a system of raised false floors, or raised access floors (RAF) – can you tell us about some of the main advantages and challenges that come alongside using floors such as these?

RAFs are very common and great in many ways particularly for managing airflow in cleanrooms and allowing utilities and humans to be separate. These floors are designed to support typical foot traffic and some lightweight instruments and workstations. Raised floors are not, however, designed to support heavy and/or vibration-sensitive tools that are installed throughout such facilities. A nice feature of an RAF design is that the tiles can be removed and replaced with a tool-specific support pedestal.

What is a Quiet Island® and why is this innovative approach so effective in such facilities?

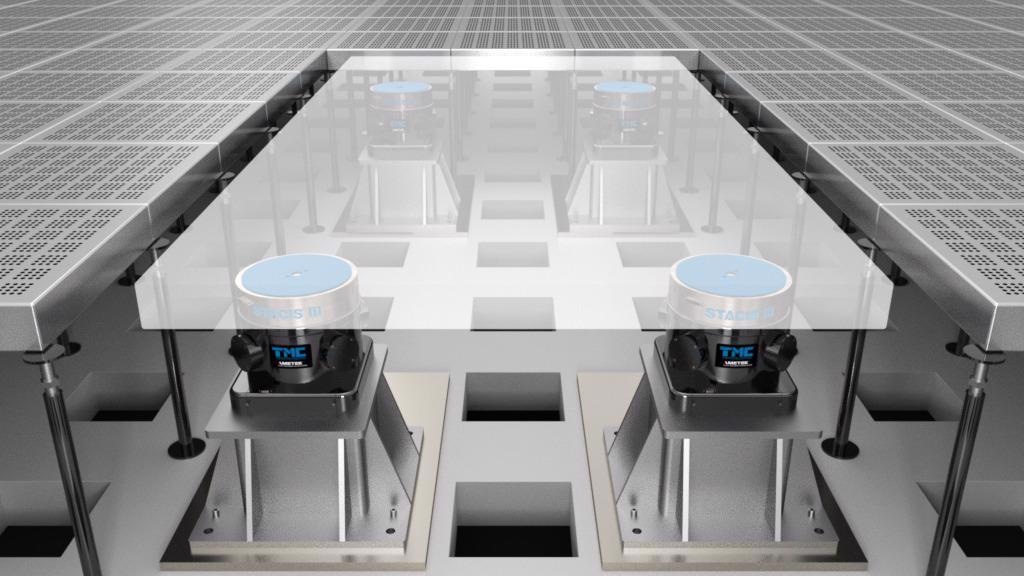

A Quiet Island is essentially a pedestal, an island, replacing the raised access floor, designed to support a sensitive instrument or fabrication tools, such as a Transmission Electron Microscope or a Semiconductor Defect Inspection tool. Its purpose is to isolate the instrument from its surroundings and relatively noisy environment.

A Quiet Island

Image Credit: TMC Vibration Control

A Quiet Island consists of a well-damped steel laminate platform top, support posts typically consisting of active vibration isolation, steel risers to match the RAF height, bridge plates, and other hardware to secure the system properly to the concrete “waffle” floor upon which the RAF is built. When planning the installation of any large, heavy, and/or vibration-sensitive instrument (any instrument with a vibration specification in its installation requirements) a facility manager should consider a Quiet Island. With STACIS®, the Quiet Island provides the instrument with a new floor meeting the vibration requirements for that tool.

What are some of the advantages of using a Quiet Island compared to alternative approaches?

The combination of ease of installation and tuning, low cost of delivery and ownership, environmental impact, ability to customize to the footprint of the tool, modularity, compatibility with its surroundings and the supported tool itself, and, particularly when combined with STACIS, the ability to aggressively attenuate building floor vibration in the 1-4Hz range; when taking all this into consideration, no other single alternative approach comes close. Also, it is much more cost-effective to plan a facility design around the Quiet Island approach rather than to design a Quiet Building, i.e. an entire facility with extremely low levels of vibration. The Quiet Island is the tool-specific support for the tools that need to be installed on a low vibration floor.

Can you elaborate on the benefits of using Quiet Islands over Quiet Buildings?

Cost and flexibility. FABs and most large research facilities house hundreds or even thousands of instruments, with varying levels of sensitivities and environmental requirements. Many defect inspection tools and ebeam lithography tools, for example, require a VC-E (3.12um/s RMS) vibration environment, or even lower. Advanced sensors and high-resolution spectrum analyzers are required to even measure vibration this low. With many instruments not sensitive to vibration, or with much less stringent requirements, it does not make sense to design the entire facility according to the needs of the most sensitive tools – this can get very expensive and highly impactful to the environment. Particularly when the Quiet Island solution is available for the point-of-use, in other words only for the instruments that need it. Why freeze your whole house when you only need one cold beer, right?

These pedestals can be designed to fit the tool footprint without taking valuable extra floor space, can be installed in spaces that were not originally planned for precision instruments, and can be reused or re-purposed if instruments are moved or replaced. I should add that we often hear from folks working in a building that was originally designed to meet a low vibration specification which is later exceeded as the facility matures, additional machinery is added, and activity outside the building increases due to traffic from cars, trains, etc. While a point-of-use solution can still be installed, this reactive approach is much more disruptive, and costly, than planning ahead, particularly for a high-use instrument in a busy, populated facility.

Can you tell us about the support element and core technology utilized in the Quiet Island – the ‘STACIS III Active Vibration Cancellation System’?

STACIS is unique in our industry. At the heart of STACIS is an active feedback control loop consisting of a very low-frequency sensor measuring floor vibration, a sophisticated signal processor, and piezoelectric actuators being driven in response to this signal with equal and opposite force to cancel floor vibration in real-time. A piezoelectric device, often used in precision nanopositioning systems, expands and contracts proportionally to an applied voltage. STACIS uses the same device to cancel low frequency, low amplitude building vibration.

In terms of very short raised floors, how can STACIS IIIc isolators be used instead?

Most RAFs are 18”, 24” or even higher. The compact STACIS IIIc comes in very handy when a facility’s raised floor is less than 15” high.

During the development of Quiet Island, what were some of the challenges you came up against, and how were these overcome?

STACIS was originally developed 25 years ago. Measuring and canceling low frequency, low amplitude vibration in a compact and easy to install package is very challenging. Optimizing the gain over a broadband response while maintaining a stable control signal is perhaps the most challenging aspect. This is something we figured out a long time, and thousands of installations, ago.

How can the Quiet Island help in terms of sustainability?

We hear more and more about carbon footprint, green buildings, and sustainability. An alternative to Quiet Islands is concrete pedestals and large concrete slabs and plinths. Furthermore, when designing quiet buildings, small improvements in vibration require increasing amounts of concrete and steel. The Quiet Island-not-Quiet Buildings approach ultimately uses immeasurable less concrete, a significant contributor to greenhouse gases accounting for roughly 8% of all CO2 discharged in our environment.

Where can readers find more information?

Maturation of Vibration Environment

Quiet Island in Research Facility

STACIS Compact Quiet Islands

About Wes Wigglesworth

Wes Wigglesworth has been with TMC since 1997 and is currently the Product Manager for TMC’s flagship line of Active Vibration and Noise cancellation systems, including STACIS, STACIS iX, Mag-NetX, and the new Everstill.

Wes has previously held positions in Application Engineering, Sales Engineering, and OEM Account Management in the scientific and technology industry over a period of over 24 years.

He holds a bachelor's degree in Electrical Engineering from Tufts University in Medford, MA.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.