Pasta’s mechanical properties are key to its use and popularity. Pasta is very brittle and stiff in its dried form, but its properties significantly change when it is introduced into a humid environment and heated.

. Image Credit: PerkinElmer Food Safety and Quality

This article looks at the effect of humidity on pasta under different isothermal and temperature scanning conditions.

Dynamic Mechanical Analysis (DMA) is a technique for measuring the stiffness of a material. Pasta’s stiffness provides a good indication of the dried product’s stability. While dried pasta from the packet is relatively stiff, the introduction of humidity and temperature will cause its stiffness to decrease as the material softens.

The modulus offers insight into the stiffness as it decreases, while tan δ highlights at what point the material becomes less elastic and more viscous.

The DMA technique involves applying an oscillating force to the material and a measurement of the resultant displacement of the sample. Stiffness can be determined from this measurement, allowing the modulus and tan δ to be calculated.

Tan δ can be understood as the ratio of the loss modulus to the storage modulus.

Measuring phase lag in the displacement and comparing this to applied force facilitates the determination of the material’s damping properties. Tan δ will be plotted against temperature, with glass transition typically observed as a peak. This is because the material absorbs energy while moving through the glass transition.

Dried pasta may be stored for prolonged periods with no risk of biological decay. When exposed to water – via humidity or by immersion - the pasta will absorb the water and begin to hydrate. This hydration rate is impacted by humidity and temperature.

Experimental

Isothermal Experiment at 50 °C and 100% RH

For this experiment, a sample was mounted in a PerkinElmer® DMA 8000’s Single Cantilever Bending clamps. The temperature was set to 50 °C, and the experiment commenced when the humidity reached 100%.

Temperature Scanning Experiment at 62% and 100% RH

For this experiment, a sample was mounted in the DMA 8000’s Single Cantilever Bending clamps, and the RH was permitted to equilibrate. Samples were run from ambient temperature to more than 100 °C.

Source: PerkinElmer Food Safety and Quality

| Equipment |

Experimental Conditions |

| DMA 8000 |

Sample: |

Pasta |

| Fluid Bath |

Geometry: |

Single Cantilever Bending |

| Humidity Generator |

Dimensions: |

2.75 (l) x 4.50 (w) x 0.83 (t) mm |

| Circulator |

Frequency: |

1 Hz |

Results and Conclusion

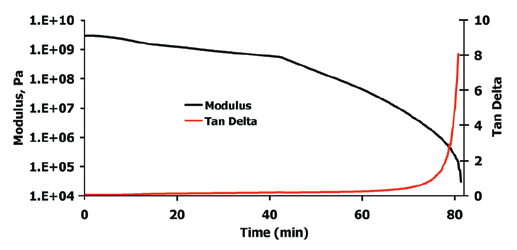

Figure 1 displays the modulus and tan δ response from a pasta sample at 50 °C and 100% RH. The modulus begins to decrease almost instantaneously upon exposure to the RH, losing all integrity at approximately 1.5 hours.

Figure 1. Modulus and tan δ from a sample of pasta at 50 ˚C. Image Credit: PerkinElmer Food Safety and Quality

The tan δ can be seen to increase steadily over the course of the experiment, suggesting that the sample becomes increasingly viscous and less elastic until 1.5 hours when the sample fully collapses.

The shoulder present at 40 minutes indicates the “al dente” point where the pasta is fully hydrated yet maintains a relatively firm texture.

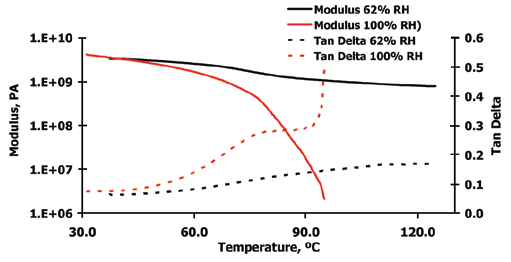

Figure 2. Modulus and tan δ from two temperature scanning experiments. Image Credit: PerkinElmer Food Safety and Quality

Figure 2 displays responses from both temperature scanning experiments, with black lines corresponding to the experiment at 62% RH and red lines corresponding to the experiment at 100% RH.

The modulus in each experiment begins at around the same level, confirming that similar material was examined.

As anticipated, the higher RH experiment demonstrates a more rapid reduction in modulus, ultimately losing structural integrity at around 100 °C. The 62% RH experiment demonstrates a smaller drop in modulus over the temperature range.

The 100% RH modulus response shows a similar shoulder at 75 °C. This indicates the pasta reaching “al dente” point in line with the first graph.

The tan δ response in the 62% RH experiment demonstrates a continuing increase, highlighting increasing viscosity. This is not a constant increase (like the modulus response), suggesting that multiple processes are involved.

This process is more overt and more rapid for the 100% RH sample. A peak is observed at around 75 °C – potentially a plasticized relaxation event and corresponding to the “al dente” point. The sample becomes very viscous as it begins to “cook” at around 100 °C.

These experiments clearly show the DMA 8000’s capacity to perform measurements under a controlled humidity environment. The pasta in this study demonstrated notable mechanical effects as the samples’ temperature, and humidity were controlled and altered.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.