Where Is It? Wednesday

Carbolite Gero’s Augmented Reality (AR) technology allows the TSO rotary reactor tube furnace to be virtually placed in any location, empowering users to visualize potential instrument placement with ease and see first-hand how the TSO’s sleek aesthetic can complement any working environment.

Click here to enter on Carbolite's website

The company is offering TSO users the opportunity to showcase their creativity and win excellent prizes in its new competition. Humor, unusual placements and interesting locations are recommended and encouraged.

Image Credit: CARBOLITE GERO Ltd.

The best, most creative entries have the opportunity to win some amazing prizes:

- One grand prize winner will win an 11” 2021 iPad Pro featuring an M1 chip and 256 GB storage (announced on 12th November 2021).

- Three monthly winners will each win a £100 Apple or Amazon gift card (announced on 3rd September, 1st October and 5th November 2021).

For a chance to win, simply access the Carbolite Gero website using a device that can open Augmented Reality files (a recent iPhone, iPad, Samsung Galaxy, etc.). Open the Augmented Reality file for the Carbolite Gero TSO, take a screenshot or video capturing the TSO in an interesting, creative setting and upload this via the form on the company’s website.

Image Credit: CARBOLITE GERO Ltd.

Introducing the TSO Rotary Reactor Tube Furnace Range

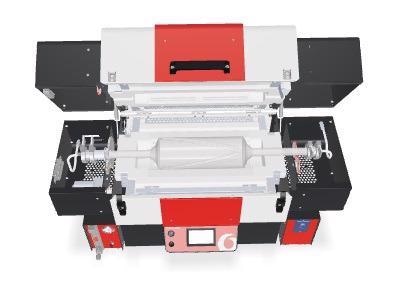

The new TSO rotary reactor tube furnace range from Carbolite Gero offers truly versatile, first class performance thanks to its use of high quality heating elements coupled with an innovative thermal insulation design – also helping reduce case temperatures and power consumption.

The TSO tube furnace body is divided into two halves and hinged at the rear. Pneumatic dampening struts positioned at each end ensure a smooth opening action. Because the furnace can be opened, operators can easily insert reactor vessels with end flanges; a that would pose challenges when working with a non-split furnace.

The TSO rotary reactor tube furnace has been designed and developed to facilitate effective processing or testing of granular or powdered materials at high temperatures.

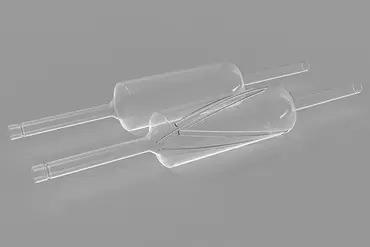

The furnace features a quartz vessel for material insertion while a variable speed drive system allows the vessel to be rotated within the heated zone by 314°, creating a smooth oscillatory motion.

A number of optional accessory packages are also available; for example, standard or fluted vessels and add-ons to allow operation under air or a modified gas atmosphere.

Key Features

The furnace boasts the following core features:

- Maximum temperature: 1100 °C

- Reactor vessel Ø: 120 mm

- Heated length(s): 400, 600, 800, 1000 mm

- Number of heated zones: 1 zone or 3 zones

- Orientation: horizontal

Leading Heat Technology

The new tube furnace range from Carbolite Gero is the result of over 80 years of experience in thermal engineering and represents the cutting edge of furnace design. The range combines the latest technological advances with robust construction, high quality components and a sleek, contemporary aesthetic.

The TSO rotary reactor’s oscillatory motion improves the exposure of sample material to the atmosphere within the vessel, improving both reaction times and overall yield.

Image Credit: CARBOLITE GERO Ltd.

High Quality Heating Elements and Low Energy Consumption

The TSO rotary reactor tube furnace boasts excellent temperature uniformity along the entire heated length, as well as rapid heat-up and cool-down rates. Its unique combination of low energy consumption and low external case temperature ensures a long service life, even under challenging operating conditions.

