The Rapid Visco Analyzer (RVA) is a cooking stirring viscometer that features efficient ramped temperature and variable shear profiles.

Image Credit: PerkinElmer Food Safety and Quality

It has been optimized for testing a range of viscous properties and includes several international standard methods while being sufficiently flexible to also accommodate custom-made profiles.

Its distinct combination of precision, speed, flexibility and automation makes the RVA an ideal tool for quality and process control, quality assurance and product development.

The RVA is also useful in a range of applications, including:

- Monitoring and controlling dryer effects on pasta quality

- Monitoring and ensuring the consistency of ingredients between production batches

- Examining and assessing competitive products

Description

The pasting behavior of pasta is largely dependent on the effects of ingredients and processes. The cooking properties and final quality are impacted by treatments during the manufacturing processing, for example, sheeting, drying or extruding. Final product quality may also be affected by protein-starch interactions.

The Critical Paste profile method sees the pasta heated to slightly above its pasting temperature before maintaining this temperature for the duration of the test.

Controlled heating is a beneficial technique when looking to differentiate between manufacturing processes, such as the wheat grade used and the drying regime.

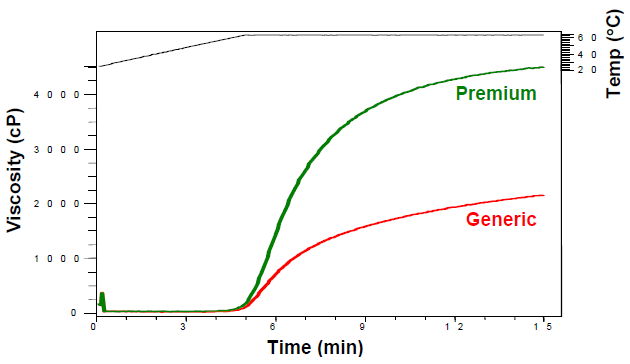

This study observed that a premium (name brand) pasta demonstrated a higher viscosity response than a generic (no name) pasta, indicating that that the generic pasta could have been manufactured from durum with weak gluten that was unable to ensure a good viscosity response.

These findings mean that when the pasta is cooked at temperatures higher than the temperature used in the Critical Paste profile, the generic pasta is prone to breaking apart under stress. For example, when a sauce is being stirred into the pasta.

Figure 1. Pasting curves of premium and generic pasta using the Critical Paste profile. Image Credit: PerkinElmer Food Safety and Quality

Method

A two-step testing method was employed in this study: Sweep Profile and Critical Paste Profile.

Sample Preparation

A total of 6.00 g ground pasta was prepared at 14% moisture. A total of 25.0 ml of distilled water was also used for each profile.

Profile

Sweep

Table 1. Source: PerkinElmer Food Safety and Quality

| Time |

Type |

Value |

| 00:00:00 |

Temp |

50 °C |

| 00:00:00 |

Speed |

960 rpm |

| 00:00:10 |

Speed |

160 rpm |

| 00:15:00 |

Temp |

95 °C |

| 00:15:00 |

End |

|

Idle Temperature: 50 ± 1 °C

Time Between Readings: 4 s |

Critical Paste

Table 2. Source: PerkinElmer Food Safety and Quality

| Time |

Type |

Value |

| 00:00:00 |

Temp |

25 °C |

| 00:00:00 |

Speed |

960 rpm |

| 00:00:10 |

Speed |

160 rpm |

| 00:05:00 |

Temp |

PT from Sweep Profile* |

| 00:15:00 |

End |

|

Idle Temperature: 25 ± 1 °C

Time Between Readings: 4 s |

*PT = pasting temperature (°C)

Measure

Measurements were performed as follows:

- PT: Pasting temperature (°C)

- V6: Viscosity @ 6 minutes (cP)

- V10: Viscosity @ 10 minutes (cP)

- FV: Final viscosity (cP)

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.