The uptake of pumps utilizing diaphragms has increased considerably in recent years as growing numbers of industries recognize the range of benefits that diaphragms offer to the process engineering sector.

AODD (air-operated double diaphragm) and dosing/metering pumps are two distinct types of positive displacement pumps that both utilize diaphragms.

The AODD pump is typically employed in the transfer of higher volume liquids, while the dosing/metering pump finds niche use in the continuous in-phase metering of single or multiple liquid systems moving at varying flow rates.

The increasing demand for mechanically coupled and hydraulically actuated diaphragm pump heads is primarily due to the ongoing development of materials better suited to use in diaphragms.

For example, the availability of synthetic thermoplastic elastomers (TPE) and polytetrafluoroethylene (PTFE) materials suitable for use in diaphragm manufacture has led to new advancements in AODD and dosing/metering pumps.

Each pump type must employ a diaphragm material that is compatible with the fluid being pumped. It is also important that this material is flexible at low temperatures and resistant to deterioration at high pressures and temperatures.

Figure 1. The importance of the diaphragms in an AODD pump cannot be overestimated. Image Credit: Shutterstock

AODD Pump Diaphragms

Over the past 50 years, the AODD pump has grown to become a central solution to complex fluid transfer requirements typical of many industries. The pump’s wide recognition and popularity can be attributed to the technology’s ability to handle a diverse array of liquids with varying characteristics.

Regardless of whether the fluid’s composition is thin, thick, in the form of slurry or particle-free, the AODD pump’s design allows it to pull in the liquid and drive it downstream.

The significance of the diaphragm in an AODD pump cannot be understated - if the diaphragm fails, so does the pump itself. Rather than using rotating parts, diaphragms employ compressed air to pull the liquid media into the pumping chamber before ejecting this.

The only dynamic components to come into contact with the fluid during routine pump operation are the two diaphragms (connected via a common shaft), the two discharge valve balls and the two inlet valve balls.

The diaphragms function as a separation membrane between the fluid and the compressed air supply.

Driving the diaphragms with this compressed air helps balance the load on the diaphragm, removing mechanical stress and prolonging diaphragm life. The valve balls open and close on the valve seats in order to direct the flow appropriately.

The AODD pump is suitable for use at all stages of the liquid transfer production cycle. It can be employed when offloading raw ingredients from tankers or when moving processed or semi-processed product around a plant.

The AODD pump is ideal for use with shear-sensitive fluids, providing a leak-free operation and ensuring that thick and viscous fluids flow consistently.

Choosing an Appropriate Diaphragm Material

The use of an appropriate diaphragm material is essential in maintaining safe pump operation.

Several factors should be taken into consideration when selecting diaphragm materials, including performance, temperature range, abrasion resistance, chemical compatibility, flex-life, sanitary standards, resistance to cleaning fluids, the potential for particle build-up on the diaphragm surface, suction lift, cost and efficiency.

The ongoing and growing need to meet these diverse operational criteria has led to considerable increases in the number of effective diaphragm materials.

Diaphragms remain the most hard-working components in an AODD pump, often expected to work for up to 10,000 hours prior to replacement. Optimum diaphragm flexibility must be maintained throughout their entire operating life if the pump is to continue to operate effectively on start-up.

Plants must prioritize maximum mean time between failures (MTBF) when selecting a diaphragm, ensuring that the diaphragm materials are appropriate to the pump’s operating environment and the fluid being pumped.

It is important to utilize materials that offer an extended flex life because this ensures predictable performance, maintenance schedules and membrane replacement timescales.

Many applications see AODD and dosing/metering pumps open to the elements, so it is also imperative that diaphragms can endure extreme temperatures.

Challenges for Diaphragms

AODD and dosing/metering pumps operate in a diverse array of industries, with each individual industry posing its own set of distinct challenges. Each industry has common requirements which must be met, however.

Pumps must be in a state of readiness when required during the production cycle. They must also provide smooth, accurate and leak-free pumping, alongside minimum maintenance requirements. If these core requirements are not met, there will be adverse effects on the production line efficiency.

High running costs and lifetime cost of ownership can be negatively impacted by pump downtime, product contamination, loss of product, or frequent, repeated replacement of components.

These problems can result in dissatisfied or lost customers, production delays or reduced capacity – all of which will impact the company’s bottom line.

Specific industries such as foodstuffs, personal care products and pharmaceuticals have considerably different requirements to those such as wastewater, chemicals, or paints and coatings.

Surfaces should align with all relevant industry standards while being ultra-smooth (to ensure a smooth flow) and crevice-free (to avoid any solids becoming trapped).

