Optimized for the testing of viscous properties, the Rapid Visco Analyzer (RVA) is a cooking stirring viscometer featuring variable shear profiles and ramped temperature.

Image Credit: PerkinElmer Food Safety and Quality

The instrument offers a range of international standard methods and can also accommodate custom-made profiles. Its combines speed, flexibility, precision and automation; offering users a considerable advantage in product development, quality and process control and quality assurance.

The RVA is also highly suited to a range of applications, including:

- Assessment of the cooked viscosity of ground materials, including:

- Carbohydrates, such as flour, starch and wholemeal

- Proteins, including milk, soy and gluten

- Gums

- Plastics

- Quality control

- Comparisons between samples; for example, examinations of competitive products

- Assessments of amylase activity in flour

- Investigations into the impact of formulation

Description

The quality of traditional raised (pan) bread can be improved via the addition of a low level of amylase activity in wheat flour.

The diastatic power of wheat is typically low, meaning it can be improved through the addition of malt flours or fungal amylase. Dextrins are released by the amylase, supporting the fermentation stage of baking.

The Stirring Number method can be utilized in the assessment of malt flour activity from both wheat and barley. A separate method should be used to assess fungal amylase activity.

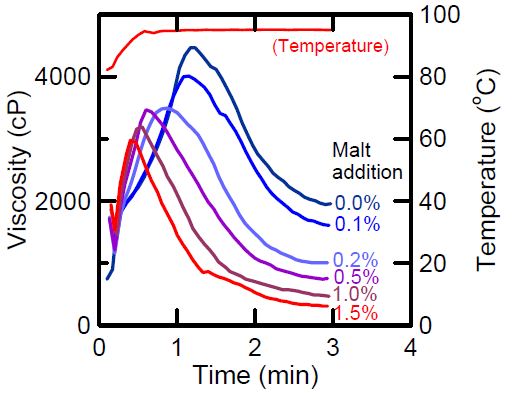

Figure 1. Stirring Number curves of wheat flours (4.00 g flour) with various levels of malt flour addition. Image Credit: PerkinElmer Food Safety and Quality

Method

The Stirring Number method was employed in this study.

Sample Preparation

A total of 4.00 g of flour was prepared at 14% moisture. This contained the malt flour amylase enzyme alongside 25.0 ml distilled water.

Profile

Source: PerkinElmer Food Safety and Quality

| Time |

Type |

Value |

| 00:00:00 |

Temp |

95 °C |

| 00:00:00 |

Speed |

960 rpm |

| 00:00:10 |

Speed |

160 rpm |

| 00:03:00 |

End |

- |

Idle Temperature: 95 ± 1 °C

Time Between Readings: 2 s |

Measure

FV: Final viscosity (RVU or cP)

The FV (in RVU) can be understood to be the Stirring Number (SN), with higher SN values implying lower amylase activity.

Flours including optimum levels of malt flour activity will typically return SN values between 50 and 90 RVU.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.