In a high number of cases, hydrogen sulfide gas is created as a byproduct of raw material manufacturing or water treatment processes.

However, the corrosive gas can be damaging if left untreated. Most facilities use scrubbers to offset the dangerous gas prior to atmospheric release.

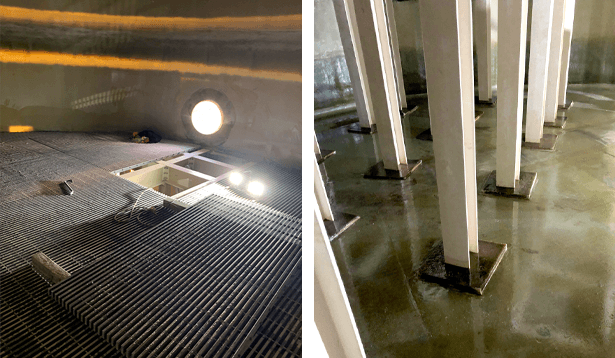

Image Credit: Strongwell Corporation

For this reason, a pulp processing company wished to install a new H2S vertical packed bed scrubber measuring 26' in diameter and 55' in height at one of their sites in Alberta, Canada.

Since the late 1980s, operations of the pulp mill have overseen the capture and conversion of biogases for onsite renewable electricity usage.

This type of scrubber utilizes air pressure and water to recirculate the captured gases into the compacted bedding system for additional processing within an operational temperature range of -40°C to +40°C so that the gases can be filtered for renewable electricity.

The customer employed Structural Composite Technologies (SCT), a company located in Winnipeg, Manitoba, because of its sixty years of experience designing, fabricating and assembling industrial designs within the manufacturing milling, mining, refining and smelting sectors.

Image Credit: Strongwell Corporation

For this specific scrubber tank support application, SCT’s objective was to guarantee lasting structural integrity paired with outstanding corrosion resistance.

EXTREN® Series 625 wide flange and I-beams were utilized to hold up 2" DURAGRID® HD-6000 pultruded grating with 6" cross-rod spacing. In combination, these two products keep all the packing material inside the scrubber.

As an additional step, to avoid a chemical attack, the components were fastened mechanically with Hastelloy instead of 316L grade stainless steel.

Strongwell collaborated with SCT in designing, fabricating and piece marking the platform’s components to make sure that the sections could be easily put in place upon delivery without the need for additional fabrication.

At the end of this project, SCT and the other companies involved praised the general supply, delivery and design experience of the scrubber’s internal FRP platform.

Table 1. Technical data. Source: Strongwell Corporation

| . |

. |

| Product: |

H2S Scrubber Tank Support Structure |

| Process: |

Pultrusion, Fabrication |

| Materials & Sizes: |

- 2" DURAGRID® HD-6000 Pultruded Grating

- EXTREN® Series 625 Structural Shapes:

|

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.