It is also important that materials are not prone to cracking and that they are appropriate for any liquids utilized during clean-in-place procedures.

Even minimal break-up of the diaphragm surface risks cross-contamination of the pumped media. For example, applications where foodstuffs are pumped risk media shearing, splitting or adhering to the diaphragm surface.

Chemical processing applications frequently involve aggressive, abrasive or hazardous pumped media with very low lubricity.

Such challenging media will likely impact the permeability of the surface, potentially resulting in dangerous vapors or volatile organic compounds leaking into the atmosphere or causing damage to vital pump components.

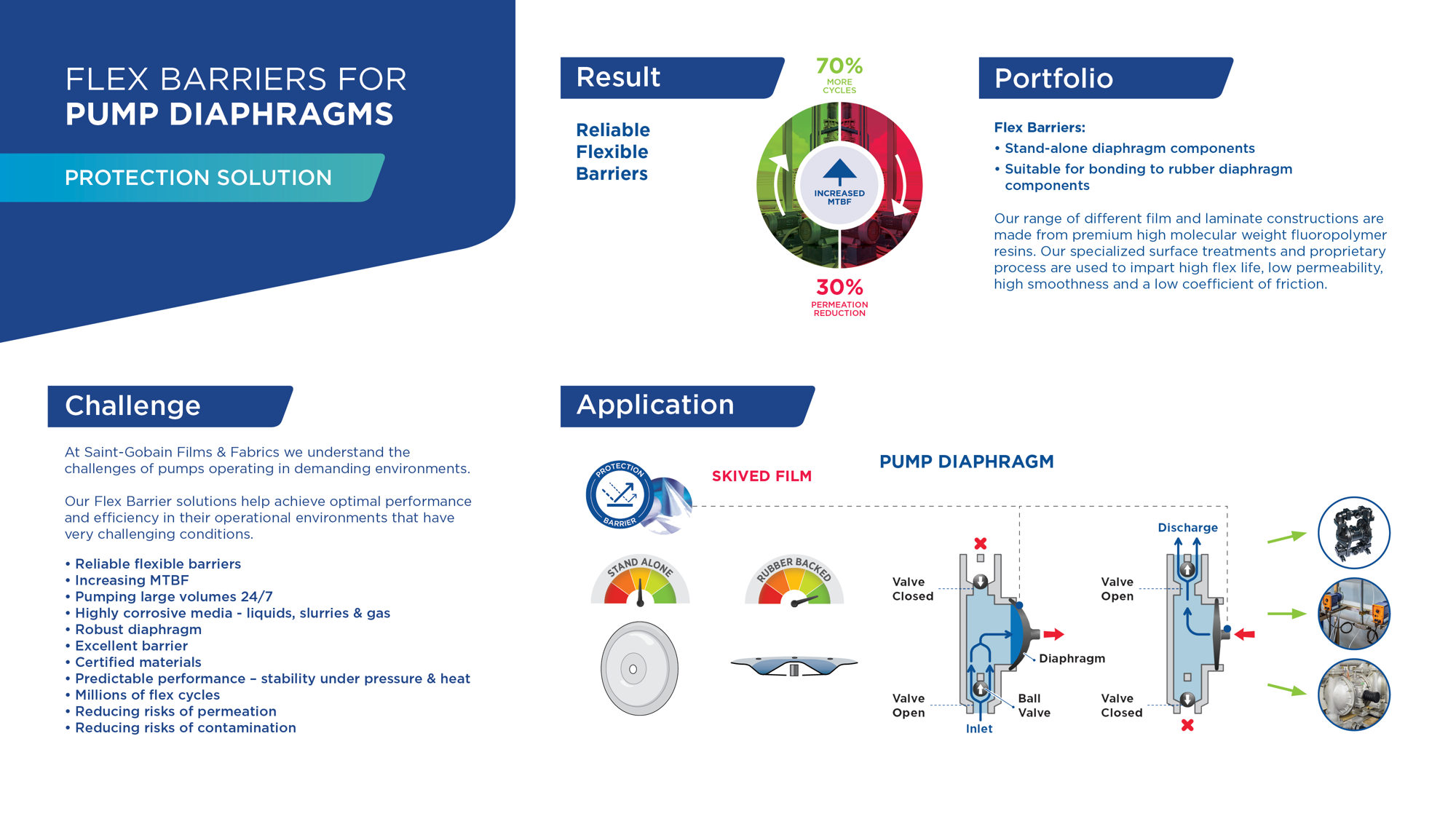

Figure 2. In developing flexible barrier materials, Versiv Composites have concentrated on the issues that impair diaphragm performance. Image Credit: Versiv Composites

Meeting the Challenge

This list of challenges may prompt plants to conclude that there is no solution to this problem and that it must simply be accepted. However, this is not the case.