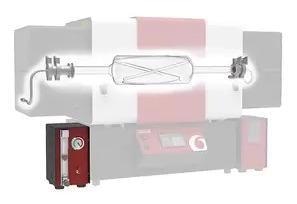

Temperature Control and Communications Options

TSO rotary tube furnaces are fitted with ethernet communications and feature a standard programmable controller with 24 segments:

- Single zone furnaces are fitted with a Carbolite Gero EPC3016P1 controller

- Three zone furnaces are fitted with a Carbolite Gero CC-T1 touch-screen controller

A range of multi-segment programmers, advanced digital controllers, and data loggers is available, featuring RS232, RS485 or ethernet communication options.

Over-temperature protection is available and is advisable when working with valuable contents or operating the furnace unattended.

CC-T1 Touch Screen Controller. Image Credit: CARBOLITE GERO Ltd.

Modified Atmosphere Options

The Carbolite Gero TSO rotary reactor tube furnace range may be equipped with gas connections to accommodate modified atmosphere applications.

Standard or fluted reactor vessels are available, and a gas connection kit can be provided to facilitate operation under modified atmospheres. The use of inert gas package modules enables up to three non-reactive gases to be employed, either via manual or automatic control.

Image Credit: CARBOLITE GERO Ltd.

Image Credit: CARBOLITE GERO Ltd.

Mounting Configurations

The TSO range of tube furnaces can utilize two standard mounting configurations:

- Heated lengths up to 600 mm should mount the furnace body on top of the control box, allowing it to be easily be detached and moved for remote operation.

- Heated lengths of 800 mm should ensure that the furnace body and control box are always kept separate.

Both of these configurations include a 2 meter cable with a plug and socket. This cable is designed to reach between the furnace body and control box. An optional 4 meter extension cable is also available, providing a total reach of 6 meters.

This flexible arrangement enables easy conversion to optional mounting; for example, attaching a mounting bracket or inserting the instrument inside a fume cupboard.

Furnace body on top of control box. Image Credit: CARBOLITE GERO Ltd.

Detachable furnace body. Image Credit: CARBOLITE GERO Ltd.

Furnace body and separate control box. Image Credit: CARBOLITE GERO Ltd.

Option: 4 M cable extension. Image Credit: CARBOLITE GERO Ltd.

Technical Data

| |

Max temp (°C) |

Number of heated zones |

Reaction chamber dimensions (mm) |

Reaction chamber capacity (ml) |

Oscillation frequency per min |

Rotation in each direction |

Dimensions: External H x W x D (mm) lid closed |

Dimensions: External H x W x D (mm) lid open |

Max power (W) |

Weight (kg) |

| TSO1 11/400 |

1100 |

1 |

Ø 120 x 330 |

620 |

1 to 8 |

315° |

665 x 1115 x 575 |

930 x 1115 x 655 |

1860 |

88 |

| TSO1 11/600 |

1100 |

1 |

Ø 120 x 530 |

990 |

1 to 8 |

315° |

665 x 1315 x 575 |

930 x 1315 x 655 |

2510 |

106 |

| TSO1 11/800 |

1100 |

1 |

Ø 120 x 730 |

1360 |

1 to 8 |

315° |

445 x 1515 x 575* |

705 x 1515 x 655* |

3160 |

119 |

| TSO1 11/1000 |

1100 |

1 |

Ø 120 x 930 |

1740 |

1 to 8 |

315° |

445 x 1715 x 575* |

705 x 1715 x 655* |

3810 |

137 |

| TSO3 11/600 |

1100 |

3 |

Ø 120 x 530 |

990 |

1 to 8 |

315° |

665 x 1315 x 575 |

930 x 1315 x 655 |

2510 |

106 |

| TSO3 11/800 |

1100 |

3 |

Ø 120 x 730 |

1360 |

1 to 8 |

315° |

445 x 1515 x 575* |

705 x 1515 x 655* |

3160 |

119 |

| TSO3 11/1000 |

1100 |

3 |

Ø 120 x 930 |

1740 |

1 to 8 |

315° |

445 x 1715 x 575* |

705 x 1715 x 655* |

3810 |

137 |

Content may be subject to modifications or corrections

This information has been sourced, reviewed and adapted from materials provided by CARBOLITE GERO Ltd..

For more information on this source, please visit CARBOLITE GERO Ltd..