Key developments and improvements in existing materials have empowered pump users to overcome the challenges outlined here, achieving more cost-effective production and efficiencies to maintain bottom-line profits.

Versiv Composites remains a recognised expert in the development of flexible barriers for diaphragms and is able to address a wide range of challenges across a diverse array of industries.

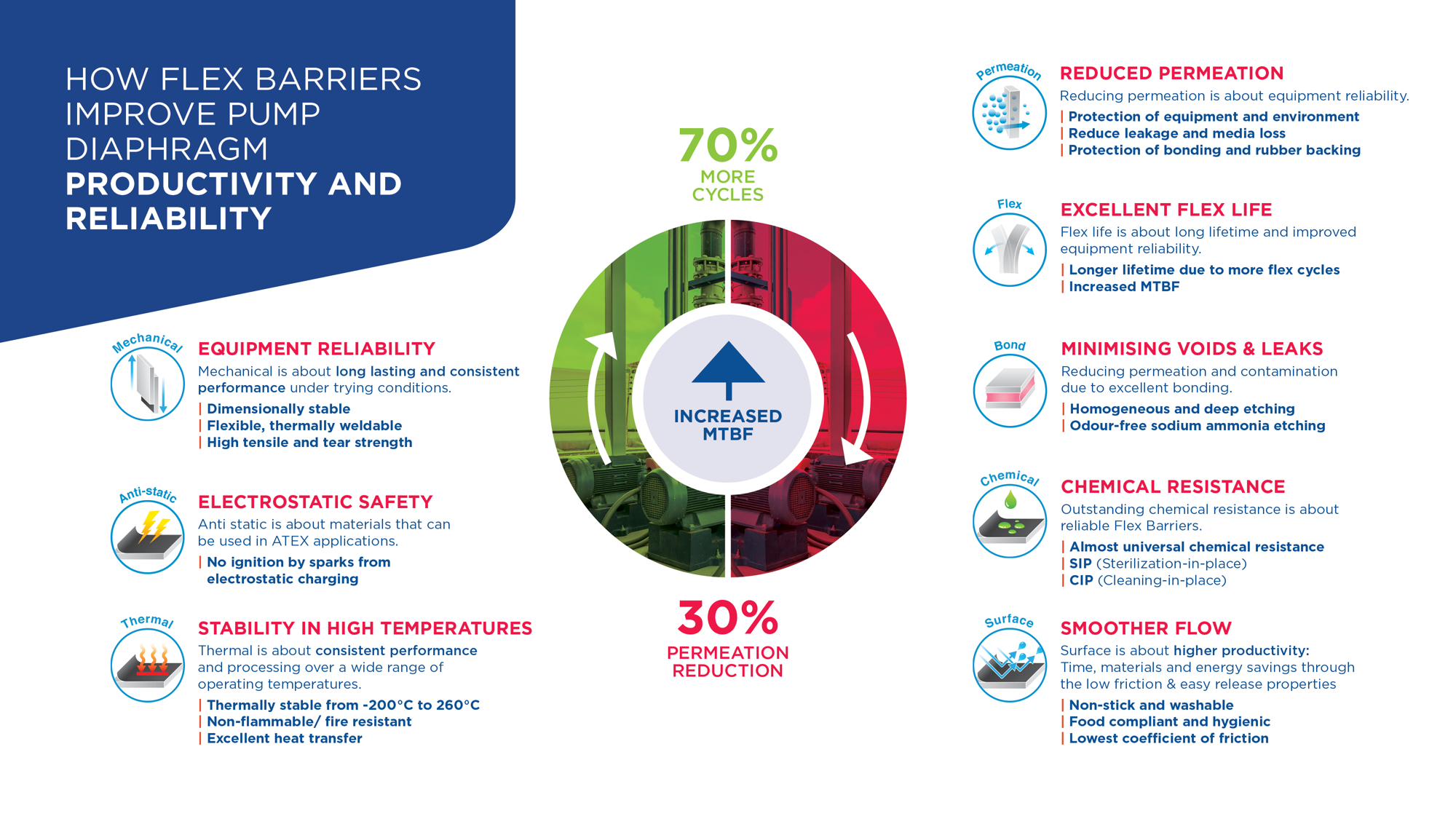

In certain applications, flex cycles and life have increased up to 70% when compared to regular, modified PTFE. Vapor permeability was also found to reduce by 30%.

In developing our flexible barrier materials, Versiv Composites have concentrated on the issues that impair diaphragm performance, the results being products that increase MTBF, improve productivity and extend pump working life through greater reliability.

Frank Sonnenschein, Global Business Development Manager, Versiv Composites

Sonnenschein continued, “Compliance to all relevant international standards has been a priority in the development of Flex Barriers and developing the range of industries served. Our Flex Barriers have practically universal resistance to chemicals and highly aggressive media such as aromatic or chlorinated hydrocarbons, acids, caustics, ketones and acetates.”

The company’s Flex Barriers meet all key regulatory requirements essential in food and beverage, pharmaceutical, sanitary and medical applications.

These include FDA21 CFR177.1550, (EC) No.1935/2004, (EU) No.10/2011, (EC) No.23/2006 (GMP), USP Class VI and 3-A Sanitary Standard.

The materials also align with REACH (EC) No.1907/2006 and RoHS (2011/65/EU) regulations, meaning that these do not feature hazardous or prohibited compounds that could limit the materials’ use in products.

Versiv Composites utilizes a proprietary process and highly specialized surface treatments to deliver Flex Barriers that exhibit low permeability, high flex life, high smoothness and a low coefficient of friction.

This process delivers products that can be thermoformed by customers, allowing them to produce a diaphragm that meets their specific size requirements.

Special surface treatments allow the films to be employed in high-integrity bonding to the customer’s carrier diaphragm (usually rubber) before it is thermoformed and vulcanized. This process can normally be completed in a single operation. It is also possible to pre-form the PTFE barrier prior to vulcanization.

Versiv Composites Flex Barriers can be supplied to manufacturers of pump diaphragms in rolls or as sheets appropriate for stand-alone diaphragm components.

Issues Addressed

PTFE rupture - a common cause of premature diaphragm failure - can be solved by the extraordinary flex life performance of Versiv Composites' Flex Barriers.

An often underappreciated benefit of these Flex Barriers is their gradual mode of failure as opposed to catastrophic, which means the sites have a chance to organise maintenance/ replacement in a planned manner rather than having to deal with a sudden ‘line shutdown’ and material losses.

Frank Sonnenschein, Global Business Development Manager, Versiv Composites

The use of these Flex Barriers also eliminates the risk of damaging media permeation and diaphragm delamination from poor and inconsistent bonding of PTFE and rubber. This results in excellent durability and a considerably reduced stretch void index.

Risks of contamination due to a diaphragm’s rough surface are also eliminated thanks to the barrier’s smooth, inert surface, while the barrier films’ flexibility and quality helps mitigate issues around stiff and heterogenous materials in deep drawing manufacturing.

Figure 3. Significant advances in the development and refinement of flexible barrier materials for diaphragms can solve challenges faced by AODD and dosing/metering pumps. Image Credit: Versiv Composites

Successful Applications

Gottlob Dietz is a diaphragm manufacturer that has seen considerable benefits from the use of Versiv Composites.

The company has leveraged the quality and reliability of Flex Barriers, increasing the overall reliability and lifetime of diaphragms for their global customers. Gottlob Dietz switched to the new Flex Barriers in the hope of decreasing risks of failures from disc rupture and delamination between PTFE and rubber backing on pharmaceutical dosing pumps.

The use of Flex Barriers was successful in increasing flexibility and lifetime while exhibiting improved permeability resistance and enhanced bonding strength with the rubber backing.

The Ariane Group encountered a number of problems in its Ariane 5 space program, including diaphragm rupturing during thermoforming, insufficient chemical resistance to rocket fuels and permeation issues.

These problems affected the entire program not only due to costs but mainly to safety reasons. Working together, we solved these problems through the co-development of a multi-layer fluoropolymer laminate solution.

Frank Sonnenschein, Global Business Development Manager, Versiv Composites

Ariane was able to resolve this significant safety issue through the use of Flex Barriers, allowing its rocket to enter space with a more effective fuelling system.

Throughout this partnership, Versiv Composites has continued to develop increased and previously unachievable levels of formability.

The overall mechanical robustness of these materials has also increased the viability of substituting steel diaphragms in order to reduce pump size and costs.

Figure 4. The Ariane 5 space programme has been a beneficiary of Flex Barriers. Image Credit: Shutterstock

Acknowledgments

Produced from materials originally authored by Frank Sonnenschein from Versiv Composites.

This information has been sourced, reviewed and adapted from materials provided by Versiv Composites.

For more information on this source, please visit Versiv Composites.